Крепежные детали нержавеющей стали поворотной шаровой кран из конец пол фланец прокладка

- Категории: Gaskets >>>

- Поставщик: Dongguan,Jingcheng,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Name | Stainless steel flanges stub end stainless steel floor flange stainless steel gasket flange |

Service | OEM,ODM and Standard |

Material | 1.Steel:303/304/316/412/etc 2.Aluminum alloy:5052/6063/2017/7075/etc 3.Brass alloy:3602/2604/H59/H62/etc 4.Steel alloy : carbon steel/ die steel/etc 5.Other special materials :copper /bronze/iron/etc 6.ABS, PA, PC, PC/ABS, PP, PPS,PPO, POM, PMMA, PE, HDPE, TPE/R etc |

Surface | 1.White / yellow / black Zinc plated , nickel / chrome / aluminum alloy plated 2.Polishing , Electroplate , Baking finish , Oxidation,anodize,passive,powder coating. |

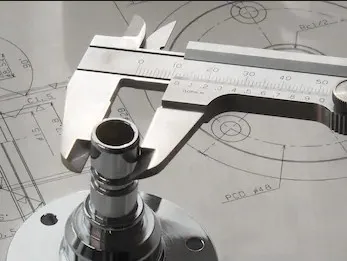

Operation | CNC machine , Lathe machine , Milling machine , Drilling machine , Planning , Grinding , Boring , Wire-electrode cutting ,and tapping |

Advantage | 1,Professional precision manufacturer for more than 15 years.1. Quality control : We have experienced QC team that you can rely on.The defective products rate is 0.1%. 2. We have reasonable price with precision made. 3. Each part would be given 100% test and tryout before shipment. 4.Best after sales service is provided. |

Delivery term | EXW, FOB, CIF,DDU,DDP |

Application | Bearings, cams, handles, plumbing components, rollers, rotors, slide guides, valves, knobs, lenses, housings, panels, trays, toys, frames, bushings, covers, seals, sheilds, caps, electrical insulation, housewares, medical tubing, washers |

Main category

Sheet metal processing (machine equipment shell, enclosure , chassis ,Cabinet , Frame , Box ,Plate ,Grille , Holder , Support, craft gift, metal interior decoration), Precision CNC machining parts, Metal Lath parts ,BMS testing equipment, vending machines..

Quality and delivery

WE HAVE QA,OQC,IPQC for quality control system . They ensure the quality of shipment while efficient production. Every batch of products will be inspected before shipment, so as to ensure the high-quality goods to customers . At present, the customer's satisfaction with us is as high as 98%.

Professional engineering team

Engineering team have more than 10 years expressive on functional ,Structural and appearance design, process improvement .There are 8 people ,who have discussing and participating in the design and development of OEM many times , And signed the confidentiality agreement with the customer, 100% protect the customer's rights and interests.

Sheet metal fabrication is the process of forming a piece of metal into a desired shape through bending, stretching, and removal of material. At Rapid, we use press brake punches and die tooling to bend and stretch flat stock into its final geometry. The sheet metal prototyping process is most often used when form, fit, and function are all a priority.

Typical sheet metal parts we manufacture include enclosures, brackets, assemblies, weldments, cabinets, and other components. Whether you need a single sheet metal part or 20 parts, we have the capacity to produce your sheet metal prototypes fast.

PROTOTYPE SHEET METAL SERVICE DETAILS

1-50+ Parts

Shipped in as fast as 5 days

Minimum flat part size 0.5 in. x 0.5 in.

Minimum formed part size 1.5 in x 1.5 in.

Max. flat part size of 48 in. x 40 in.

Copper max. part size of 48 in. x 36 in.

Typical sheet metal parts we manufacture in production quantities include enclosures, brackets, weldments, and other components.

PRODUCTION SHEET METAL SERVICE DETAILS

50-500+ Parts

Shipped in as fast as 10 days

Max. flat part size of 40 in. x 48 in.

We handle in a careful and economic way for ocean shipping, like paper box,pallet,or carton. Package size and

container loading quantity are calculated by engineers based on products size in order to work out a best solution.

Every piece is fixed by protective foam,plastic tape,batten etc. to protect products from shipping damage.

To conclude:

1. Custom plywood crate or box for heavy sheet metal parts.

2. Heavy duty carton for small and lighter metal parts.

3. Bubble bag or protective film for inner protection to avoid scratches.

4. Plywood pallet is available when sheet metal products are in large amount.

5. Shipping marks as per request.