100 кг 200 расплавленный чугун алюминиевый лом Металл плавильная индукционная

- Категории: Промышленные печи >>>

- Поставщик: Luo,Yang,Hongteng,Electrical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

1t scrap steel iron induction casting Melting furnace

Advantages of induction casting furnace

1, the device is small, light weight, high efficiency, low power consumption;

2, low temperature around the furnace, less smoke and dust, good working environment;

3, the operation process is simple, reliable smelting operation;

4, the heating temperature is even, less damage, metal components;

5, the casting quality is good, the melting temperature rises quickly, the furnace temperature is easy to control, and the production efficiency is high;

6, high furnace utilization, easy to replace varieties.

Melting furnace Part :

1. aluminum shell furnace body

2. reducer auto tilting

3. copper tube induction coils inside

Technical Parameter of induction melting furnace | ||||||||

Model | MF power | Input voltage | MF Voltage | MF frequency | ||||

100KG | 80kw | 3ph,380V | 750V | 2500HZ | ||||

250KG | 150kw | 3ph,380V | 750V | 2500HZ | ||||

350KG | 250kw | 3ph,380V | 750V | 2000HZ | ||||

500KG | 350kw | 3ph,380V | 1500V | 1500HZ | ||||

750KG | 400kw | 3ph,380V | 1500V | 1500HZ | ||||

1T | 800kw | 3ph,380/660V | 2400V | 1000HZ | ||||

1.5T | 1000kw | 3ph,660V | 2500V | 1000HZ | ||||

2T | 1500kw | 3ph,660V | 2500V | 800HZ | ||||

Applications of induction melting furnace

1. Induction metal melting furnace mainly used for melting cast iron, cast steel , copper and aluminum alloy scrap for casting dies.

2. Induction metal melting furnace can also be used together with selfheated furnaces and electric arc furnace for heating orkeeping warm the molten iron and molten steel.

3. induction metal melting furnace is applicable to melt steel , cast iron , copper, aluminum and other metals.

4. induction metal melting furnace can be produced with different volume , such as 150kg ,250kg ,350kg ,500kg ,750kg ,1000kg ,2000kg etc...

5. induction metal melting furnace has 1650C operation temperature .

6. induction metal melting furnace will be matched with metal liquid ladle if customer need

WE HAVE RICH EXPERIENCE IN PRODUCING INDUCTION FURNACE MOST FURNACE USED IN FOLLOWING APPLICATIONS:

1. Melting steel ,iron, copper ,aluminum, zinc,

2.Used in forging factory. Heating furnace most used for preheat material before forge.

3.Used in 3PE anticorrosion production line.Heating furnace use for heating pipe before coating.

4.Used in Rebar production line.Heating furnace most used for reheat the billets to high temperature before goes into rolling mill.

2. Medium frequency heating furnace

3. Dialing pipe device

4. Secondary rust removal,lifting machine, bevel machine

5. Power spraying equipment

6. Extrusion machine.

2. rolling mills for produce diameter 8-32mm rebar

3. cooling bed, hydraulic cutting machine

technical team and service team. Sincerely looking forward to your visit our factory .

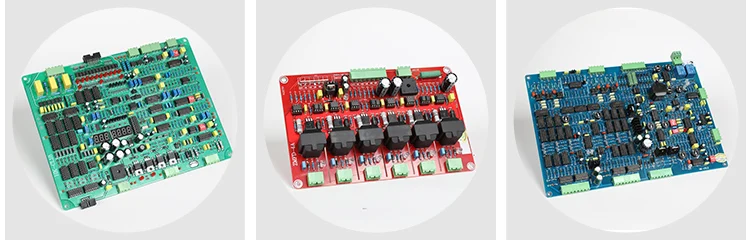

Electric board

The main control circuit board is the core component of the machine.high quality. We have many stocks.

Main control circuit board as the main part of the machine, we made in their research and development, and adopted by the company and built since the automatic welding and testing equipment to ensure that each set of machine can achieve the best effect, and we have main control board in stock lone time, can satisfy the parts supply problems.

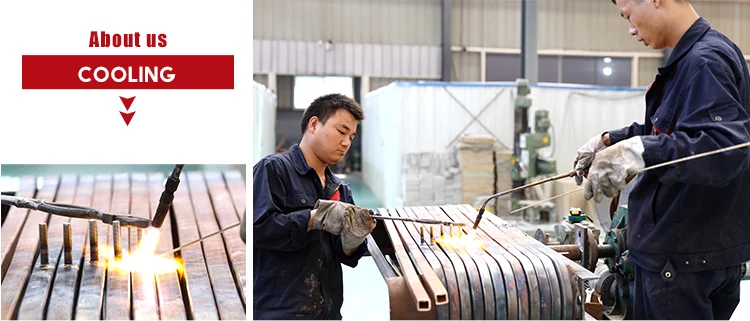

Induction coils

The induction coil inside the furnace body is treated with two insulations. The first spray of high temperature insulation paint. The second round of glass fiber tape. The service life of the treated furnace lining and induction coil will increase by more than two times.

Drawings

technical drawings of automaic tilting induction melting furnace .

meeting

learning training product knowledge

plastic film winding the machine

plywood wooden cases ,standard export wooden cases

We are direct manufacturer specialized in produce in machinery for 15 years.Our factory located in high industry zone,Luoyang

city,henan province,where is the biggest industry machinery manufacturing base in china.

2: Why should we choose Hongteng?How do you ensure the quality?

We have professional research staff and strict in Production,inspection and debugging and package process.We always insist on

supply good pre-sales,order following,after sell service for our customers.

We have professional QC person inspect machinery production.After production finished,all machines will be testing & debugging

carefully before shipment.

3: Which kind of power supply do you supply? Electricity or gas?

Electricity.

4: How can I trust your company and machine?

Our factory have been in producing machinery for around 15 years ,our machine have exported to East Asia, South Asia, the middle

East Asia, Africa etc. areas and have a good feedback with no complaints.

Welcome to visit us,and have a face to face negotiation.

5: How do you control the quality?

We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take

photos and shoot video for you if you need.

6: Which county do you exported to ?

We have already exported our machines to many famous company in many countries, such as

Vietnam,Indonesia,Myanmar,Qatar,Iran,Ukraine etc . Welcome customers to visit our factory.

7: How about your after sales service?

After customers get machines,We will send our engineers to customer's workshop.We will supply installation & debugging & training

service for customers till machine normal production.