Графитовая форма по индивидуальному размеру для литья Медного

- Категории: Изделия из графита >>>

- Поставщик: Xinxiang,Benteng,Electrical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

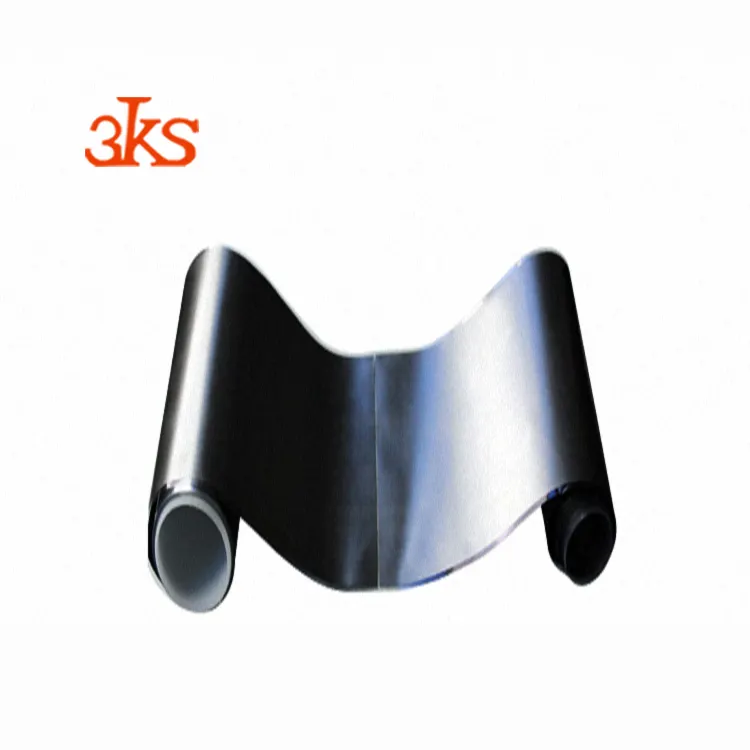

Graphite material has chemical stability, is not easily infiltrated by molten meltal, does not change the composition of it, graphite material has good thermal shock resistance, small size changes with temperature, etc., so it has become an indispensable mold material in metallugy, which can be used to make tubes, elbows, funnels and so on

.

Graphite molds are used for stamping, forging, die casting, extrusion, injection molding or other forming processes.

High-purity graphite mold for metal smelting consists of mold cover, mold cavity, welding cavity, guide groove and mold clamp, which can withstand high temperature melting of copper, steel, iron and other metals.

High-purity graphite mold for metal smelting consists of mold cover, mold cavity, welding cavity, guide groove and mold clamp, which can withstand high temperature melting of copper, steel, iron and other metals.

Product Name | Graphite mold |

Material | High purity graphite |

Certification | ISO9001 |

Standard | Customized |

Used | Stamping, forging, die casting |

Company Web | https://www.bentengcorp.com |

Direction for use

使用说明

Description of application effect

使用效果描述

Get better dimensional accuracy castings at much lower speed than sand casting and investment casting. The mold is not easy to expand and does not warp or corrode, so it can be reused. The easy-to-process graphite mold can be quickly and economically produced. modify.

Detailed Images

The introduction of graphite products into the metallurgical industry is very important, not only can improve the smelting temperature, but also can be smoothly carried out as a metal smelting conductor, and can also be used as a lubricating material to improve the wear resistance of equipment parts, so in today's smelting industry Graphite products cannot be lack of a material.

Related Products

crystalizer inner tube

graphite protective

Insulation sleeve

Packing&Shipping

Delivery Time: within 15 working days.

Terms of shipment: by air, by sea, by railway, express.

Terms of shipment: by air, by sea, by railway, express.

Packing: inner packing: coverd with paper in paper box

outer packing: wooden carton

After Sales Service

After-sales Service

1) Supply the design suggestion and layout plan for the clients workshop.

2) Supply the technical specification of the auxiliary facilities for the cli ents.

3) Supply the equipment operation training.

4) Supply the installation,start-up and commissioning service.

2) Supply the technical specification of the auxiliary facilities for the cli ents.

3) Supply the equipment operation training.

4) Supply the installation,start-up and commissioning service.

Company Introduction

Founded in 2008, Xinxiang Pentium Electric Equipment Co., Ltd. is an experienced copper UP casting CCM manufacturer in mainland China. It has the most advanced copper processing technology enterprise and has integrated R&D, processing, manufacturing, installation and maintenance. Continuously learning the requirements of domestic and foreign counterparts on copper processing equipment and technology, the process and technology of the oxygen-free copper rod/tube/rod-up continuous casting machine has made a major breakthrough. Our copper platoon technology is a leader in the industry. Today, we offer you casting machines with state-of-the-art technology, world-class production lines and ACE services. Customer trust and support is our driving force for continuous improvement and pursuit of dreams. We sincerely hope to cooperate with potential partners to create a better future.

FAQ

Why would we be your choice?

* Professional solution acccording to your and your customer's requirements.

* 11 years copper machine manufacturing experience and state-of-the-art technology with Benteng.

* Never about the maintainace, Benteng offers you mature after-sale services and spare parts.

* Professional solution acccording to your and your customer's requirements.

* 11 years copper machine manufacturing experience and state-of-the-art technology with Benteng.

* Never about the maintainace, Benteng offers you mature after-sale services and spare parts.

Похожие товары

Высокотемпературный графитовый горшок, графитовый тигель

US $1.00-$20.00

Ультратонкая графитовая лента 0,017 мм, электропроводящий лист

US $0.20-$10.00

Квадратная графитовая форма для литья и плавки

US $3.00-$50.00