TC-HS100E3 LT-HS100E2 машина для рекуперации потока и подачи сварочного манипулятора/дуговая Сварка

- Категории: Other Machinery & Industrial Equipment >>>

- Поставщик: Tang,Cheng,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Application

This is an integrated equipment for flux recovery and pressure feeding. It is applicable for welding manipulator and all kinds of saw equipments used in nuclear power, wind power, boiler, pipe and other cylinders welding projects.

It adopts high quality fans to make recovery; it connects with external compressed air source (0.6Mpa) to feed. Low level alarm reminds worker to add flux when less than 15kg. Pulse dust removal device linked with high-density filter to separate and collect dust from reclaimed flux. Flux replace valve under the machine makes flux replacement simple and fast. Optional heating system can be used for high requirement projects. The automatic flux recovery, flux transmit and flux feed is controlled by the SCM or PLC, each function can be controlled by remote control. The effective flux recovery rate is of 98%, can work inside of 300mm cylinder.

TECHNICAL PARAMETERS | |||||||

Model | LT-HS100E2-50 | LT-HS100E2-100 | LT-HS100E2H-50 | LT-HS100E2H-100 | |||

Input voltage | 380V/50Hz 415V/50Hz 220v/60Hz | ||||||

Motor power | 3kW | ||||||

Air source pressure | 0.4-0.6Mpa | ||||||

Flux capacity | 50kg | 100kg | 50kg | 100kg | |||

Heating temperature | / | 0-150℃ adjustable | |||||

Horizontal recovery distance | 10-15m | ||||||

Vertical recovery distance | 5-7m | ||||||

Volume of flux recovery | 8-15kg/min | ||||||

Volume of flux feeding | 2-20kg/min | ||||||

Horizontal feed distance | 8-25m | ||||||

Net weight | 165kg | 200kg | 195kg | 230kg | |||

Dimension | 1150x550x1450 mm | 1250x650x1600 mm | 1150x550x1450 mm | 1250x650x1600 mm | |||

Goods Supply Range

Main machine x 1pc

LT-EP10 hopper x 1pc

LT-FN38 nozzle x1pc

LT-FNB1 nozzle bracket x1pc

Φ38Hose x4m

Φ25Hose x4m

Heating 0-150℃ optional

Warning parts

•Filter

•Hopper filter

•Recovery hose

•Feed hose

•Flux nozzle

GUARANTEES

One year total guarantee for the supplied machine with the exclusion of wearing parts.

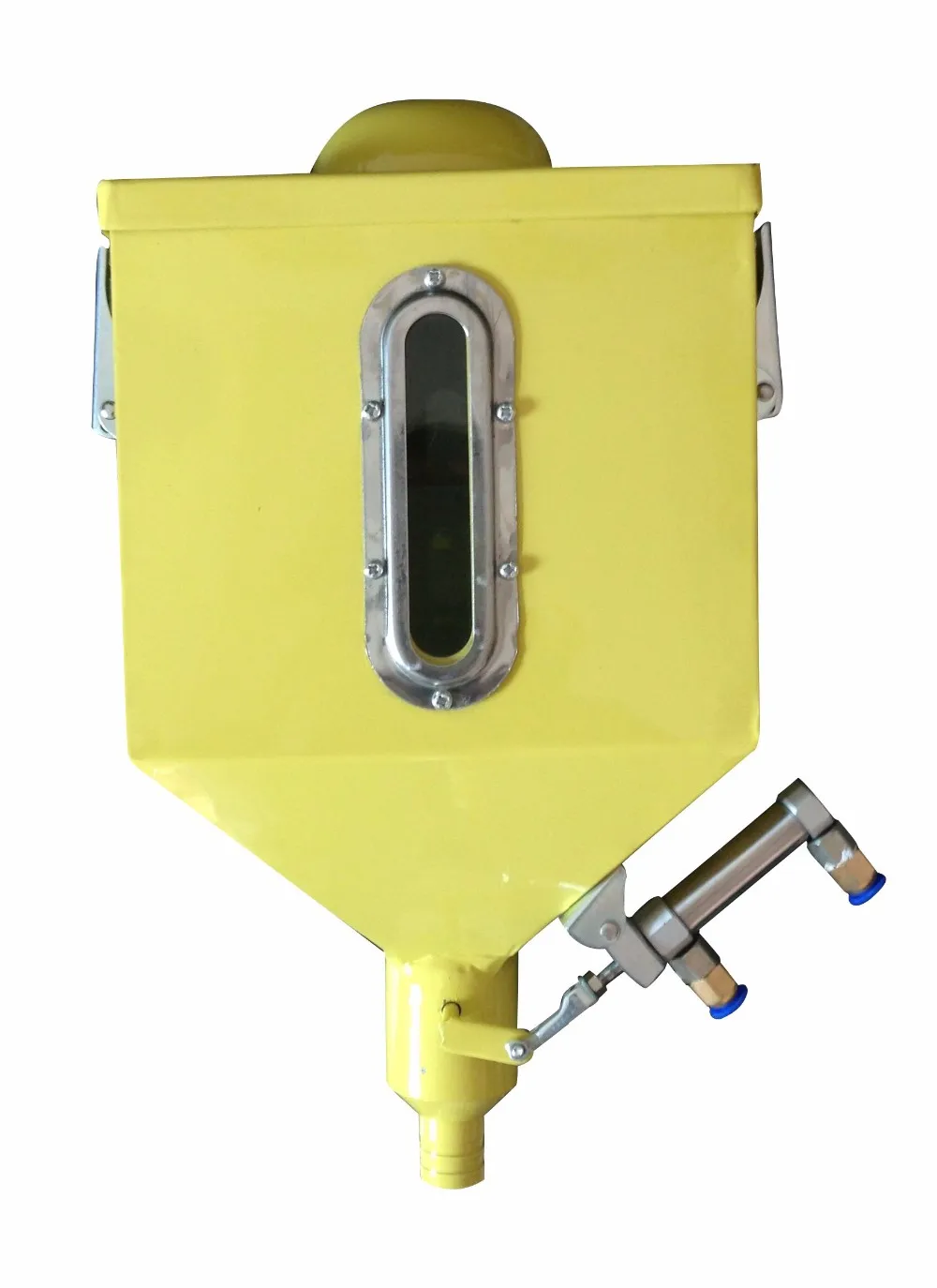

Flux hopper EP10 (standard)

Capacity 5L

Size: 0.3x0.2x0.35m

Flux hopper EP03 (optional for small cylinder inner welding )

Capacity 2L

Size: 0.3x0.2x0.35m

Nozzle bracket FN1 (standard)

Universal nozzle bracket FN2 (optional)