Сварочный аппарат с гидравлическим

- Категории: Seam Welders >>>

- Поставщик: Jinan,Hoayu,Automation,System,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

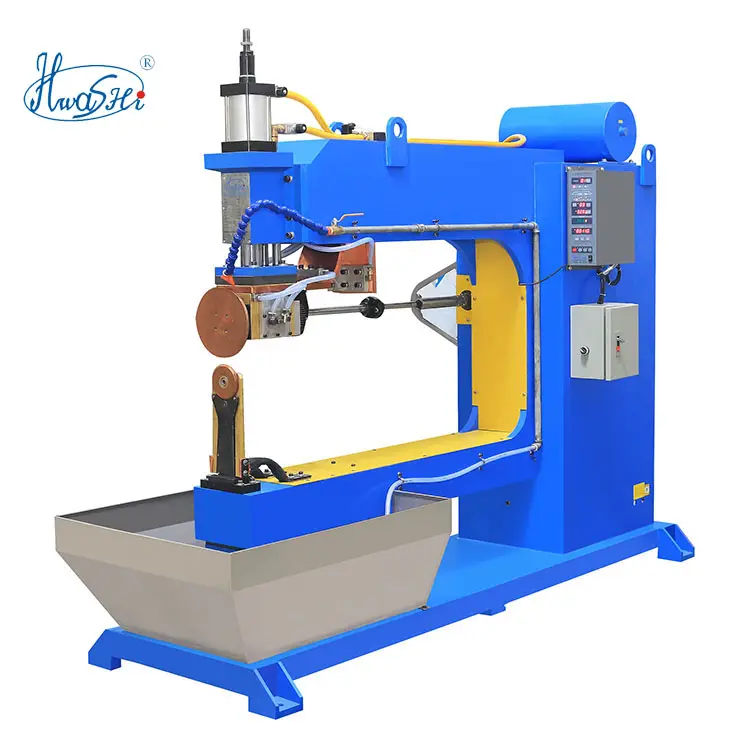

Hydraulic cylinder seam overlay welding machine

[Equipment composition]

It consists of machine body, rotary axis power mechanism, welding torch oscillating&adjustment mechanism, electric control system, welding power source, etc

1.Machine body

The machine body is composed of base, left and right side seat, gantry beam and other components. Base is welded by square tube and steel plate. After plane processing and stress relief treatment, base is used as installed datum plan. Rails are fixed on the base.

2.Rotary Axis Box

Rotary axis box is driven by AC frequency motor, and decelerated by worm and gear reducer. The inverter regulates and controls the rotation speed to realize rotation of rotary axis.

3.Welding Torch Pneumatic Feeding and Oscillating Lifting Mechanism

Welding torch moves forward-backward driven by air cylinder, to reach the switch between preparation and welding station. Oscillating mechanism is composed of stepper motor, ball screw and linear rail, etc.

4.Torch Clamping&Adjustment Mechanism

It adopts push-type wire feeding mode, to guarantee feeding stability. Welding torch can be adjusted up and down, left and right and angled turn. The fine adjustment of torch uses ball screw, with high accurate adjustment and positioning. It can be locked after adjustment.

5. Pneumatic Tail Stock

Pneumatic tail stock can be adjusted along with the guide rail to meet the requirements of various welding. The workpiece is pneumatically pressed by thimble, and rotates with thimble. Extending part is equipped with dust and splash protective device.

6.Universal Ball Support

It is guided by the guide rails, using ball screw manual adjustment mechanism to adjust up and down and locked. Universal ball supports the workpiece, to adapt to the workpiece adjustment in axial and circumferential direction, convenient to use.

7. Preheating Mechanism

There is preheating mechanism. The preheating torch is driven by the air cylinder to achieve the switch between preparation and preheating station. It can quickly reach the preheating position and start to preheat. To improve efficiency.

8. Electric control system

Japan OMRON PLC as control core to control the implementation of the welding program; Japan Omron 750w inverter; Oscillating mechanism uses stepper motor and driver; Stable system, simple structure and easy maintenance.

Rotary closed-loop encoder will detect welding length.Welding current, welding voltage, welding speed are controlled by D/A (digital-analog). Control button, touch screen, welding specification are placed in one integrated control panel box. Easy to be used and operated.

9.Welding source

Service condition:

1) When Sellers send engineer to Buyer's place for Installation, Commissioning and training for the machine in this contract in Buyer's place, Buyer shall undertake all the relative fees like, all tickets, accommodation for Seller's engineers.

2) Seller shall, within one week of receiving the above information, provide the required and qualified personnel to undertake supervision of installation, commissioning and training.

3) If the Buyer needs the service after sales from Seller, then Buyer shall undertake all the relative fees, like Round Tickets, Accommodation, Internal and international transportation, Labour cost of engineers etc.

4) When the Seller's engineer carries out the services in Buyer's place, Buyer shall arrange a Translator that can speak Chinese for Seller's engineer.

Ø Payment term: 30% T/T advance along with the purchase order, balance should be cleared before delivery

Ø Delivery time:60 days on receipt of payment in advance

Ø Guarantee: 12 months for the whole machine.