Китайская фабрика низкая цена Q48 вешалка для спиннинга бластер полностью переработанный

- Категории: Abrator >>>

- Поставщик: Qingdao,Changjia,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

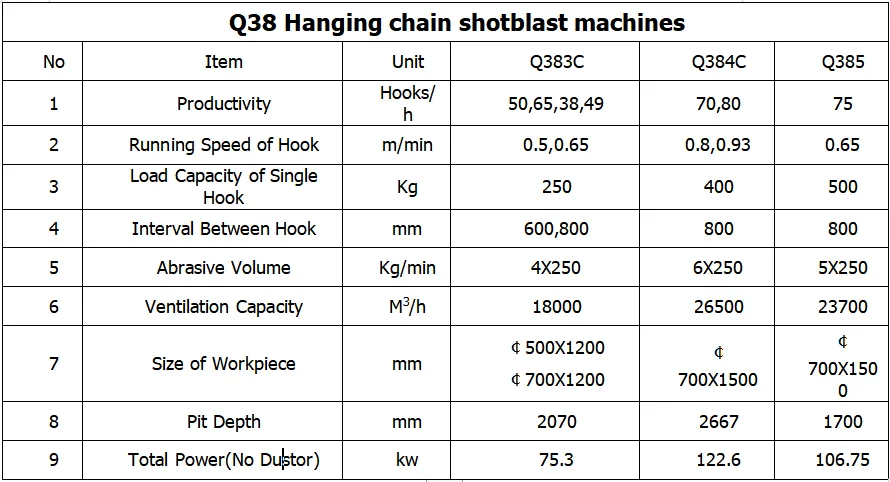

Характеристики

This machine has the characteristics of saving manpower and high production efficiency. It is suitable for surface cleaning and strengthening of small and medium-sized castings, forgings and heat-treated parts in mass production, especially for automotive parts, tractor parts, diesel engine casing, motor casing, valves and other industries.

Characters of this machine:

The layout of shot blasting chamber and shot blasting machine is confirmed by computer three-dimensional dynamic projection simulation.

The cantilever centrifugal shot blaster with (x30) high projection velocity can significantly improve the cleaning efficiency and obtain satisfactory cleaning quality.

The use of filter dust collector greatly reduced the concentration of dust emission and significantly improved the working environment.

Continuous cleaning, high degree of automation, shot blasting, peening, dust removal and other automatic operation, stop, the operation process can only be loaded and unloaded workpieces, greatly reducing the difficulty of operation of the equipment.

Scope of application: surface cleaning, polishing and strengthening of aluminium alloy die castings, zinc alloy die castings, copper castings, stainless steel precision castings, cast iron castings, motorcycle frame and steel products.

Characteristic:

1. Referring to the shot blasting machine in Germany in the late 1990s, we made it domestically.

2. The shot blaster is driven by a direct-connected motor, which is a variable-frequency motor with variable-frequency speed regulation.

3. Steel ball flow control valve can be micro-regulated, pneumatic opening and closing.

4. Adopt the world's most advanced core tube pulse back-blown dust removal system.

5. PLC is used to control the PLC controller in the electrical system. Mitsubishi of Japan is selected as the controller. Siemens or Omron products are selected as the electrical components.

6. Underground pit design.

shot blaster

1. The motor of shot blasting machine adopts excellent and controllable manufacturing process, with good sealing, dynamic balance, stable and reliable performance.

2. The shell of the shot blaster is made of 10 mm high-quality carbon steel plate by laser cutting and precise bending welding. The shell is positioned and welded with special tools to ensure the parallelism of the two ends of the shell and the concentricity of the holes.

3. The top guard board is precisely processed by die steel CNC, with the processing accuracy of ± 0.01; after machining, it is processed by low-pressure vacuum heat treatment.

Advantages

1. Adopt full manganese steel body + full manganese steel guard board, with a service life of 20 years;

2. Adopt automatic frequency conversion and speed regulation catenary conveying system;

3. Automatic control system of steel shot flow;

4. The main engine adopts 3-layer sealing structure, without any shot material leakage;

5. Adopt magnetic separation system + horizontal spiral separation + air separation separation separation system;

Remark:

.

Qingdao Changjia Machinery Co., Ltd., located in Lingang Industrial Park, West Coast New Area, the Ninth National New Area in China, is a backbone enterprise of foundry machinery and environmental protection machinery integrating scientific research, development, production, sales and service. The company has the right to import and export by itself and has passed the certification of ISO9001 international quality system. It has successively won the honorary titles of national high-tech enterprises, Qingdao Specialized New Demonstration Enterprises and other honorary titles. It also has a technology center of Qingdao shot blasting cleaning equipment enterprises, Among which the environmental protection type shot blasting machine has been recognized as a famous brand product in Qingdao by Qingdao Municipal People's Government. 。 The company has two pillar industries: cleaning machinery and environmental dust removal equipment. It is dedicated to the research, development, manufacture, installation and commissioning of shot blasting cleaner and environmental dust removal equipment. The product adopts 3D design, CNC plasma cutting, automatic welding, manufacturing center, and through cooperation with scientific research and academic structure, to ensure the performance of the product and the international advanced technology. At present, it has provided the overall solution for cost-effective surface cleaning and dust removal system for metallurgical foundry, automobile shipbuilding, construction chemical industry, mining engineering, railway locomotive and other industries in China. At present, a perfect service system has been established, which integrates design, manufacture, installation, commissioning, training, after-sales service, spare parts supply and equipment upgrade.

The company occupies an area of 60 Mu, with a building area of 20,000 square meters, and has more than 300 employees, including 58 professional and technical personnel. Through cooperation of research and development with universities, it has assimilated and absorbed advanced equipment manufacturing experience at home and abroad and improves the level of scientific research and development. Strong R&D strength, advanced production technology, perfect testing methods and scientific management system have made the company always at the advanced level in the same industry in China.

The company adheres to the quality policy of "integrating modern science and technology, making first-class products, providing sincere service and seeking common development", adhering to the working spirit of "meticulous and sincere", and sincerely hopes that friends from all walks of life will come to our company to guide, inspect and negotiate business. The company is willing to cooperate with all walks of life at home and abroad with advanced technology, modern management methods and high-quality staff to develop together, so as to make our manufacturing equipment cleaner, high-quality and efficient, to make our sky bluer, to create a prosperous future, and to build Chinese manufacturing of clean-up equipment and environmental protection equipment. Let us create a better future for Changjia, build the best level of Chinese manufacturing for cleaning equipment and environmental protection equipment, and work hard to lead the scientific and advanced development direction of the industry!

Q1: How to choose the suitable machines?

You only need to confirm your dimensions of workpiece,weight,productivity per day and target price. We will provide you with a

solution.

Q2: How about your MOQ?

Different machines, MOQ will be different, you can contact us for details.

Q3: How is the quality?

Our company has a completely scientific quality management system and more than 15 years experience of production in this filed We

guarantee the high efficiency performance of each product.

Q4: What can we do if your item doesn't work well?

Please email or call us, we will give analysis and solution as soon as we can.

Q5: Price, price, price?

We promise that you will get the best quality with the most reasonable pricing.