Серводвигатель плоский Топ волновой алюминиевый радиатор плавник машина с функцией

- Категории: Other Refrigeration & Heat Exchange Equipment >>>

- Поставщик: Wuxi,Wondery,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

The Servo Type Flat Top Wave Flat Fin Machine with hemming function \t is used to produce heat exchange wavy fins without louver.

The Servo Type Flat Top Wave Flat Fin Machine is equipped with the following devices: decoiler, tensioning device, feeding, interval oil lubrication, fin forming, correction and cutting function, strip run-out detection, blockage detection device, cutting fault indicator, fin forming unit overloading protection device, and fault indication light.

The fin making machine adopts PLC, inverter, AC servo control, and touch screen control. The parameters are easily set through the touch screen.

Technical Parameters of Servo Type Flat Top Wave Flat Fin Machine |

Fin width: 100mm; Fin height: 8±0.05mm; Fin pitch : 3±0.1 mm; Copper strip thickness β: 0.08 mm; Fin shape: Flat Top; Fin R curve: 0.8 ; Copper strip material: 4343/3003/4343 H16 The red informations by customer request Fin tooling blade material: cobalt-containing high speed steel forged parts; Fin tooling blade service life: ≥250 million fin convolutions for pure Copper strip |

Technical Parameters of Servo Type Flat Top Wave Flat Fin Machine |

Aluminum strip coil size: inner diameter: φ200±20 mm (adjustable); outer diameter: ≤1500mm; Fin forming capacity: feeding speed: 0-100m/min; 1000-4000 fin convolutions per minute; stepless regulation by inverter control; Cutting capacity: max 60 times/ min Protection measure: organic glass protection cover over the main machine body; Cutting accuracy: servo control; ±0 fin; cut at the crest; Power supply: 3-phase, 480V, 50Hz Total power: 4.5KW Air source requirement: air pressure >0.4Mp, Q>0.1m3/ min, dry and cool compressed air; Equipment weight: -2500Kg Equipment overall size: 4000X900X1800 |

Configuration For Servo Type Flat Top Wave Flat Fin Machine | ||||

NO | ITEM | BRAND | ||

1 | Inverter | Delta, Taiwan | ||

2 | PLC | Delta, Taiwan | ||

3 | Servo motor | Delta, Taiwan | ||

4 | Servo magnifier | Delta, Taiwan | ||

5 | Pneumatic components | AIRTAC,Taiwan | ||

Introduction to each unit

2. Decoiler: The coil tray supports the coil and it can tighten or loosen the tray by adjusting the tray claw. The changing resistance value of the potentiometer automatically controls the resistance force of the magnetic powder brake. When there is an emergency, the decoiler can be stopped immediately.

3. Feeding resistance adjustment structure: the radiator flat fin machine is set with an automatic feeding system. The damper controller controls the resistance force of the magnetic powder brake to keep the coil feeding speed matching the feeding speed of the fin forming unit.

4. Feeding tensile force adjustment mechanism: consisting of strip run-out detection mechanism, bracket, and pneumatic cylinder. The fin height can be micro-adjusted by changing the working pressure of the cylinder. The strip run-out detection mechanism could cut the power supply of the whole machine when the Aluminum strip runs out.

Edge Folding Device.

The radiator flat fin machine is designed with the edge folding device so as to fold the two ends of the strip on the length direction to increase the strength of the fin. There are two separate folding devices for different fin widths.

Fin Lubrication Device: microspray system.

Our micro-spray precision lubrication device has a daily volatile oil consumption of 4 liters while the traditional intermittent mist spray system has a daily consumption of 10 liters. The lubrication device can provide an even oil film layer to the aluminum strip and ensure sufficient lubrication for the fin forming unit. In this way, the blade life can be assured and the volatile consumption is reduced.

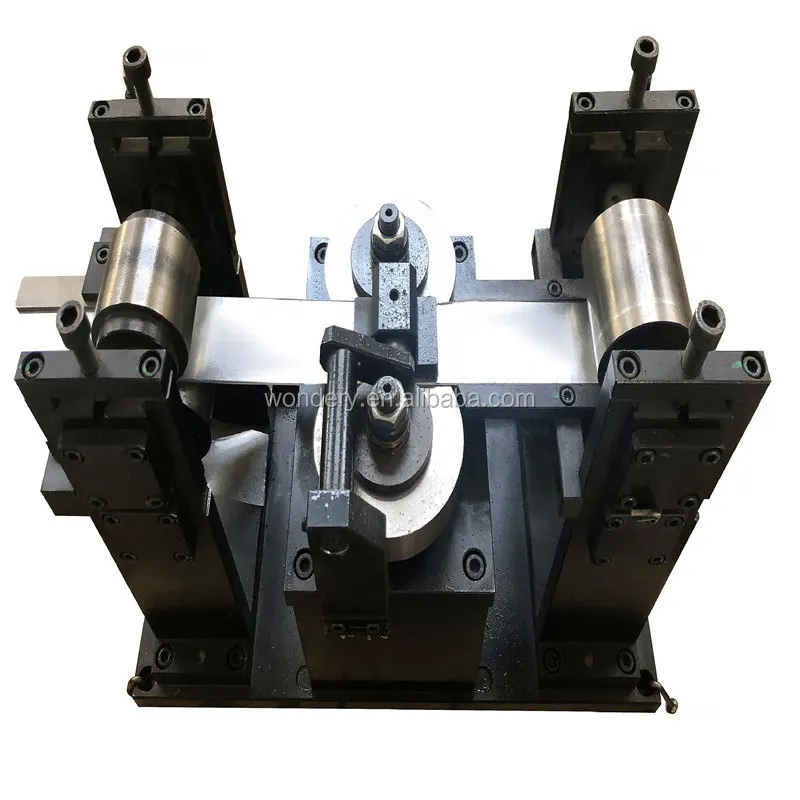

Fin Rolling Machine.

Our factory has its own machining centers, and CNC mills. The fin forming roller and its blades are all made by our own, which makes our machine cost more competitive in the market.

The fin forming roller is changeable, and different fin models can be produced on the same machine.