1 кг паяльный Наполнитель из никеля паста металлического сплава

- Категории: Сварочные флюсы >>>

- Поставщик: Yantai,Tibright,Welding,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

1kg Nickel Brazing Filler Metal Alloy Paste BNi2

BNi2 Nickel Brazing Paste, Weight: 1kg, BNi82CrSiB

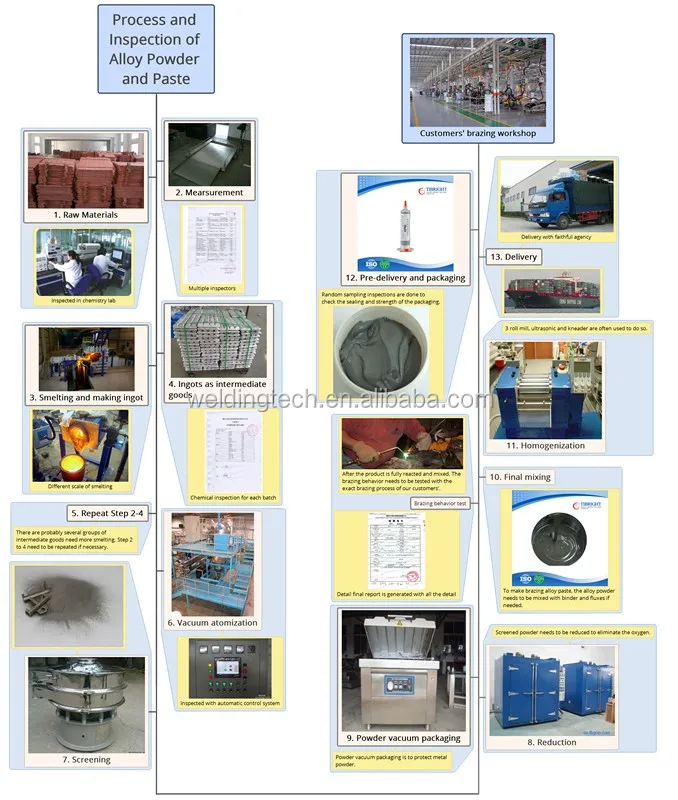

Brazing alloy paste is a brazing material consists of brazing alloy powder with binders mixed carrier. The alloy powder has a complete spherical shape, uniform particle size and low oxygen content. The mixture of well formulated Binder and the powder is a uniform and stable paste without lodgment and caking. It can provide high efficiency, low waste, and automotive application for the brazing process. In addition, brazing alloy paste can be customized with the particle size, viscosity, strength, and drying life.

There are four main kinds of brazing alloy paste according to different utilities, namely, silver brazing alloy paste,copper brazing alloy paste,aluminum brazing alloy paste and nickel brazing alloy paste.

Nickel brazing filler metal paste is widely used to braze diamond and carbide with steel, stainless steel for tools. In car industry, nickel brazing filler metal paste is used to braze car pipe because of its corrosion resistance. Most nickel brazing filler metal paste is used in vacuum or continuous furnace.

AWS standard | Chinese Standard

| Temperature | Materials |

Form | ||||||

Cr | B | Si | Fe | C | P | Ni | ||||

BNi-1 | BNi74CrSiB | 1065-1205 | 13.0-15.0 | 2.75-3.5 | 4.0-5.0 | 4.0-5.0 | 0.6-0.9 |

0.02

|

Bal.

|

Powder/paste |

BNi-1A | BNi75CrSiB | 1075-1205 | 13.0-15.0 | 2.75-3.5 | 4.0-5.0 | 4.0-5.0 | 0.06 | |||

BNi-2 | BNi82CrSiB | 1010-1175 | 6.0-8.0 | 2.75-3.5 | 4.0-5.0 | 2.5-3.5 | 0.06 | |||

BNi-3 | BNi92SiB | 1010-1175 |

| 2.75-3.5 | 4.0-5.0 | 0.5 | 0.06 | |||

BNi-4 | BNi93SiB | 1010-1175 |

| 1.5-2.2 | 3.0-4.0 | 1.5 | 0.06 | |||

BNi-5 | BNi71CrSi | 1150-1205 | 18.5-19.5 | 0.03 | 9.75-10.5 |

| 0.1 |

| ||

BNi-6 | Ni89P | 927-1093 |

|

|

|

| 0.06 | 10-12 | ||

BNi-7 | BNi76CrP10 | 927-1093 | 13.0-15.0 | 0.02 | 0.10 | 0.2 | 0.06 | 9.7-10.5 | ||

BNi-12 | Ni65Cr25P10 | 980-1095 | 24.0-26.0 | 0.02 | 0.1 | 0.2 | 0.06 | 9.0-11.0 | ||

BNi-152 | Ni63Cr29P4Si | 1050-1121 | 28.0-30.0 |

| 4.0 |

|

| 4.0 | ||

Yantai TiBright Welding Materials Co. Ltd., founded in 2000, is a professional developer and international supplier of inclusive brazing materials, equipment, and consultant. TiBright has hundreds of products for different applications. Customized products are also available for specific purposes.

When choose from our product library, please check out our recommended product list, If you have any questions, please let us know, We will try our best to satisfy your inquiry. Sometimes we need our customers to try different samples to make the perfect decision. Generally, we need to know the following information to choose a right product for you.

1. Materials of your parenting parts (to-be-brazed parts).

2. Heating methods. (eg. flame, induction, vacuum furnace etc. )

3. Atmosphere of application. (eg. room air, protective inert gas, reductive gas, vacuum, etc.)

4. Dimensions of your parts. Photos or graphs are preferred. (Different dimensions require different procedures.)

5. Current solution. (eg. brazing materials, equipment, procedures, etc.)

6. The reasons of searching new solution. (eg. price, strength, applicability, etc.)

7. Industry of your application. (Help us refer to similar examples.)

Yantai TiBright Welding Materials Co. Ltd. was started from a laboratory in 1996 and founded in 2000. The company is the first one who specialized in brazing materials in China. The pioneers of the company started product formulas from very basic research. With hundreds of products, TiBright has become a professional developer and international supplier of inclusive brazing materials, equipment, and consultant.

As we focus on brazing materials, our main products are brazing fluxes, brazing alloys, self fluxing brazing alloys, brazing alloy paste, and brazing tools. We make brazing alloys with main components of silver, copper, aluminum, nickel, chromium, zinc, tin, manganese, etc. We also make fluxes and binder agents for these alloys.

Since 2010, our research team has been focusing on the brazing alloy powder and paste as well as the self-fluxing alloys, such as flux coated wires and rings, flux cored wires and rings.

In the year 2015, TiBright was asked to be the first draftsman of the industry standard of China "JB 6045-2015, Fluxes for Brazing" and attended the drafting work of many standards as expertise. TiBright’s research team members apply for patents and publish research articles on academia periodicals every year. By 2016, TiBright has been authorized 15 patents.

Our main current customers are in dozens of different industries, such as radiator, compressor, air conditioner, refrigerator, electric, eye glasses, auto parts, cutting tools, kitchen and bathing, medical instruments, nuclear station, and so on. Our famous customers include Haier, Gree, Media, Siemens, Sanhua, and so on.