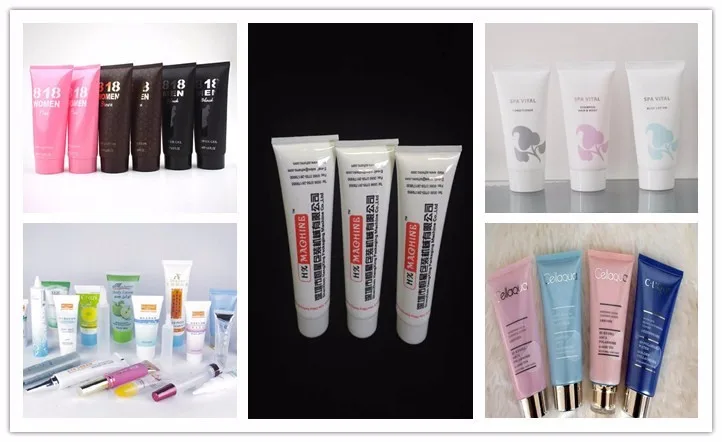

Модный стиль 200 мл Корея двойной тип Косметическая трубка для волос

- Категории: Косметические тюбики >>>

- Поставщик: Shenzhen,Hengxing,Packaging,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Function:

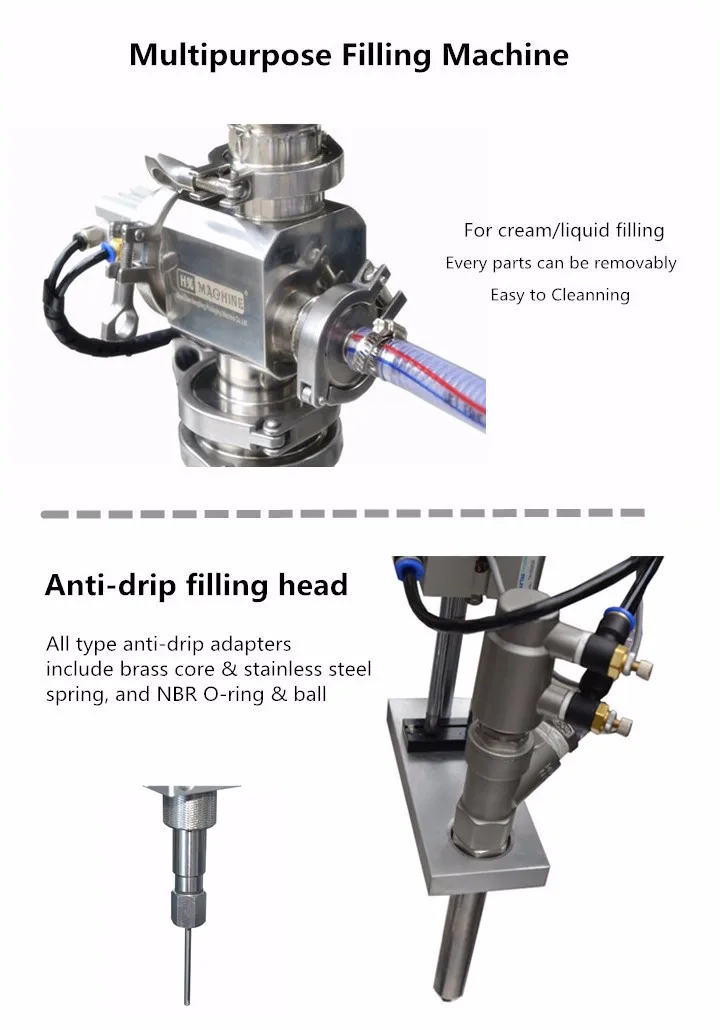

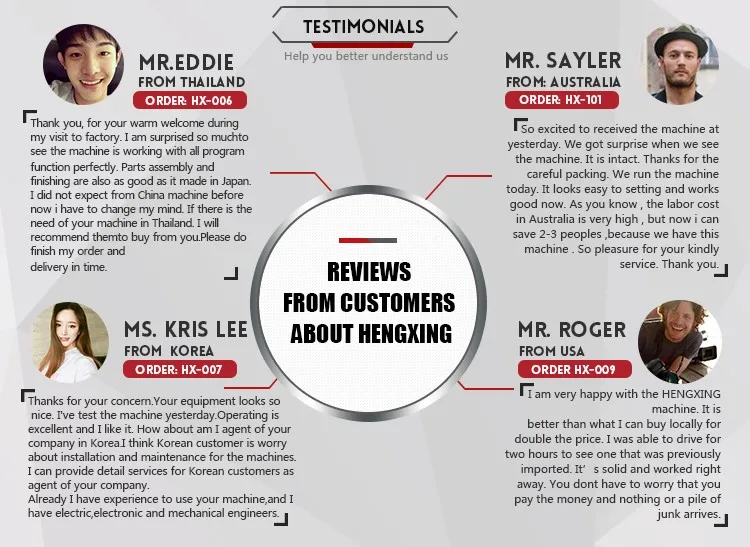

1.This machine applies the transmission principle. It uses the slot wheel dividing system to drive the turntable to do intermittent movement.

2.The machine has 10 sits. Expect manually putting the tubes on the machine, it can automatically fill the material into the tubes, heat both inside and outside of the tubes, seal the tubes, press the codes, and cut the tails and exit the finished tubes.

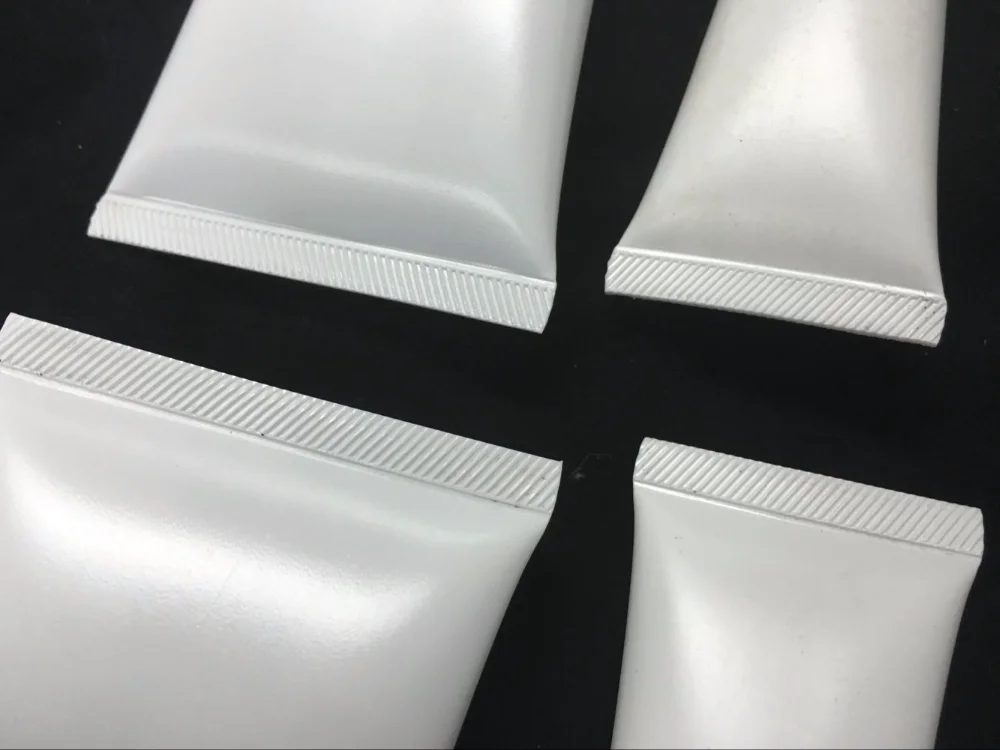

3.Filling measurement is accurate. Heating time is stable and adjustable. Sealed tail looks pretty and neat and the trimming is very even.

4.This machine has stable performance and work without any noise and pollution.

Features:

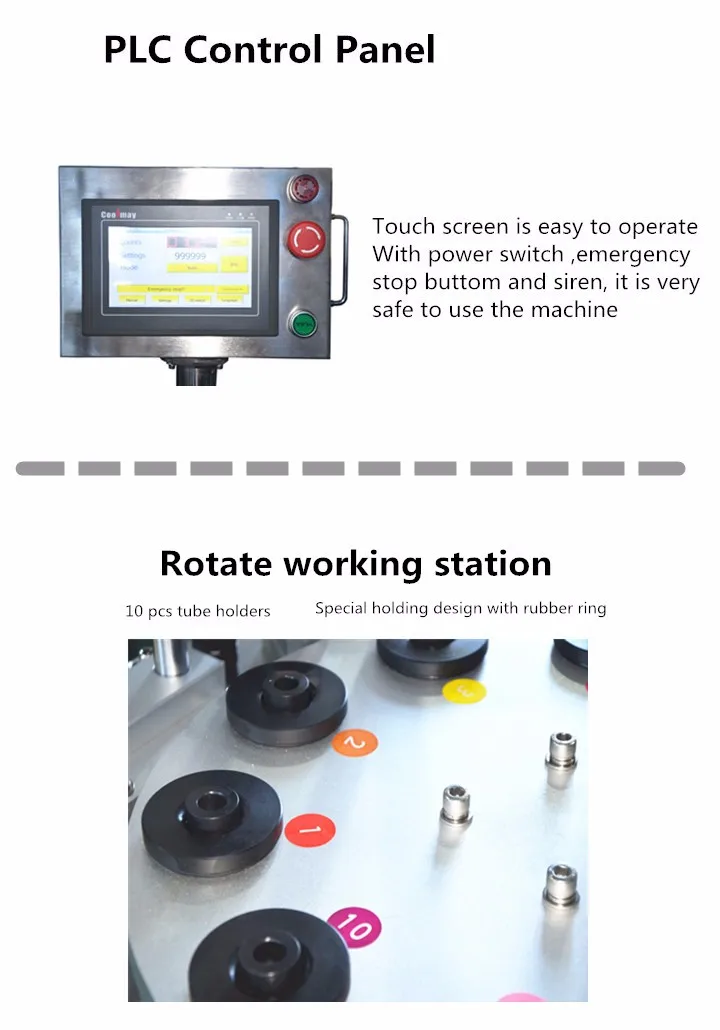

1.Mitsubishi PLC contact

2.Auto orienation

3.AUTO filling and sealing

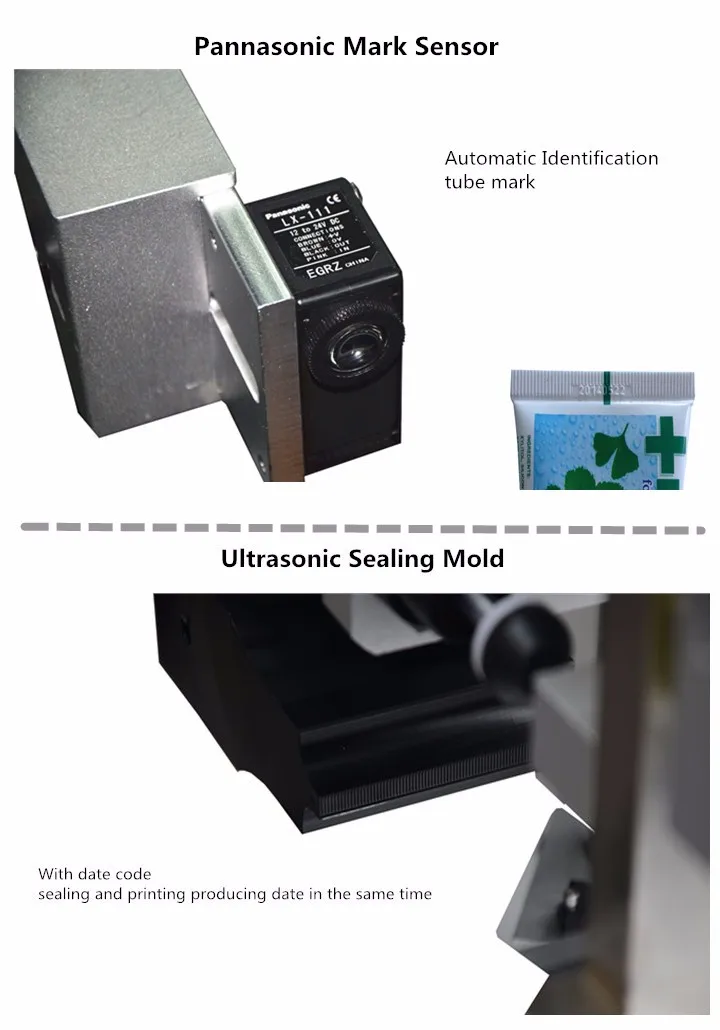

4.Auto date printing

5. Digital ultrasonic system (automatic fit frequnecy )

6.more satble and strong ourput power

7.20-30tubes/min

SPECIFICATIONS FOR AUTOMATIC TUBE FILLING SEALING MACHINE | ||||||

Model Number | HX-009 | |||||

Power supply | AC220V /110V 50/60HZ singe phase | |||||

Power | 2KW | |||||

Filling Range | A:5-30ml B: 6-60ml C: 10-120ml D: 25-250ml E: 50-500ml | |||||

Filling Accuracy | ±1% | |||||

Sealing Dia. | 5-50mm | |||||

Max.height | 10-250mm | |||||

Capacity | 16-30tubes/min | |||||

Air supply | 0.6-0.8Mpa, 0.35m²/min | |||||

Hopper | 30L (Customer-made available) | |||||

HS code | 8422 303090 | |||||

Dimension | 1300*1540*1600mm, 450kg | |||||

Machine Body | 304# stainless steel | |||||

ultrasonic tube sealing machine for stripes tubes

91.8% Response Rate

ultrasonic tube sealer

91.8% Response Rate

semi -auto Tube filler and sealer

91.8% Response Rate