Биореактор л биореактор промышленный

- Категории: Реакторы >>>

- Поставщик: Shanghai,Beyond,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

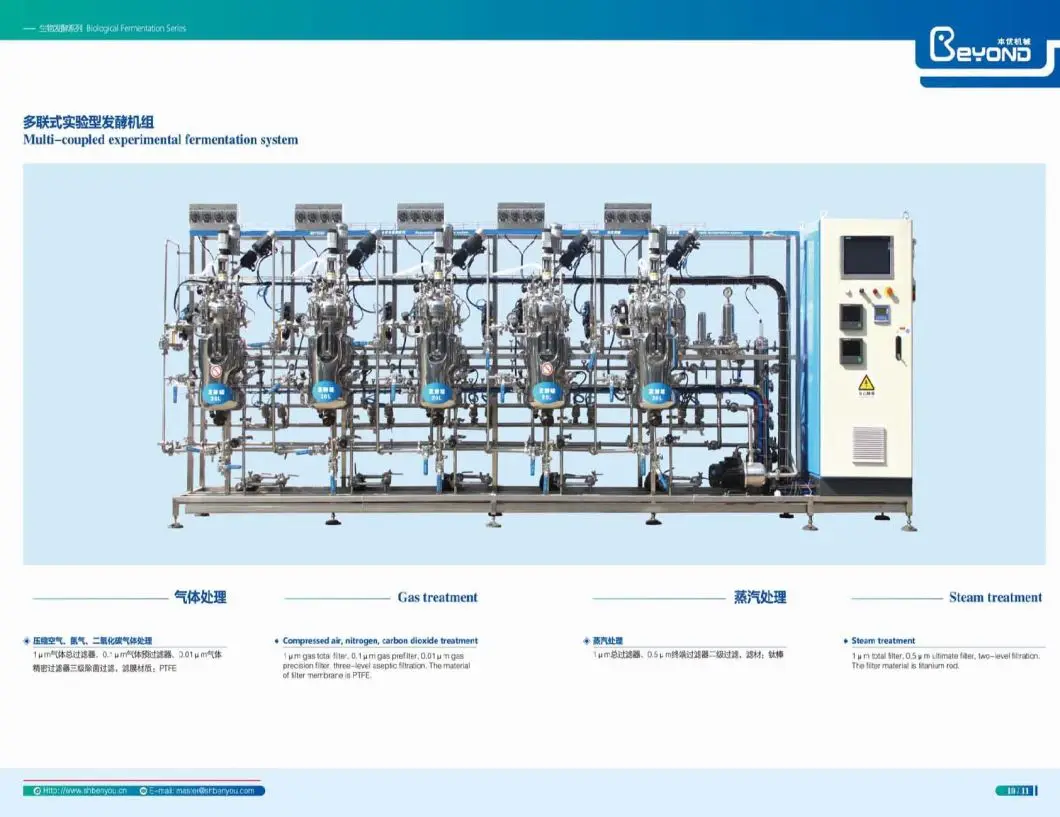

Product Description

Bioreactor refers to equipment that uses live cells or enzymes as biocatalysts to provide a suitable environment for cell proliferation or biochemical reactions. It is a key device in the biological reaction process. The choice of bioreactor structure, operating mode and operating conditions has a close relationship with the quality, yield (conversion rate) and energy consumption of biochemical products. The design and amplification of bioreactors are the central content of biochemical reaction engineering and an important part of biochemical engineering.

Material | AISI304/316 |

Processing type | Microbial fermentation;antibiotic fermentation;nucleic acid fermentation,enzyme fermentation,yeast fermentation;starter fermentation |

Reducer motor | RF helical gear,FAF parallel shaft helical gear,SAF turbine helical gear,two stage energy effciency viriable frequency motor |

Control type | Siemens PLC full-automatic touch screen control; |

PH control precision | <0.2 |

Temperature control precision | ±0.1 |

Direction for use

From the perspective of the biological reaction process, the reactor used in the fermentation process is called a fermentor; the reactor used in the enzyme reaction process is called an enzyme reactor. Plant cell culture device.

Description of application effect

Fermentation tanks can be distinguished according to their use objects, including: anaerobic fermentation tank, aerobic

fermentation tank, sewage biological treatment device, etc. Among them, the anaerobic fermentation tank is the simplest, it does not need to introduce air during production, only a vertical or horizontal cylindrical container, and the tank can be stirred by the carbon dioxide generated during fermentation.

fermentation tank, sewage biological treatment device, etc. Among them, the anaerobic fermentation tank is the simplest, it does not need to introduce air during production, only a vertical or horizontal cylindrical container, and the tank can be stirred by the carbon dioxide generated during fermentation.

Detailed Images

Fermentation tanks are distinguished by operating modes, which are divided into batch operation and continuous operation. The former generally uses a kettle reactor, and the latter can use a continuous stirred reactor or a tube and tower reactor. Aerobic fermentation tanks are based on energy input methods: fermentation tanks with mechanical agitators and air distributors,circulation pump fermentation tanks, and bubble tower fermentation tanks.

Related Products

Packing&Shipping

Standard Export Package including Wooden case,PE wrap film,Carbon Steel

After Sales Service

After Sales Services

1.Installation and commission on site;

2.Online technical video support;

3.Spare parts;

4.Maintenance services

2.Online technical video support;

3.Spare parts;

4.Maintenance services

Company Introduction

Shanghai Beyond Machinery Co., Ltd is a professional technology developing enterprise which mainly engaged in healthy equipment fields. Combined with R& D, procedure design service, turnkey base project, equipment manufacturing, installation, commissioning and training, our company is specialized in turnkey projects services widely applicable to food industry such as fruit and vegetable juice, dairy product and beverage, meat and bone, egg product, etc. and others include pharmaceuticals and fine chemicals as well. Beyond acted as pioneer to introduce and absorb advanced international technology and procedures, continuously innovate and positively promote deep communication and cooperation inside industry, which high effectively push industry develop healthily and orderly.

Our Services & Strength

Installation and commission on site;Online technical video support;Spare parts;Maintenance services; Oversea service agent; local exhibiton hall.

FAQ

A bioreactor is a device system that uses enzymes or organisms (such as microorganisms) to perform biochemical reactions in vitro. It is a biofunction simulator, such as a fermentation tank, immobilized enzyme, or immobilized cell reactor. Wait. It has important applications in alcohol, pharmaceutical production, concentrated jam, fermentation of fruit juice, and degradation of organic pollutants.