Высокоскоростной штамповочный станок для плоского верхнего

- Категории: Other Machinery & Industry Equipment >>>

- Поставщик: Wuxi,Wondery,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Fin StampingMachine

The aluminium fin stamping machine is used to produce the straight fin with height 9.5mm.

The fin machine is also called as fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.

SPECIFICATIONS FOR aluminium fin stamping machine |

Aluminum strip thickness: 0.01inch; Max effective fin width : 310mm; Raw material: 3003 Aluminum alloy strip coil; H14; Power supply: 3Phase, 380V, 50Hz; The equipment is set with safety signs. Control loop current: 24V DC; Equipment power: 4.0KW; Mold replacement time: < 1 hour for skilled workers; Acceptance standard: CPK: ≧1.67; Mold closing height: 136mm; Working speed: max 80SPM; Fin punch life: 2million ; All documents are both in Chinese and English language. |

Technical Parameters of Aluminium Fin Stamping Machine | ||||||

Control system power | 4.0kw | |||||

Power supply | 3P;380V±10%;50Hz±2% | |||||

Air source | Compressed air 0.5-0.8Mpa; flow rate: 0.00004m3/min; | |||||

Machine accuracy | Levelness of highest point of lower mold table | mm | ≤0.03 | |||

Levelness of lowest point of lower mold table | mm | ≤0.03 | ||||

Levelness of mold table at ascent | mm | ≤0.03 | ||||

Levelness of mold table at descent | mm | ≤0.03 | ||||

Fin specification | Fin (height*pitch) | mm | 9.5mm , 11FPI | |||

Max effective fin width | mm | 300mm | ||||

Max fin height | mm | 12mm | ||||

Aluminum foil width | mm | 310mm | ||||

Machine speed | Inverter control | SPM | 80 | |||

Max cutting speed | Inverter control | Times/min | 60 | |||

Stamping machine dimension | L*W*H | mm | 1500*900*1750 | |||

Noise | db(A) | 80 | ||||

Weight | kg | 2000 | ||||

Main Features

Main Features

The aluminium fin stamping machine is specially used to produce punch fins.

1 .The column bushing of aluminum fin forming machine is made of high-strength imported wear resistant material. It has a service life of more than 1 million times.

2 .The slide of the die of the aluminium fins press machine is of rolling ball structure which has less wear and tear and a longer service life.

3 .The tension control device of the aluminium fins press machine can keep the feeding speed matching with the cutting speed.

4 .The touch screen of the aluminium fin making machine allows the operator to set the parameters directly.

5 .The decoiler is an auxiliary equipment to the fin punching machine. It is equipped with proximity switch and control delay switch so as to control the decoiling speed.

6. The fin press machine is already installed with one set of die for producing fin of one specific specification.

The aluminium fin making machine is also called as aluminium fins press machine, fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.

The fin machine is also called as fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.

Header Mold Information of aluminium fin stamping machine |

Thickness 0.01inch; Fin Pitch : 11FPI; Fin Height:0.374 inch; Fin Width:300mm; Material: punch made of Powder high speed steel FT15; mold seat made of 45# steel; punch plate made of Cr12; |

Decoiler

The automatic decoiler of the aluminium fin stamping machine is an important part of the aluminum fin press machine. It can start or stop decoiling automatically. The fin machine is also called as fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.

Aluminum Fin Press

The aluminium fin stamping machine is used to produce flat fins for heat exchangers by the mechanical pressing force.

The fin machine is also called as fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.

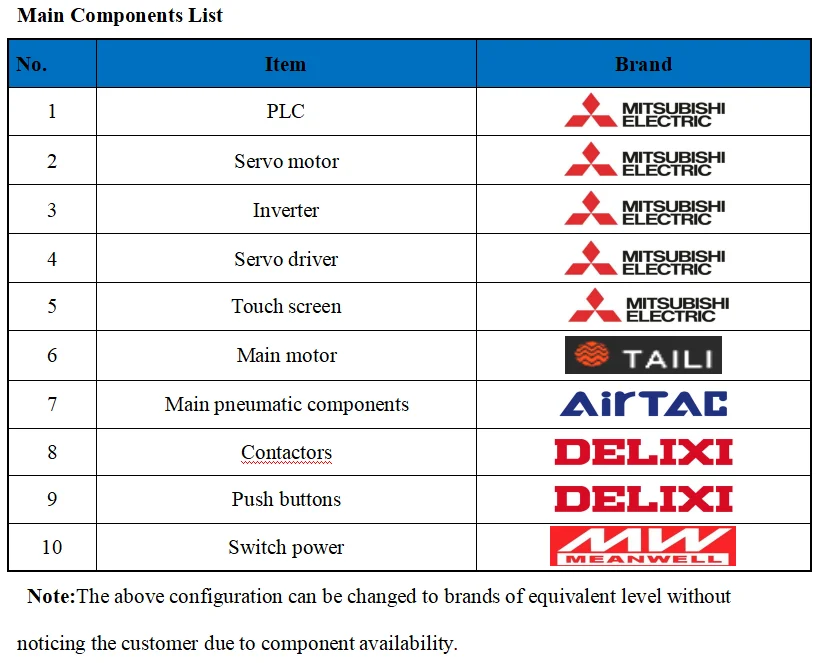

Electrical control system

The control system of the aluminium fin stamping machine employs the famous brand components such as Schneider, Siemens, Omron, Delixi, etc. The aluminium fin making machine adopts the advanced PLC and touch screen combined control. The fin machine is also called as fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.

Servo cutter

The fin machine is also called as fin stamping machine, fin punching machine, aluminum fin machine, fin press machine, radiator fin machine, fin forming machine, aluminum fin press machine, aluminum fin making machine.