Машина для экструдирования жареных закусок кукурузных чипсов 2d

- Категории: Food & Beverage Machinery >>>

- Поставщик: Jinan,Dingrun,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

tortilla chip manufacturing machines for fried snack making extrusion factory

This Double-screw fried wheat flour snack processing line uses double screw extruding technique to replace the traditional steam booling process with high efficiency and no pollution without a boiler. The raw material can be total whear flour, or mixing with corn powder, rice powder, or others. By changing the moulds, the products can be in different shapes. After fried and flavored, the final snacks will be crispy and tasty. This line has features of continuous working, stable performance, and reasonable design.

Main Features of fried snacks food extruder mace

1) Simple structure in linear type ,easy in installation and maintation.

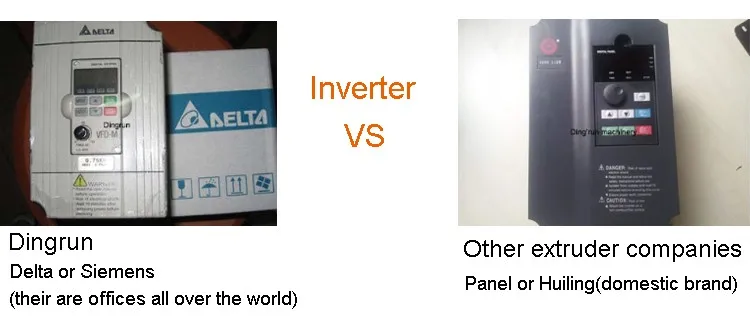

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

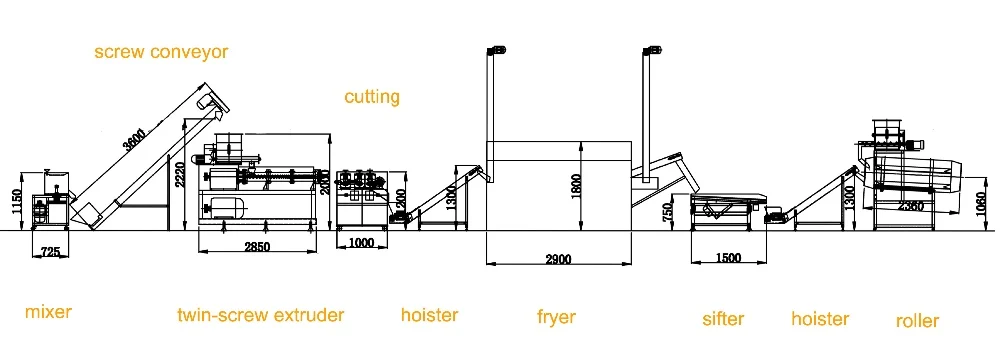

Flow chart:

grinding→mixing→extruding→frying→flavoring→cooling→packaging

Flow chart diagram:

Technical parameter for snacks food extruder

Modle | Installed Power | Power Consumption | Throughput | Dimension(mm) |

65 Processing Line | 45kw | 30kw | 150~200kg/h | 18800x4500x2400mm |

75 Processing Line | 80kw | 50kw | 250~350kg/h | 26000x5000x3500mm |

Raw material:

Final product:

By adjusting the mold in the cutting machine, you can choose various shapes such as ducklings, gourds, crispy corners, fish, etc.

Equipment list in the snack food production line:

mixer→screw conveyor→twin screw extruder→cutting→hoister→fryer→flavoring drum→cooling machine→packing machine

Name | Mixer |

Usage | To mix the raw materials evenly, fast speed, no leakage. |

Type | Vertical and horizontal type |

Motor | 3kw, 4kw, 7.5kw etc. |

Capacity | 20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. |

Material | stainless steel, carbon steel |

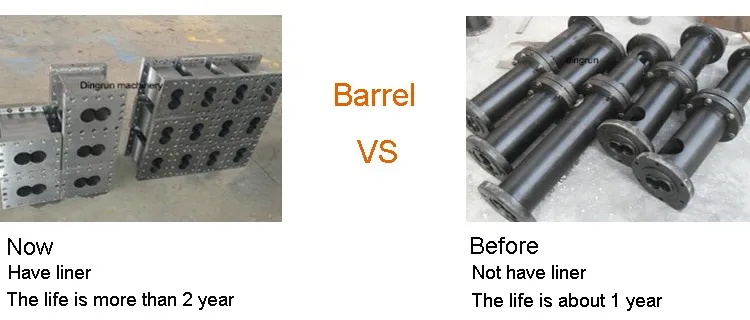

Name | Twin screw extruder (dry type/wet type) |

Usage | To extrude the raw materials and make them to the required shape and size of the corn snacks food pellets by mould |

Model | DSE65, 70, 85 |

Motor | 22kw, 37kw, 75kw |

Capacity | 100kg/h to 500kg/h |

Material | Screw materials 38CrMoAl stainless steel, carbon steel |

Name | cutting machine |

Usage | Embossed plastic for snack food |

model | DSE |

Motor | 0.75kw, 1.5kw |

Capacity | 100kg/h-500kg/h |

Material | stainless steel, carbon steel |

Name | Continuous Fryer |

Usage | Electric Belt and Upper Cover Lifting Setting .advantage of continuous production |

Type | electrical, steam, gas fired, diesel fired heating type |

Motor | KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc. |

Capacity | 100kg/h to 10 ton/h |

Material | stainless steel |

Name | Flavoring machine |

Usage | To mix the oil and flavors on the surface of the snacks food |

Type | single and double flavoring drum |

Motor | 0.75kw |

Capacity | 100kg/h to 500 kg/h |

Material | stainless steel |

Name | Packaging machine |

Usage | To pack the snack food with required weight |

Flowing Process | Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing |

Weight range | 1-5kg/bag, 5-25kg/bag, 25-50kg/bag |

Material | stainless steel, carbon steel |

Type | Automatic |

2.Factory layout and size suggestion

3.Provide general formulation

4.Custom-Design service

5.Professional Advice about Market, machines, materials, packing

6. Suggesting professional ship agent or helping book ship as customer request.

7. 24 hours online service

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory..

2.Free project planning and design services;

3.Free debugging of equipment until everything is functional;

4.Free management of equipments' long distance shipping;

5.Free training of equipment maintenance and operating personally;

6.Free new production techniques and formulas;

7. Provide 1 year complete warrantee and lifetime maintenance service

8.Online guide installation service

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers’

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.