Трубчатый испаритель MVR для химической

- Категории: Испаритель >>>

- Поставщик: Nanjing,Gaojie,Light,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Working principle and features:

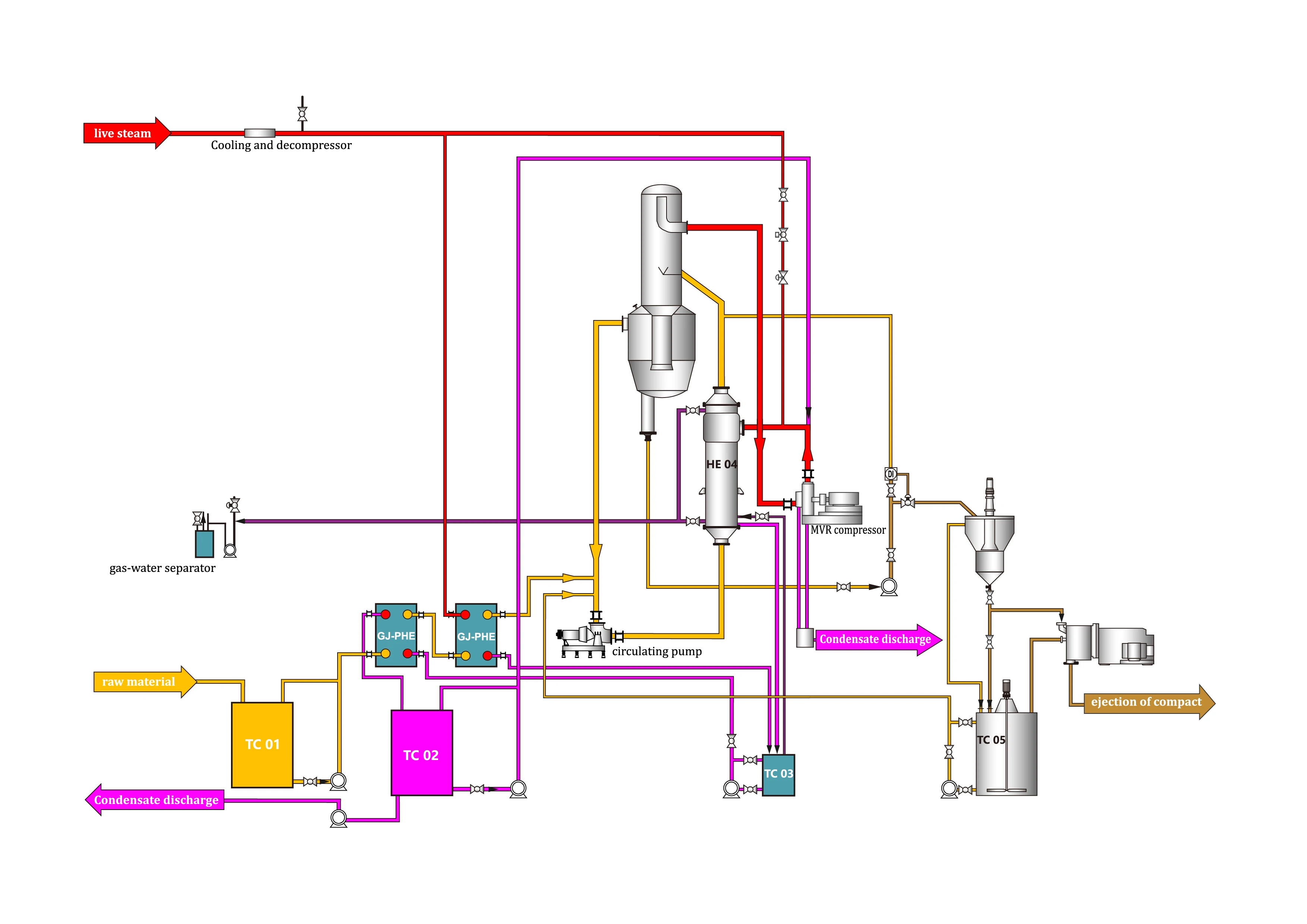

The MVR forced circulation evaporation system consists of the main equipment of the evaporator, separator and forced circulation pump, and steam compressor. The material exchanges heat with the steam outside the tube in the tube of the evaporator, and the temperature rises; the solution after the temperature rise is divided into two phases of steam and solution, and the steam rises to the separator, and the demister separates the liquid entrained in the steam. The droplets are purified and sent to the compressor. The compressor compresses the steam and transports it to the evaporator shell for heating steam to realize secondary steam recycling and continuous evaporation. Evaporation produces secondary steam overflowing from the material, the material is concentrated into supersaturated material, crystallized, and the crystal slurry is output from the circulation pipeline by the discharge pump; the mother liquor enters the forced circulation pump, enters the evaporator under the action of the circulation pump, and then evaporates. This cycle is continuously evaporated to concentrate and crystallize. It has the following advantages: 1. Suitable for materials with high viscosity, 2. Materials with particles; 3. High concentration ratio; 4. High flow rate of pipeline, not easy to dry wall or scale.

The commonly used types are as follows:

Why Choose us?

1. More than 20 years of experience in the design and manufacture of evaporation systems, which can quickly determine the problems of the evaporation system during operation, and has a data database of practical operations of hundreds of materials.

2. The professional personnel and R&D team of the evaporation department have the most complete plate evaporation type in China, which is satisfied with the process needs of different industries.

3. Product series, rising film, lifting film, and falling film three series of evaporators, gathered in all the advantages of evaporation form, respectively, in different empirical data, is the most advanced and complete professional company in the field of evaporation.

4. The evaporation plate type has the largest single-plate area of the international model and the smallest model to meet different working conditions.

5. Semi-welded imported plate evaporator plate type, leading international technology, to solve the problem of expensive imported equipment and untimely service.

6. Ranked first in the market share of plate evaporation system in the starch sugar industry. China's first brand in the refined sugar market at home and abroad, has rich experience in overseas projects, and has served the project experience of evaporation systems for many countries.

7. The design process is compact and the system energy saving effect is more significant than similar products. And each system has 3D drawings.

Nanjing Gaojie Light Industry Equipment Co., Ltd. is a professional manufacturer specializing in heat exchangers, condensers, multi-effect evaporation concentrating devices and evaporation crystallization equipment, which is a national high-tech enterprise. It integrates design, production and sales.

FAQ

Q : 1. Can I have a sample ?

A : Yes, welcome to place sample order to test and check quality.Mixed samples are also OK.

Q : 2. What is your the lead time for production?

A : Generally Sample needs 1-3 days,mass production needs 15-30 days,also depands on your request.

Q : 3. Can you accept mixed batch of different products?

A : Yes,we can provide different product mix wholesale.

Q : 4. what payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q : 5. what is the warranty for your products?

A :We provide one year warranty for the products..

Q : 6. Are you trading company or manufacturer?

A :Yes,We are manufacturer.Welcome to visit our factory and check our pruducts.

If you have any other questions,Please feel free to contact us!