Высококачественный горизонтальный фрезерный станок с ЧПУ высокоскоростной

- Категории: Machine Centre >>>

- Поставщик: Anhui,Chizhou,Household,Machine,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

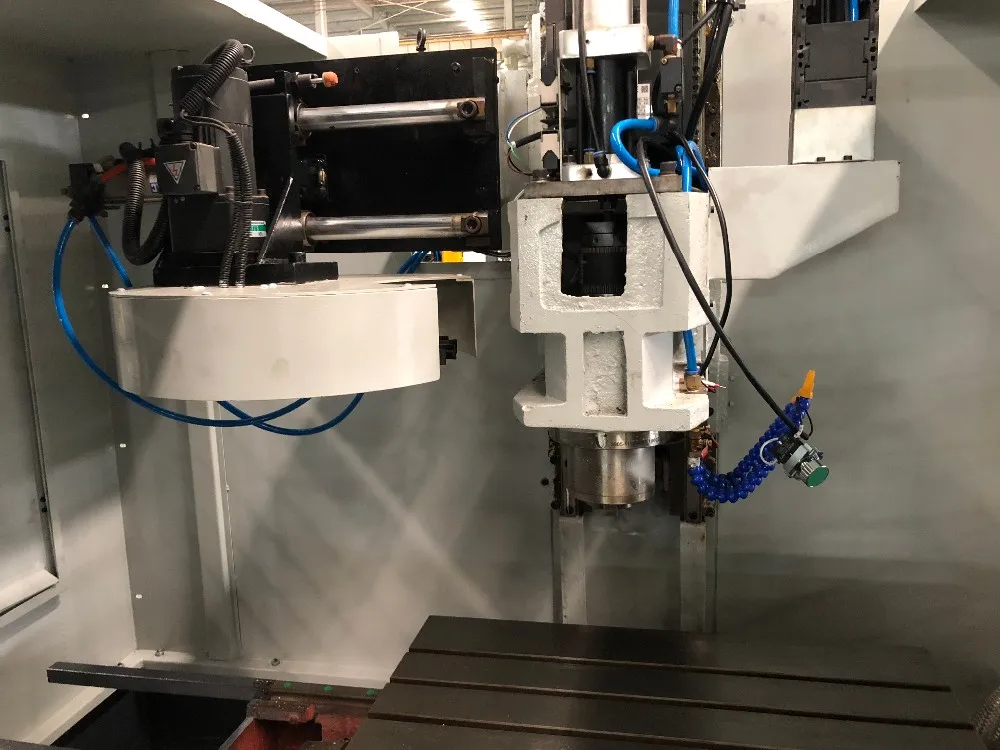

Vertical Machine Center CNC Machine with Linear way VMC500L

Description | VMC750L | |

WORKTABLE | Talbe size | 800*450 |

T slot (width *No.*space)(mm) | 18*3*150 | |

Max.loading weight | 600 | |

TRAVEL | X/Y/Z axis travel | 750/450/500 |

Distance between spindle nose to worktable | 150-700 | |

Distance from spinble center to column | 510mm | |

SPINDLE | Motor power | 5.5/7.5kw |

Spindle speed | 60-8000rpm | |

Spindle taper | BT40 | |

Spindle bearing | P4 | |

FEEDING | X/Y axis fast moving speed (m/min ) | 30 |

Z aixs fast moving speed (m/min) | 24 | |

Linear guideway (X/Y/Z) | 45/45/45 | |

Cutting feeding rate | 1-10000 | |

Min.set and moving unit (mm) | 0.001 | |

Pitch of X/Y axis | 12 | |

Pitch of Z axis | 12 | |

3 axis ACCURACY | Position accuracy | ±0.005 |

Repeated position accuracy | ±0.003 | |

ATC | ATC type | CLOCK ATC/Manipulator |

ATC capacity | 24 | |

Max.diameter of tool (near)*weight *length | Φ80×7*300 | |

Time of tool automatic changing (near)(s) | 3s | |

OTHERS | Weight | 5500 |

Packing dimension | 2600*2300*2500 |

Main Features

1)Use strong rigid casting steel. X/Y/Z axes are supplied with rectangular guide ways by plastic sticker, medium frequency quenching and precisely scraping.

2)Spindle from Taiwan with high speed and precision.

3)Imported bearing with high precision

4)Coolant system equipped with pump of large flow and high lift pump to insure enough cooling under high-speed cutting.

Standard accessories

Arm-type ATC

Automatic lubricating system

Spindle blowing device

Guide-way telescopic cover

Movable hand-wheel

Hand-held air -gun

Alarm light

Coolant system

Working light

RS232 interface

Level adjusting screws and block

Tool-box and manual

Packaging | ||

Size | 2600*2300*2500 | |

Weight | N.W./G.W. 5300/5500KGS | |

Packaging Details | Iron casting pallet with | |

OEM APPROVED

* LOGO OEM accept.

* Packing design OEM accept

* Even machine design OEM accept.

Our team Service

* Professional team,perfect pre-sale and after-sale service.

* Engineers available to service machinery overseas.

* Good English speakers from sale department,can handle your suggestion