Производственная линия блоков aac завод по производству

- Категории: Brick Making Machinery >>>

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

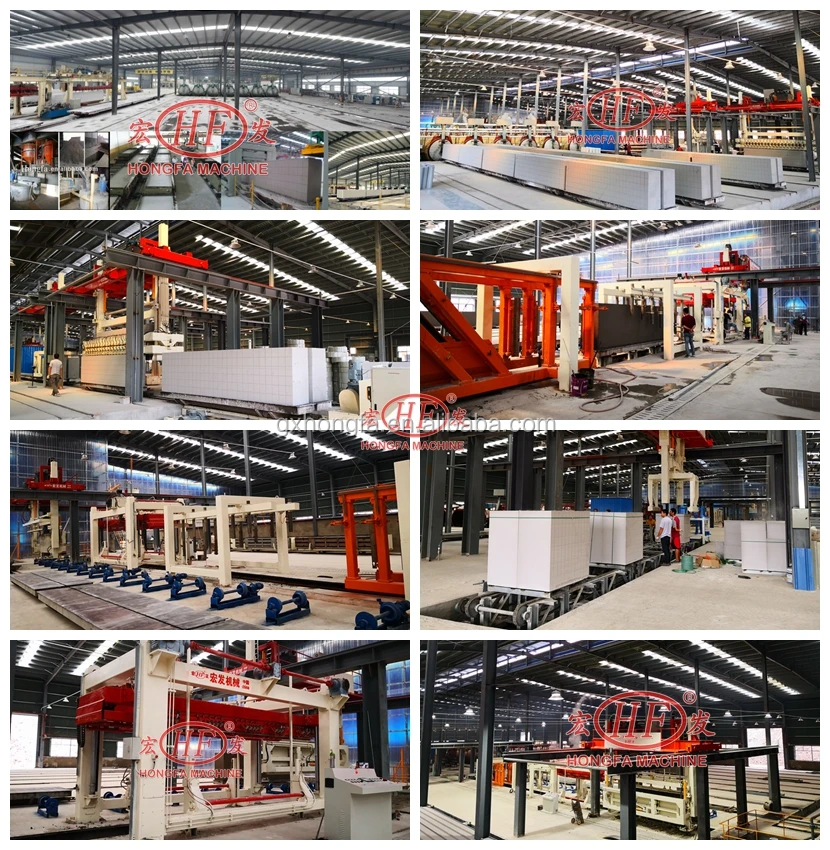

AAC concrete panel making machine block production line

aacblocks manufacturing plant aac block machine production line

Product Application

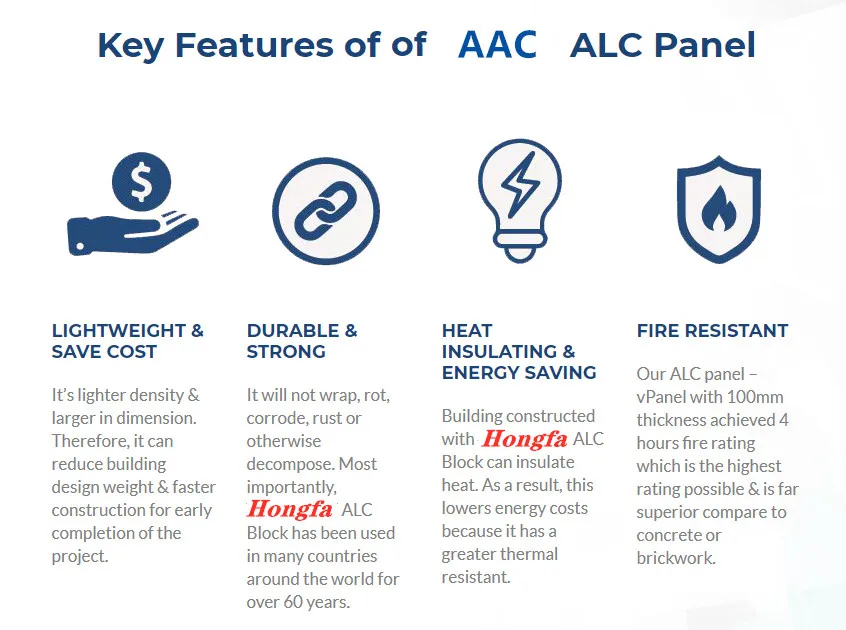

Autoclaved Aerated Concrete (AAC) has been used all over the world for decades, firstly produced in terms of industrial means in Sweden in 1923. It is a unique building concept, available in today's market with innumerable building advantages.

AAC is lightweight concrete that is produced under special circumstances, by adding aluminium paste which creates a porous shape into the mixture of cement, finely grounded quartz sand or flyash, water and limestone. AAC is very firm and the most durable construction material that provides heat insulation by its porous texture, security against earthquakes through its lightweight structure,and safety against fire by its non-flammable quality (Fire Class A1).

AAC building products can be used for all applications including every type of masonry walls, roofs and floors. AAC is largly preferred especially in many developed countries such as all EU countries, USA, Japan, Russia,Australia and all Gulf countries and Kingdom of Saudi Arabia,and most developing countries.

Brief introduction

Areated concrete brick (light brick ) is the light and porous buidling material. It has light weight keeping temperature cant burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Advantages

light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

keeping temperature

aerated concrete panel has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

General specification

| Common specifications of block | ||

| Name | Product grade | specification:length* width* high mm |

| AAC High-precision block | B04-A2.5 B05-A3.5 B06-A5.0 | 600*250*50 |

| 600*250*75 | ||

| 600*250*100 | ||

| 600*250*150 | ||

| 600*250*200 | ||

| 600*250*250 | ||

| 600*250*300 | ||

| AAC Ordinary block | B04-A2.0 B05-A3.5 B06-A5.0 | 600*250*100 |

| 600*250*150 | ||

| 600*250*200 | ||

| 600*250*250 | ||

| 600*250*300 | ||

According to product strength and bulk density (weight per cubic meter), it is divided into different grades. Commonly used are: strength A3.5, bulk density B06. The higher the strength, the lighter the bulk density

Size deviation

| Main technical indicators of AAC block | ||||||||

| items | Technical performance index | |||||||

| Density level | B03 | B04 | B05 | B06 | ||||

| Intensity level | A1.0 | A2.0 | A2.5 | A2.5 | A3.5 | A3.5 | A5.0 | |

| Compressive strength per cubic | average value(More than or equal to MPA) | 1.2 | 2.0 | 2.5 | 2.5 | 3.5 | 3.5 | 5.0 |

| Minimum(More than or equal to MPA) | 1.0 | 1.6 | 2.0 | 2.0 | 2.8 | 2.8 | 4.0 | |

| Average density (Less than or equal to kg/m³) | 300 | 425 | 400 | 525 | 500 | 625 | 600 | |

| Dry thermal conductivity [w(m.k)] | 0.08 | 0.11 | 0.13 | 0.15 | ||||

| Freezing resistance | Quality loss rate (Less than or equal to %) | 5.0 | ||||||

| Strength after freezing(MPA) | More than 80% of compressive strength per cubic | |||||||

| Drying shrinkage | Standard (Less than or equal to mm/m) | 0.50 | ||||||

| Combustion performance | Comply with GB8624-2012 Class A non-combustible | |||||||

aerated concrete panel programme

1,Technological Standard

The technological standard of this project is superior products according to the Chinese national standards. The equipments are made according to Chinese standard and criterion

This project provides the mature tilting technology in China.

2,Capacity

The product is AAC blocks with the capacity of 30,000m3- 300,000m3/year

3. Product specification

The products reach the block requirements of grade 04~07 of GB11968-2006

Main Material

coal ash sand waste mine material coal stonestone dust and other silicon materials.

1. Product weight is according to 600kg/m3 to control.

2 .annual capacity 200,000M3.

3. set raw material proportion: cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4. water and material rate 0.631

5. one mould product 2.88M3

6. Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7.casting slurry temperature 38-42 degree

8 .body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

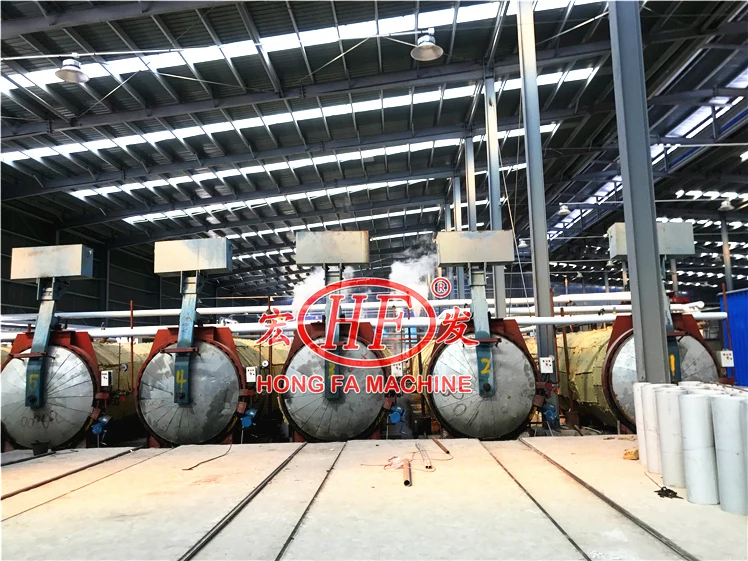

9 .Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!

Hongfa Machinery is your best choice

Brand and quality

We are a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine,concrete mixing plant,mixer,concrete block making machine,concrete tile making machine and concrete pipe making machine etc. with more than 30 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick & Tile field in China" and other honors.

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Exhibitions & cooperations

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, Sudan, etc., 132 countries and regions, deeply welcomed by clients from all around the world.

Hongfa Machinery Group Main Products :

Main products: Concrete mixing plant,mixer, concrete block making machine,concrete tile making machine and concrete pipe making machine .

Automatic Block Making:

QT12-15D QT12-15 QT10-15D QT10-15 QT9-15 QT8-15D

QT8-15B QT6-15D QT6-15C QT6-15B QT4-15D QT4-15C

QT4-15B QT4-20C QTJ4-25

Semi-automatic:

QTJ4-35B2 QTJ4-40B2

Semi-automatic egg-laying machine:

QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A

Color Paver Color tile forming machine:

QT3-20 SMY8-150

HF-800 pipe-making machine HF-2000 pipe-making machine

Concrete Mixing Plant:

HZS25 HZS35 HZS50 HZS60 HZS series

AAC Block production line : 50000~300000M3/Year

FAQ

When you plan to purchase a certain machine, suggesting to take care below points:

1. What is the brand? ( Now a lot companies embezzle our brand, pls take note our prevention fake-mark.)

2. Does this brand has good reputation and sell well in the market?(we got good reputation and are the biggest supplier in China)

3. What is the materials they used? Manganese steel or A3 steel? (We use Manganese steel which stronger than A3 steel)

4.What is the guarantee period? ( We guarantee for one year)

5.The price cover to what equipment?( pls refer to our quotation list)

Please not hesitate to contact us if you are interested in any kinds of products.

Contact Information:

Foreign Trade Dept. :Jiffy

Tel:0086-18260911699 (whatsApp)

Fax:0086-771-6036901

Guangxi Hongfa Heavy Machinery Co., Ltd.

Wesite: www.gxhongfa.cn