2020 Автоматическая текстурированная машина для производства овощей соевых бобов мяса протеина орехов

- Категории: Bean Product Processing Machinery >>>

- Поставщик: Jinan,Sunward,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

200-250KG/H small capacity Textured Soya/ Vegetable Protein Food Processing Line

No 1--The advantage of Twin-screw extruder:

1.The main extruder adopts frequency speed controlling with high automation.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5.It has the widest range of applications and can produce different products with different equipment and models.

No 2--The advantage of multi-layer oven:

1.We have four types of dryers, which includes fuel ovens, gas ovens, electric ovens, and high temperature inflated ovens (used to produce corn flakes).

2.The electric oven has three layers of five meters / five layers of five meters / five layers of eight meters / seven layers of eight meters / seven layers of eleven meters, etc., each layer has electric heating tubes, the purpose is to be more evenly heated.

3.Dryer is compact, has small dry area and a largesuperficial area. It also features small scale of heat elimination and high thermal effciency.

4.Mesh belt conveyors and thermal insulation boards all use stainless steel material, making the equipment clean and sanitary.

5. The speed of mesh belt conveyor is adjustable, the drying period for food in the oven can be adjusted.

6. The automatic temperature control system makes it possible to set the temperature according to your needs.

No 3--The advantage of cooling machine:

1.General length is 5 meters, but we can made it according to our customers' requirement.

2.The above are fans, which used to speed up the cooling.

3.The goods are transferred by the belt while they are cooling by fans.

4.Material touching the food is stainless steel.

5.Transferring speed can be adjusted.

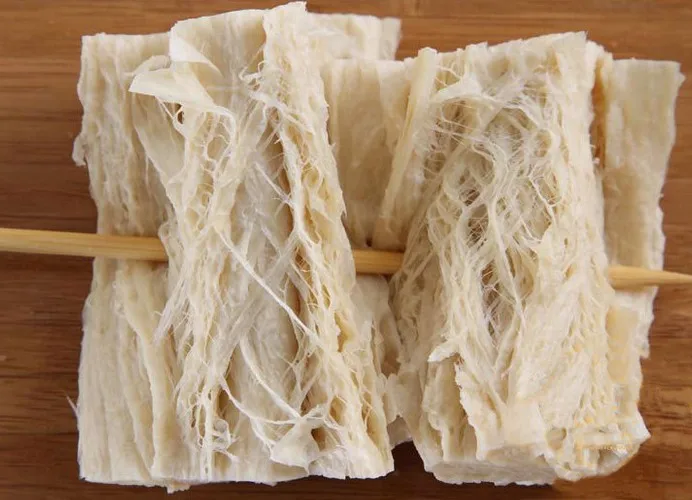

No 4--The introduction of textured soy protein:

1.Textured soy protein is made from defatted soy flour, which is low oil soy material. So it is plentiful in supply. It is with a great source of vegetable protein without all the fat. soybean meat equipment comes in small dry chunks resembling, dried vegetable more than anytihng, or in a finely -ground form. It's flavorless, but when you rehydrate it and add your own flavors, it makes a great protein-filled addition to many dishes calling for ground meat. Because of its varying texture, it's versatile, and can take on the texture of many meats. For instance, it's excellent in chili, tacos, veggie burgers and soups. It can be boiled in high temperature with different tastes, or added into meal product as stuffing. When it's used to replace meat in stews and soups, your family will hardly be able to tell the difference and since you can marinate it in many of the same sauces as meat, it can take on meat's flavors.

2.Capacity: 100--600kg/h(soy protein machine food grade textured soy protein)

No 5--The whole line of TVP/TSP:

1. Processing line: Mixer---Screw conveyor---Twin-screw extruder---Air conveyor---Dryer---Cooling machine

2.Voltage( textured soy protein) : Three phases: 380V/50Hz, Single phase: 220V/50Hz. we can make it according to customers' Local voltage according to different countries.

Cooling machine

Installed Powder: 1.25kw

Powder Consumption:1kw

Material: Stainless steel

Dimension: 5300*690*1470mm

Fans: 0.12kw

Weight:100kg

Function: The air from the fan cooling the meat analogue going through the conveyor belt

Air Conveyor

Installed Powder: 0.75kw

Powder Consumption:0.5kw

Material: Stainless steel

Weight:50kg

Function: Air conveyor conveys the food relying on the wind-force from the blower. It is more suitable for the long distance conveying low energy-consumption, high efficiency.

Screw Conveyor(SL-I)

Powder Consumption:0.5kw

Material: Stainless steel

Weight:100kg

Electric dryer(three layers five meters)

Installed Powder: 27kw

Powder Consumption:18kw

Material: Stainless steel

Dimension: 5200*1300*2200mm

Weight:1500kg

Function: Bake all kinds of puffed food/pet food/bread crumbs and so on.

Twin Screw extruder(TSE 85)

Powder Consumption:60kw

Material: Stainless steel

Dimension: 18000*1300*2300mm

Weight:1500kg

Mixer(BF-II)

Installed Powder: 4kw

Powder Consumption:3kw

Material: Stainless steel

Capacity: 40kg/batch

Weight:60kg

Dimension: 1030*720*1350mm

Mix the materials with water or other liquid.

Model | TSE 65 | TSE 85 | TSE70 |

Installed powder | 90kw | 160kw | 100kw |

Production Capacity | 200-260kg/h | 300-550kg/h | 250-350kg/h |

Dimension | 18000*1300*2200mm | 22000*3500*3200mm | 20000*1400*2200mm |

Jinan Sunward Machinery Co.,Ltd

Jinan Sunward Machinery Co., Ltd is an industry and trade integrated enterprise. The company is committed to R & D extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, Core filling snack system,artificial rice system, fried snacks machine, modified food starch etc.

Jinan Sunward Machinery Company is founded in 2008. For supplying best service, technology department, Sales department, producing department , after- sales department are always available for you. Sales department includes two international sales department and two domestic sales department. One sale department is located in Wu Jia Pu Industrial Park,Jinan. The other sale department is located in No 130 Wu Ying Shan Middle Road, Jinan.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. Machines are welcome in the countries. So until now, there are not only direct customers, but also some long term cooperation agents. Such as Indonesia agent, Iran agent, Nigeria agent and so on.

We have obtained ISO9001 and CE certifications, believe me, you can trust us. If you want to get more details about our machines, please do not hesitate to contact us.

2. Packaging: inside is covered in plastic film, outside is wooden case.

3. Shipping: 15-35 working days after receiving deposit.

1. What's the pre-sale service of your company?

Related machines's technical parameter will be supplied to customer.

1). According to customer's factory size, factory layout can be provided in advance.

2). According to customer's material cost, general formulation can be prepared well.

3). Special machine can be supplied as customer's request.

4). Professional Advice about Market, machines, processing , materials, packing can be supplied.

5). Suggesting professional ship agent or helping book ship as customer request.

2. What's the after-sale service of your company?

1). Allocation chart as the buyer's request will be supplied.

2). Operation manual will be supplied after shipment.

3). One year warrantee, life time maintenance with cost price.

4). Free easy broken spare parts will be sent with container .

5). First installation can be done by engineer.

6). Training workers in customer's factory.

3. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

4. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.

5. What is the minimum order?

Yes, our company mainly deals with wholesale deals,but if you insist buying one set,or you just need one set,we would be very likely to make the MOQ as 1 set for you though.

6.How long is the warranty time for your products?

Our officially promised warranty time is one whole year after delivery at best.

7.I haven't done business with you guys before,how can i trust your company?

Our company has been in Alibaba.com for 9, almost 10 years,which is longer than most of our fellow suppliers,we've been golden suppliers for years.what's more,we've got quite a lot authority certificates,for example,CE, ISO9001, Alibaba on site check certificate. If you also have some questions, welcome to visit our factory, we will provide the best service and machines for you. I hope those above will be persuasive enough.

8. Do you give any discount ?

I'll surely try my best to help you get those by the best price and good service at the same time.