Производитель симметричных обсадных систем ODEX сверлильные

- Категории: Детали оборудования для горнодобычи >>>

- Поставщик: Xiamen,Leanoms,Science,And,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

World-Class Quality Rock Drilling Tools

As International drilling tools supplier for over 20 years, we've been addressing our customers ' expectation and offering solutions that focus on increasing productivity and stability. Today, in addition to offering a comprehensive range of products, we also help clients optimize drilling solutions. With LEANOMS, you are backed up by a global partner that is committed to providing the better drilling experience for you. Our complete solutions include a wide range of tools and services–aimed at improving your safety, productivity and competitiveness.

Products Description

LEANOMS Overburden Drilling Systems

Symmetrix and Odex – leading casing drilling solutions

In fact, with the development of DTH drilling and the introduction of special drilling systems like Symmetrix and Odex, casing advancing in overburden has become more refined.

LEANOMS Symmetrix/Symmetric overburden drilling systems

LEANOMS Symmetrix/Symmetric overburden drilling systems

Symmetrix is a patented system comprised of an ingeniously simple concentric method of drilling through over- burden with casing.Symmetrix drills straight holes, in any type of ground conditions, at any angle and to depths beyond 100 meters.

The Symmetrix system

The three main components of the system are made up of:

The three main components of the system are made up of:

A casing shoe welded to the casing pipe which is pulled down by the impact of the hammer and pilot bit.

A symmetrical ring bit that is locked onto the pilot bit drills the void for the casing to advance down the hole. There are three different types of ring bit and cas- ing shoe assemblies;

■A solitary ring bit with no connection to the casing shoe.

■A welding ring that holds the ring bit and casing shoe together.

■A factory assembled ring bit set with integrated ring bit and casing shoe.

Permanent or retrievable casings

Permanent or retrievable casings

Pile types in foundation drilling

Foundation piles are generally divided in two different types, end bearing piles and skin friction piles.

End bearing piles

Installing end bearing piles

1.Casing is installed until bedrock

2.Drill string is pulled out from the hole

3.Reinforcement element is installed and concrete poured into the hole

2.Drill string is pulled out from the hole

3.Reinforcement element is installed and concrete poured into the hole

Skin friction piles

Installing skin friction piles

1.Casing is installe.

2.Drill string is pulled out from the hole

3.Reinforcement element is installed and concrete poured in

Finally the casing is pulled out with ring bit set

Finally the casing is pulled out with ring bit set

Common system requirements

Large pass through inner Diameter

System with large pass through inner diameter

1.Casing is installed until bedrock

2.Drill string is pulled out from the hole

3.Drilling of the well continues with a DTH bit,

which passes through the ring bit

which passes through the ring bit

Systems with drill-through pilot bit

System with drill-through pilot bit

1.Casing is installed until surface of bedrock

2.Drill through pilot bit is unlocked from ring bit and after that pilot bit drills a rock socket Drill string is pulled out from the hole

3.Reinforcement element is installed and concrete poured into the hole

Special system designs--Symmetrix features

Each Symmetrix system is made from high quality al- loy steel, and has been precision machined to produce a perfect bit body, heat treated to the required hardness, and fitted with durable tungsten carbide buttons.

LEANOMS ODEX/Eccentric overburden drilling systems

LEANOMS ODEX/Eccentric overburden drilling systems

Product Features And Structure

1.Spare parts surface with hardening treatment

With longer operating life and excellent wear resistance

2.Structural optimization

Simple structure, easy to operate

3.Superior performance

Stable and reliable performance, high drilling speed

The following ODEX dimensions are available for down-the-hole drilling:

ODEX 90 for 3” hammers

ODEX 115 for 3” and 4” hammers

ODEX 140 for 4” and 5” hammers

ODEX 165 for 5” and 6”hammers

ODEX 190 for 6”and 8” hammers

ODEX 240 for 8” hammers

Guide devices are available to fit all common hammer types.

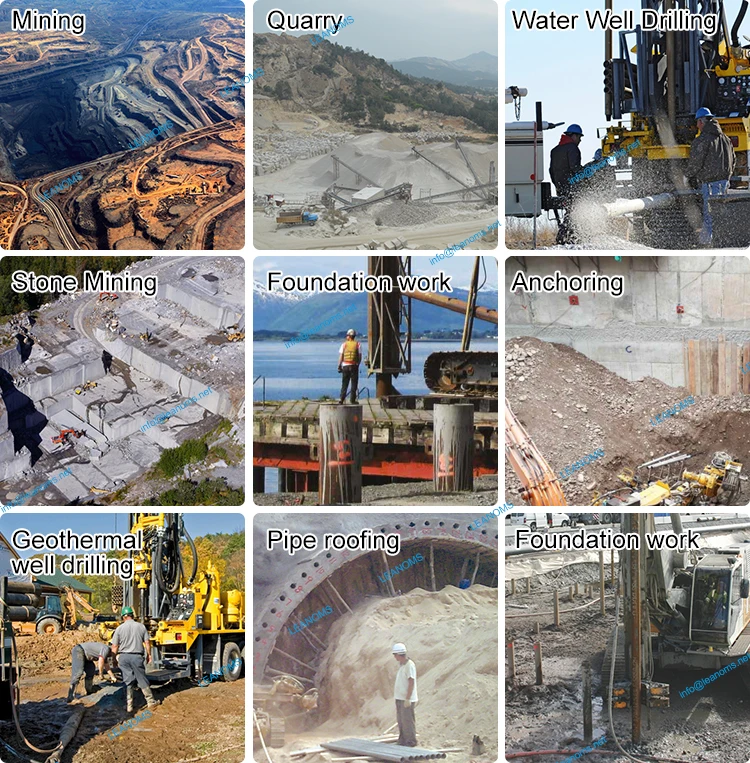

Application

Application

All our products, which passed ISO9001 quality management system, are widely used in open pit mining, tunneling, quarrying,transportation construction,engineering, earth-rock excavation, water wells, pile foundation, and civil engineering project etc.We are one of the companies which have the most complete product lines, the most abundant species and the most widely usedproducts in drilling industry.

Company Profile

Company Profile

LEANOMS is a comprehensive company that integrates the design, manufacture, marketing and technical services of rock drilling tools. The products due to stable quality, excellent performance are being sold well all over China and exported to Europe, America, Middle East, Australia,Africa, Southeast Asia and other regions, more than 50 countries.

LEANOMS products range covers:

1.Down the hole(DTH) hammer and bit,

2.Drill pipe(drill rod)

3.Casing system

4.Tricone bit,PDC bit,Steel tooth bit

5.Top hammer rock drilling tools(thread button bit, drill rod, shank adapter)

6.Small hole drilling tools(tapered button bit, tapered drill rod, plug hole integral drill rod, integral drill rod),and other rock drilling tools that are widely used in mining, tunneling, quarrying, water well, anchoring,transportation construction, pile foundation, and civil engineering projects etc.

By using high-quality raw materials, utilizing advanced craft technologies and imposing strict quality inspection,all LEANOMSproducts quality are controlled under the same high-level. Each of our drilling products is designed for optimum performance in drilling applications on a price vs. performance basis. We offer high quality productive tools and service for all drilling applications.

LEANOMS products range covers:

1.Down the hole(DTH) hammer and bit,

2.Drill pipe(drill rod)

3.Casing system

4.Tricone bit,PDC bit,Steel tooth bit

5.Top hammer rock drilling tools(thread button bit, drill rod, shank adapter)

6.Small hole drilling tools(tapered button bit, tapered drill rod, plug hole integral drill rod, integral drill rod),and other rock drilling tools that are widely used in mining, tunneling, quarrying, water well, anchoring,transportation construction, pile foundation, and civil engineering projects etc.

By using high-quality raw materials, utilizing advanced craft technologies and imposing strict quality inspection,all LEANOMSproducts quality are controlled under the same high-level. Each of our drilling products is designed for optimum performance in drilling applications on a price vs. performance basis. We offer high quality productive tools and service for all drilling applications.

Recommend Products

FAQ

FAQ

1.Q: Are you manufacturer?

A: Yes, We are manufacturer. We have 10 workshops manufacture various drilling products, including DTH hammer and bit, drill pipe,

casing System,tricone bit,top hammer drill rod, drill bit, shank adapter coupling, tapper button bit and rod, integral drill rod

etc. We can supply you

one-stop service that provide full range of rock drilling products.

2.Q: How many workers in you factory? And what is your company scale?

A: Area of our factory: 120,000 square

Numbers of our employees:800 experienced workers

Numbers of our equipment&facilities:over 400sets Advanced high-end equipment

Numbers of DTH Hammer production yearly:over50,000 sets

Numbers of Drill bits production yearly:over 600,000 sets

Annual turnover in USD:500 Millions

3.Q: What quality certificates do you have?

A: ISO9001:2008 quality management system

RoHS

EC examination certificate

4.Q: Where did you export and what was your annual export amount?

A: Over 50 countries,including Europe ,Africa. South America, Mid East and Asia countries etc .

Our average annual export amount within recent 3years is 100million USD.

5.Q: Do you offer warranty on your products?

A: Yes. For different products we offer different warranty that cover all manufacturing defects in materials and workmanship. The

longest

period of warranty is 2 years after shipping date.

6.Q: How long is your delivery time?

A: 1-2days for the products in stock

regular order delivery in 2-3weeks

7.Q: What kind of payment terms do you offer.

A: We offer different payment terms, including T/T, D/A, L/C, Credit Card etc.

Any other questions,please feel free to contact with me online or by phone.

A: Yes, We are manufacturer. We have 10 workshops manufacture various drilling products, including DTH hammer and bit, drill pipe,

casing System,tricone bit,top hammer drill rod, drill bit, shank adapter coupling, tapper button bit and rod, integral drill rod

etc. We can supply you

one-stop service that provide full range of rock drilling products.

2.Q: How many workers in you factory? And what is your company scale?

A: Area of our factory: 120,000 square

Numbers of our employees:800 experienced workers

Numbers of our equipment&facilities:over 400sets Advanced high-end equipment

Numbers of DTH Hammer production yearly:over50,000 sets

Numbers of Drill bits production yearly:over 600,000 sets

Annual turnover in USD:500 Millions

3.Q: What quality certificates do you have?

A: ISO9001:2008 quality management system

RoHS

EC examination certificate

4.Q: Where did you export and what was your annual export amount?

A: Over 50 countries,including Europe ,Africa. South America, Mid East and Asia countries etc .

Our average annual export amount within recent 3years is 100million USD.

5.Q: Do you offer warranty on your products?

A: Yes. For different products we offer different warranty that cover all manufacturing defects in materials and workmanship. The

longest

period of warranty is 2 years after shipping date.

6.Q: How long is your delivery time?

A: 1-2days for the products in stock

regular order delivery in 2-3weeks

7.Q: What kind of payment terms do you offer.

A: We offer different payment terms, including T/T, D/A, L/C, Credit Card etc.

Any other questions,please feel free to contact with me online or by phone.

Contact Us

Похожие товары

Буровое долото из карбида вольфрама 8 1/2 "IADC 537 637 tci tricone

US $200.00-$520.00

Буровая установка поворотного типа

US $100.00-$200.00