Термостойкий волновой паяльник 380C

- Категории: Insulation Materials & Elements >>>

- Поставщик: Prior,Plastic,Co.,Limited

Поделиться:

Описание и отзывы

Характеристики

Product Name | Wave solder pallet |

Material | Fiber glass cloth + high temperature resin |

Color | black |

Size | As per drawings |

Thickness | 3mm-30mm |

Certification | ISO9001, SGS, CTI, ROHS |

Application | wave solder pallet, reflow solder pallet, SMT pallet, solder paste printing |

Customized High Precision Wave Solder Pallet As Per Drawings

Tips for machining ricocal material

1. The material of the cutter: carbide such as Tungsten Carbide +Cobalt

2. How many flutes for the cutter ? 4 flutes

3. Feed speed(cutting speed): for 3.175mm cutter, feed speed is 2000mm/min

4. Wall thickness:1mm

- Excellent durability against repetitive soldering of more than 20,000 times.

- Excellent mechanical strength for precision machining.

- Excellent chemical resistance against soluble flux or pallet cleaner.

- Teflon-coating is not necessary to make up for durability or cleanability.

- Excellent machinability which is durable against high speed machining.

- Lead free material/ RoHS COMPLIANT

- Strong Thin Wall up to 0.5mm

Technical Data Sheet | ||||||||

Name | Ricocel material for wave solder pallet | |||||||

Grade | Anti-static | |||||||

Density(g/cm3) | 2.1 | |||||||

Flexural Strength 3 point support⊥(Mpa) | 470 | |||||||

Water Absorption(%) | <0.1 | |||||||

Coefficient of linear Expansion(10-6/k) | 11 | |||||||

Thermal Conductivity (w/m0k) | 0.4 | |||||||

Maximum Operating Temperature(℃) 10-20seconds | 380 | |||||||

Standard Operating Temperature(℃) | 300 | |||||||

Life Cycles(Times) | >20000 | |||||||

Surface Resistivity(Ω) | 10^6-10^9 | |||||||

Thermal Capacity(J/kgk) | 960 | |||||||

Modulus of Elasticity (Mpa) | 20000 | |||||||

Chemical Resistance | Excellent | |||||||

Thickness Available(mm) | 3,4,5,6,8,10,12,15,20,25,30 | |||||||

Thickness Tolerance(mm) | ±0.1 | |||||||

Parallelism(mm) | ±0.1 | |||||||

Sheet Size (mm) | 1020*1220mm, 1220*2440mm | |||||||

Universal pallet

We can fabricate the pallets for our customers as per drawings

Wave solder pallet

The lead time for samples is 5 working days after order confirmation.

Reflow solder pallet

The lead time for bulk order is 7-10 working days.

Factory

Workshop

Warehouse

Warehouse

Packing Details : by cartons or by export pallets

Delivery Details : 3-5 working days after payment received.

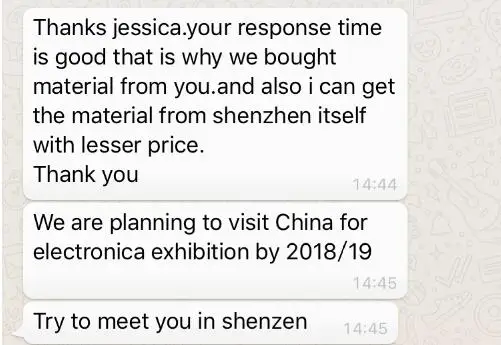

Favorable comment from USA

Thanks Jessica. Your response time is good that is why we bought material from you. And also I can get the material from Shenzhen itself with lesser price.

Favorable comment from India

Favorable comment from Italy

We got a better offer from another Chinese company. But we prefer to buy from you because you seem more professional.

Q: What's your MOQ?

A: For stock items, 1PC qty is also accepted.

Q: What’s your lead time?

A: Generally we can arrange shipment within 3 working days after payment received. For OEM orders, the lead time is 7-10 working days.

Q: Can I get free samples ?

A: Yes, we can offer samples for free by using customers collected courier account. For old customers, we can also bear the shipping cost.

Q: What’s the warranty of your product ?

A: We offer 1 year warranty for our products.

Q: How will you handle customer complaint ?

A: We have four basic steps for customer complaint.

1. We will request customers to provide related pictures or videos for the actual problem.

2. Our after-sales team will study the case, and find out the reason why the quality defects happen.

3. We will have meeting to come up with a proposal, and discuss with customers if they are satisfied with the solution.

4. We will have QC meeting to learn from the case in order to avoid same problems happen again.