С оптимизатором мощная китайская автоматическая двутавровая пила с

- Категории: Деревообрабатывающее оборудование >>>

- Поставщик: Foshan,City,WEHO,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

with optimizer Heavy duty China automatic cnc beam saw machine

1.cnc beam saw works for large amount of precise cutting.

2. Automatic blade reciprocating incising saw can be used for cutting several pieces of wood panel at presupposed width and thickness automaticly and continuously.

3. Work stability to avoid after-sale maintain problem.

4.Having the rigid heavy duty machine frame.

5.High speed saw carriage runs up to 120m/min or 150m/min.

6.CNC panel pusher driven up to 100m/min with AC servo motor.

7.Optimized soft for beam saw machine is included.

8. Back loading with automatic feeding is optional .

Product Name | Heavy duty China automatic cnc beam saw machine |

Model | HP270G |

Cutting length | 2700mm |

Cutting thickness | 0-100mm(120mm optional) |

Main saw blade diameter | 350mm(405mm) |

Main saw spindle diameter | 60mm |

Main saw spindle speed | 3910rpm |

Blade diameter | 180mm |

Auxiliary saw shaft diameter | 45mm |

Side saw spindle speed | 5100rpm |

Sawing seat speed | 5-100m/min |

Sawing seat back speed | 120m/min |

Main saw blade motor | 20HP(25optional) |

Scoring saw Blade motor | 2.2kw/3HP |

Sawing seat drive motor | 1kw |

High pressure blower motor | 3HP |

Automatic feeding system | 2kw(AC sero motor) |

Work holder feeding speed | 5-80m/min |

The use of air pressure | 7kg/cm² |

Work platform height | 1020mm |

Gross weight | 5600KG |

cnc beam saw is updated products in the panel saw industry, with high cutting accuracy and stable cutting.

With furniture development, rapid development of the industry, manufacturers spent huge human and financial resources on cutting plates.

The disadvantages of using the sliding table panel saw in the cutting of plates becomes more and more obvious: insufficient precision, edge collapse, fault, work injury and other phenomena often occur, which brings obvious constraints to development of enterprises

Features of the beam saw machine

1.Environmental protection: dustproof curtain can make the work environment more clean, more accurate sawing.

2.The cutting board workshop dust, reduce the harm to human and environment cleaner production, low noise.

3.Operation is simple, easy to understand: do not need to use skilled workers, a teacher will be, you can save the cost of the material master please.

4. Man-machine integration operation, directly on the touch screen to enter the size of a variety of sizes and then automatically starting.

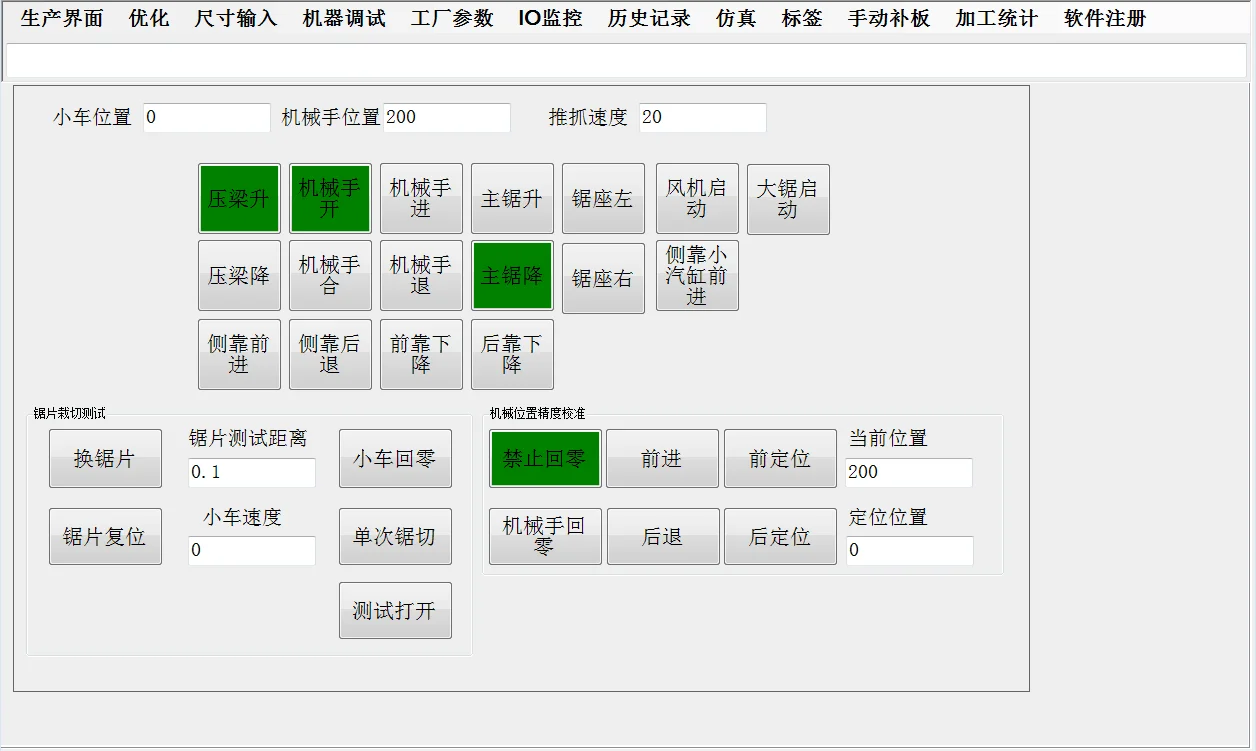

Opitimized Software is Standard configuration

Optional safety protection

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines.

Our goal is to exceed customer expectations. We’re machine factory, but service is our business.

WEHO Machinery is an original equipment manufacturer, all machines can be custom built to the customer requirements. We can design and manufacture most of wood processing machines....

![]()