Машина для производства гранулятора из кукурузного крахмала биоразлагаемых пластиковых

- Категории: Оборудование для обработки пластика и резины >>>

- Поставщик: Nanjing,Tengda,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Background introduction:

This kind of machine is used to produce biodegradable material, like PLA+PBAT+etc.; PE+Corn starch......

Because the government in many countries like India, Tunisia etc. begins to conduct environment protection policy, the market of the biodegradable material is quite hot now. This is a kind of Eco-friendly material.

After being used for 3-6 months, the biodegradable material can be completely degraded into carbon dioxide and water without polluting the environment.

The bio-based materials industry has the advantages of environmental protection, energy conservation and emission reduction, and renewable raw materials. It can not only solve the white pollution problem fundamentally, but also reduce oil consumption and ease the pressure on petrochemical resources.

Applications:

Corn Starch Biodegradable Plastic Pellet Making Machine Recycling Granulator Machine:

The main uses of biodegradable materials are: disposable tableware, non-woven fabrics, packaging materials, agricultural coatings, toys, coatings, glues, fibers and other biodegradable products.

Main parameters:

These parameters of Corn Starch Biodegradable Plastic Pellet Making Machine Recycling Granulator Machine are for reference only, please contact me for additional instructions if you have other needs.

MODEL | SCREW DIAMETR | CENTRAL DISTANCE | MOTOR POWER | OUTPUT |

TSH20P | 22MM | 18MM | 3/4(KW) | 2-15 KG/H |

TSH30P | 26.1MM | 26.1MM | 7.5/11/15(KW) | 10-55 KG/H |

TSH35P | 35.6MM | 30MM | 11/15/22(KW) | 10-95 KG/H |

TSH40P | 41MM | 34.5MM | 22/30/37(KW) | 40-150 KG/H |

TSH52P | 51.4MM | 43MM | 45/55/75(KW) | 120-350 KG/H |

TSH65P | 62.4MM | 52MM | 75/90/110(KW) | 200-550 KG/H |

TSH75P | 71MM | 60MM | 110/132/160(KW) | 300-850 KG/H |

TSH85P | 81MM | 67.8MM | 200/220/280(KW) | 600-1400KG/H |

TSH95P | 93MM | 78MM | 250/315/450(KW) | 750-2250KG/H |

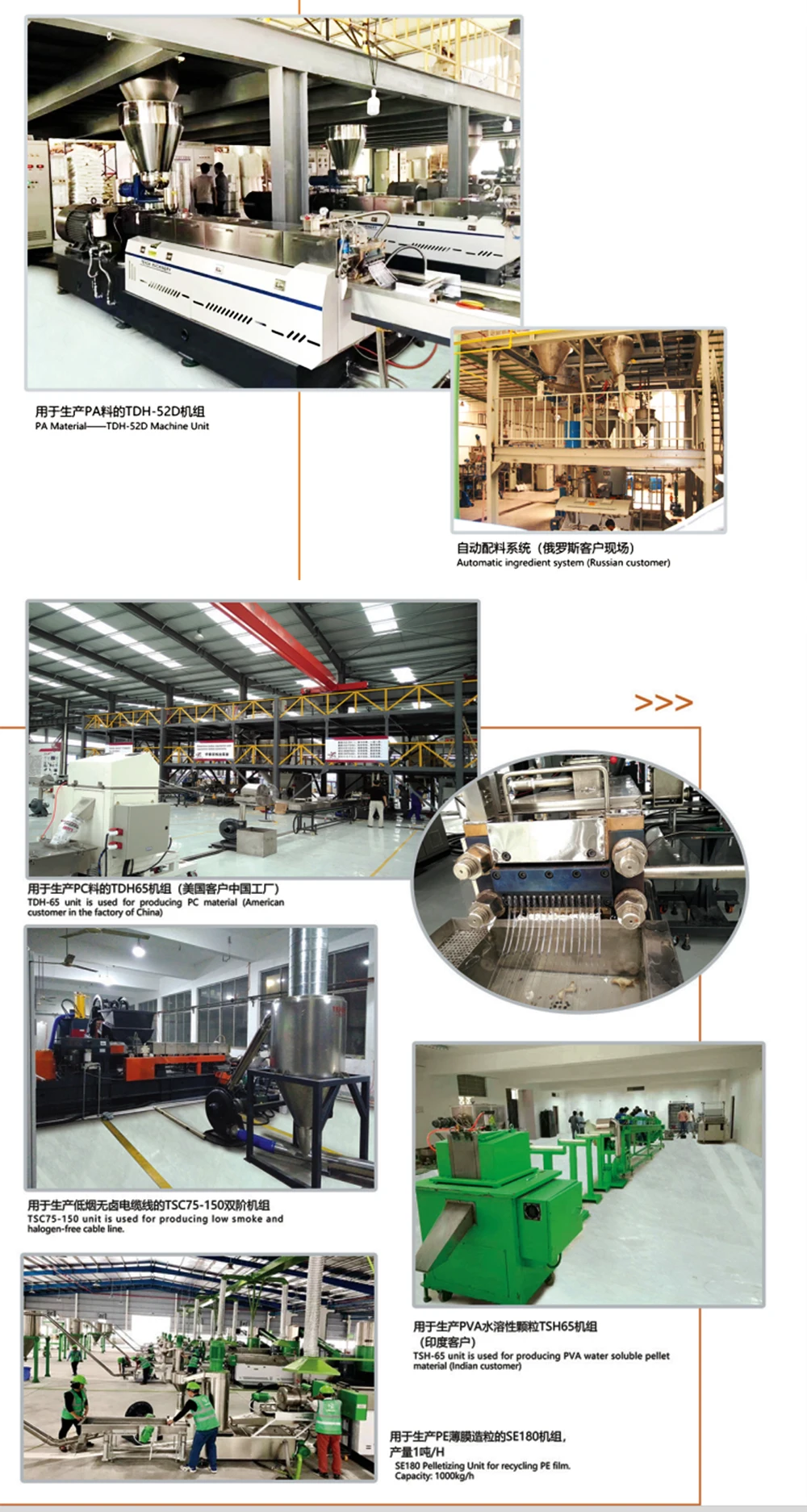

Production Process:

Corn Starch Biodegradable Plastic Pellet Making Machine Recycling Granulator Machine:

This is the compounding and pelletizing system, some formula need high speed mixer or high and low speed mixer. Contact us, we will help you customize the machine configuration.

Certification authority:

Certifications of Corn Starch Biodegradable Plastic Pellet Making Machine Recycling Granulator Machine:

1. Established in 2009; Over ten years experience to produce twin screw extruder compounding and pelletizing system;

2. High-tech and rich experience in almost formula of material; we can help you on business;

3. Exported to many countries all over the world;

4. We focus on manufacturing high-end extrusion machine. Since its inception for ten years, our company has been known for good reliability, won the trust of new and old customers, and insisted on creating the greatest value to customers. "Tengda Machinery" will create excellent quality plastic machines, and be dedicated to serving you forever;

5. Enterprise Mission: Let every user of our machine use the peace of mind, rest assured, worries, create a win-win model, and continue to develop for at least 192 years,three centuries, the same dream!

6. Enterprise Version: Constantly surpass, committed to become an internationally competitive national enterprise. Let the plastic granules produced by Tengda Machinery extensively applied in every corner of the world, let Tengda become a production source that is indispensable for people's life;

7. Business philosophy: Quality-oriented, Remain true to our original aspiration and keep our mission firmly in mind.

1.Energy-saving:

All main motors of machine use Variable Frequency Motor(AC), eliminating three-phase asynchronous motors;

Variable Frequency Motor:

(1) Speed regulation is easy and energy saving.

(2) AC motor has simple structure, small volume, small inertia, low cost, easy maintenance and durability.

(3) It can expand output and achieve high speed and high voltage operation.

(4) Soft start and fast brake can be achieved.

(5) No spark, explosion-proof, and strong environmental adaptability.

2.High output:

Take "PP" material as an example, the PP material is tested on the customer's site, our machines' actual production output is 10%-20% higher than the same model in the market;

3.Simple installation:

The equipment is easy to install, only need to be connected to the inlet and outlet water, which can save 2 days of installation time;

4.Advanced design:

All electrical components are imported famous brands, like German "SIEMENS", France "SCHNEIDER", United States "CEME", Japan "ORMON" "TOSHIBA" "FUJI" etc.;

The industry's first advanced dust cover design, beautiful appearance and simple maintenance;

Use a thicker and more heat-resistant heater to ensure the heating effect of the barrel and the service life of the heater;

The water cooling system of the barrel adopts stainless steel pipes and valves;

5.Others:

Available production video reference;

At the discretion, lead customers to visit the customer site;

6.Good after-sales service:

The warranty of main gearbox is extended for free for three years;

Modernized CNC processing equipment to fundamentally guarantee the supply of quantity and quality of equipment spare parts;

We provide engineers overseas installation service.