Пескошайба-высокая эффективность экологически чистый и длительный срок службы! Экономьте деньги с нашей

- Категории: Промыватель песка >>>

- Поставщик: Shanghai,Jianye,Heavy,Industry,Co.,Ltd.Shanghai,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Wheel sand washing machine

The efficient sand washing machine of LSX series is a kind of cleaning equipment of international advanced level for sand and slag pellets, developed on the basis of introducing foreign outstanding technology of the same kind of products.

Sand washer is used to remove the dust in sand. It aims at improving the quality of sand. The materials include the required gravel in building-site, gravel factories, hydropower station and concrete dam site, post and electric pole factory, casting-70 sand, glass factory's quartz sand and refilling pressure sand. It is widely used for cleaning materials in the following industries: quarry, minerals, building materials, transportation, chemical industry, water conservancy and hydropower, cement mixture station and so on.

Sand washer is used to remove the dust in sand. It aims at improving the quality of sand. The materials include the required gravel in building-site, gravel factories, hydropower station and concrete dam site, post and electric pole factory, casting-70 sand, glass factory's quartz sand and refilling pressure sand. It is widely used for cleaning materials in the following industries: quarry, minerals, building materials, transportation, chemical industry, water conservancy and hydropower, cement mixture station and so on.

Product Paramenters

Feeding size: <10mm

Capacity: 20-350t/h

Application field: Sand washing machine is a necessary equipment in wet sand production line to remove stone

Capacity: 20-350t/h

Application field: Sand washing machine is a necessary equipment in wet sand production line to remove stone

powder and soil from machine-made sand. It is suitable for sand units such as gravel plant,

construction site, hydropower dam, etc.

Scope of application: All kinds of rocks can be used for sand making, including pebble, limestone, granite, basalt,

Scope of application: All kinds of rocks can be used for sand making, including pebble, limestone, granite, basalt,

diabase, tuff, andesite, quartz sandstone, conglomerate and other rocks and minerals.

Wide range of fields of use

Working principle

When a XSD Sand Washer is working, driven by the motor, the impeller starts to rotate slowly under the coordinated action of triangular belt, reducer and gear. Sands and gravels enter the wash trough along with the feed trough where they, under the action of impeller, roll over and grind each other to remove impurities on the surface and to destroy the water vapor layer covering sands to facilitate dehydration. At the same time, add water to form a strong water flow to rinse away impurities and foreign matters. Clean sands and gravels are taken away by blades of the impeller and then poured into the discharge trough from the rotating impeller. This is the whole process of sand washing.

Equipment advantage

1. It is of simple structure. The bearing device of impeller drive is separated from water and materials with water, to avoid

in a large degree that the bearings are damaged by being soaked with water, sand or some polluted things.

2. When it is used for cleaning sand in quarries, it has many advantages compared with the traditional spiral one.

3.There is little loss for medium-sized and fine sand and stone powder. The grade and the fineness of the sand for construction after being washed can be up to the national standards, such as "sand for construction" and "cobble and broken stones for construction".

in a large degree that the bearings are damaged by being soaked with water, sand or some polluted things.

2. When it is used for cleaning sand in quarries, it has many advantages compared with the traditional spiral one.

3.There is little loss for medium-sized and fine sand and stone powder. The grade and the fineness of the sand for construction after being washed can be up to the national standards, such as "sand for construction" and "cobble and broken stones for construction".

4. There are no other wearing parts except the screen mesh.5.It features long service life and few times for maintenance.

Product packaging

Model | Impellerspecifications | Impellerrotory speed | Capacity | Feeding size | Waterconsumption | Motor power |

XSD2610 | φ2600*1000 | 1.178 | 20-50 | ≤10 | 20-60 | 5.5 |

XSD2816 | φ2800*1600 | 1.177 | 30-60 | ≤10 | 50-100 | 11 |

XSD3016 | φ3000*1600 | 1.179 | 50-120 | ≤10 | 70-120 | 15 |

XSD3620 | φ3600*2000 | 1.180 | 80-150 | ≤10 | 80-140 | 18.5 |

Wrapping and delivery

customer site

Our machine has been sold to Germany, Australia, Japan, Mexico, Philippines, Indonesia, Russia, Uganda, Uzbekistan, Poland, etc. and our products are well received by customers.

All machine has a 1-year quality assurance. As long as the machine has any problem (non-human factors) within one year, we will repair or change with new one for free. Please rest assured to buy and use!

Video introduction

Shanghai Jianye Heavy Industry Co., Ltd. is an international mining machinery supplier which is integrating manufacturing, R & D and sales. Its products include crushing and sand making equipment, industrial grinder mill, screening and washing equipment, mobile crushing plant etc. These equipment are mainly used in sand and stone aggregate processing, mining, construction waste recycling, industrial powder making, etc.

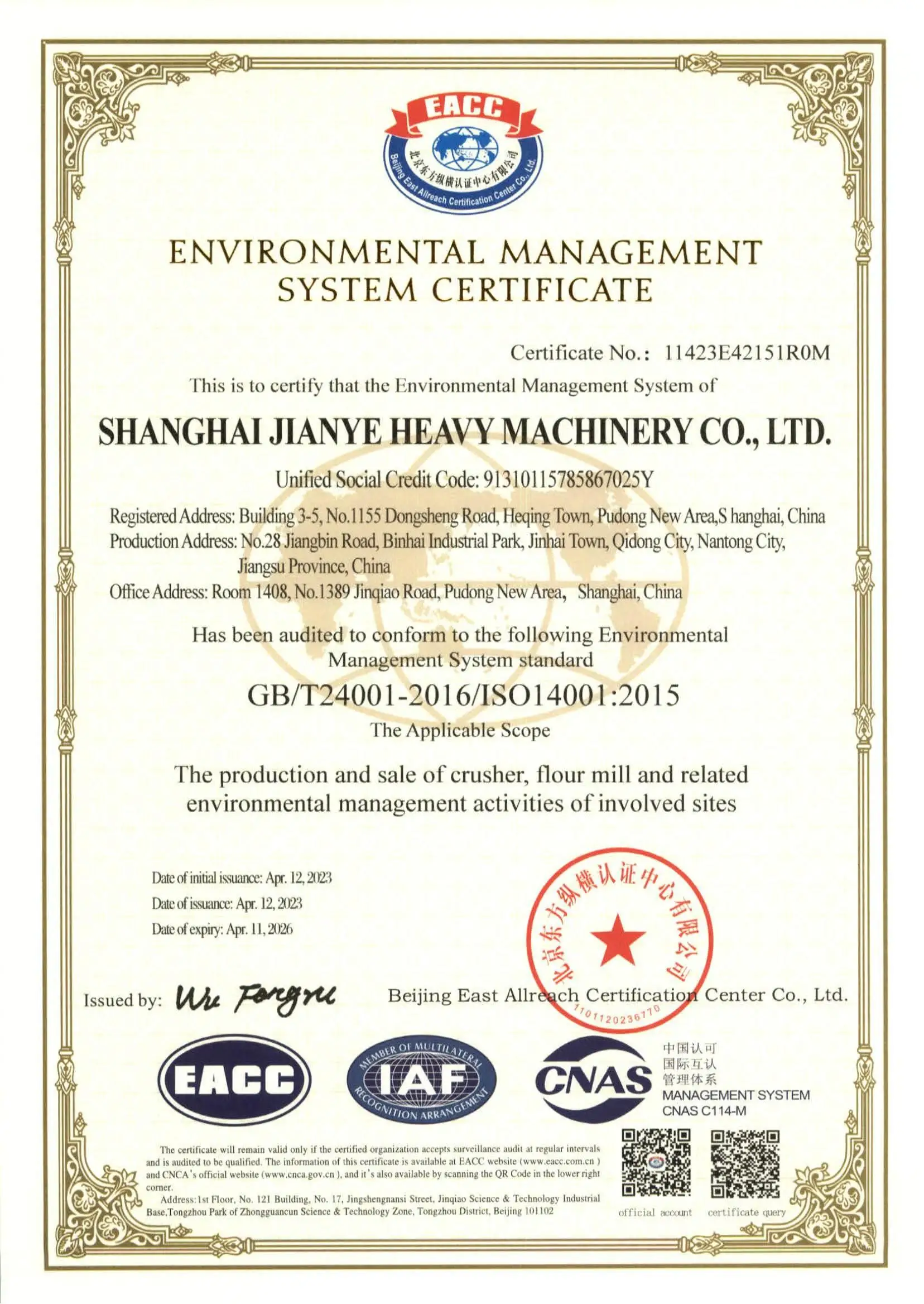

Product certification certificate

Our own factory

AFTER-SALES SERVICE AND CONCEPT

PRODUCTION LINE PROFILE

Our Company Has Reliable Products And Experienced Service Team. 1et The Internet Techinology Apply To Every Tache Of Pro-Duct Andoperation. Sale By Internate Actively, Provide The Atest Product Information And Technical Service. We Believyou-Not Only Need a Product, Butalso Good After Service. Based On The Techinology And Quality Products,We Would Provide The Gratfed, Save Worry, Disburden Service For Ouicustomers.PRE-SALE

1.Guide Our Customers To Deploy The Most Useful Equipment Item According To Theirs Requiryment.

2.Provide Technical Date,Including Equipment Bill, Layout, Base Specification And Installation Picture To Consult,

3.Design And Manufacture Product According To The Customers'Special Requestment.

4.Dispatch The Technical Person To Reach The Locale To Layout Field, Design The Best Installtion Flow And Scheme To Consult For Free.

3.Design And Manufacture Product According To The Customers'Special Requestment.

4.Dispatch The Technical Person To Reach The Locale To Layout Field, Design The Best Installtion Flow And Scheme To Consult For Free.

SALE

1 Product According To The Standard Of Technology Strictly. 2.Experiment The Machine By The Operating Regulate,

3.Verify The Product Before Leaving Factory Strictly, 4.Organize Shipping By The Contract In Time.

3.Verify The Product Before Leaving Factory Strictly, 4.Organize Shipping By The Contract In Time.

AFTER-SALES

1 Dispatch Special Worker After Service To Arrive Locale To Guide The User To Install And Debug, Experiment Circulate, Train Operating Persons For Free.

2. Guarantee Of Repair, Replacement And Refund Of Substandard Products, The Period Of Guarantee Is 1 Year(Except Abrasion In Normal, Wearing Parts, The Damaged Parts By Misoperation) If The Equipment Appears Fault During Guarantee, Our Company Woulde To Reach The Locale After Take The User's Telephone, Remove The Fault, Ensure The User's Produce Innormal.

Want more product information or product prices?

Похожие товары

Лучшее качество Xsd машина для очистки песка

US $1590-$9985

Винтовая пружинная шайба для продажи

US $8000-$9500

Небольшая Мобильная пескомойка 2XL915, пескомойка

US $10000-$40000