Передвижной дизельный используется каменной Щековой дробилкой завод на

- Категории: Mining Machinery >>>

- Поставщик: Henan,Mingxin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

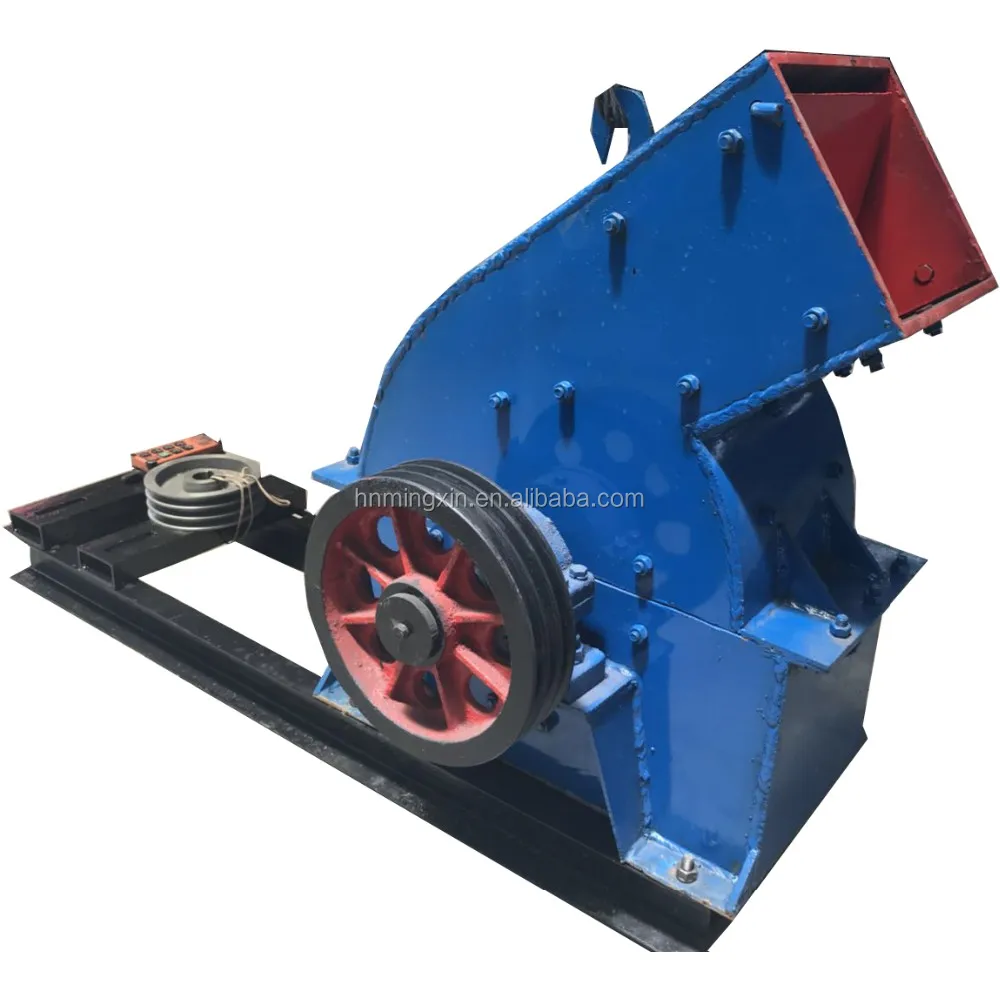

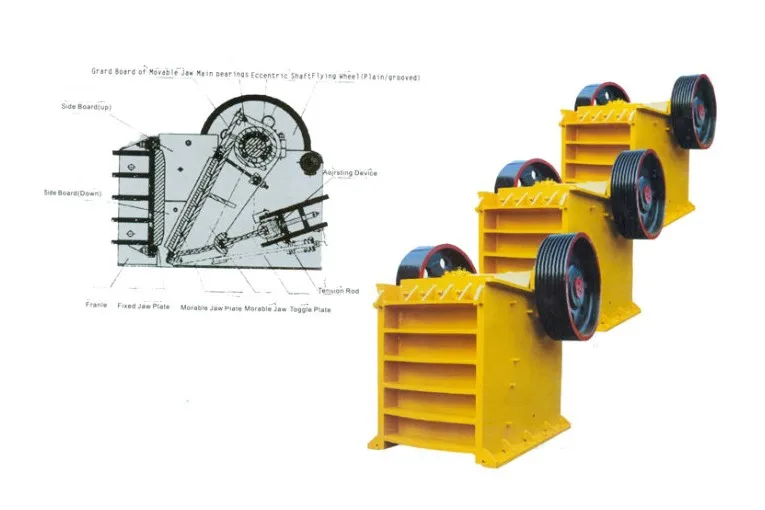

Description of mobile diesel used stone jaw crusher plant for sale

mobile diesel used stone jaw crusher plant for sale is mainly used as the coarse crusher and intermediate crusher in the mining, building materials, infrastructure and other sectors. It is divided into large, medium and small size according to the feed mouth width. The width more than 600mm is the large size, 300-600mm is the medium size, less than 300mm is the small size. Jaw crusher is easy to manufacture and works reliably with simple structure.

Model | Feed size | Max Feeding size(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Dimension(mm) |

PE-150*250 | 150*250 | 125 | 1-3 | 5.5 | 0.8 | 720*660*850 |

PE-200*300 | 200*300 | 180 | 2-6 | 7.5 | 1.2 | 910*750*990 |

PE-200*350 | 200*350 | 180 | 3-10 | 11 | 1.5 | 1000*870*990 |

PE-250*400 | 250*400 | 210 | 5-20 | 15 | 2.8 | 1300*1090*1270 |

PE-400*600 | 400*600 | 340 | 16-60 | 30 | 7 | 1730*1730*1630 |

PE-500*750 | 500*750 | 425 | 40-110 | 55 | 12 | 1980*2080*1870 |

PE-600*750 | 600*750 | 500 | 80-240 | 55 | 15.8 | 2070*2000*1920 |

PE-600*900 | 600*900 | 500 | 50-180 | 55 | 17 | 2190*2260*2300 |

PE-750*1060 | 750*1060 | 630 | 110-320 | 110 | 29 | 2660*2430*2800 |

PE-800*1060 | 800*1060 | 640 | 130-330 | 110 | 29.8 | 2710*2430*2800 |

PE-830*1060 | 830*1060 | 650 | 150-336 | 110 | 30.7 | 2740*2430*2800 |

PE-870*1060 | 870*1060 | 660 | 190-336 | 110 | 31.5 | 2810*2430*2800 |

PE-900*1060 | 900*1060 | 680 | 230-390 | 110 | 33 | 2870*2420*2940 |

PE-900*1200 | 750900*1200 | 850 | 220-450 | 110 | 52 | 3380*2870*3330 |

PE-1000*1200 | 1000*1200 | 850 | 315-500 | 110 | 55 | 3480*2876*3330 |

PE-1200*1500 | 10201200*1500 | 1200 | 400-800 | 160-220 | 100.9 | 4200*3300*3500 |

PE-1500*1800 | 1500*1800 | 1200 | 500-1000 | 280-355 | 139 | 5160*3660*4248 |

PE-1600*2100 | 1600*2100 | 1500 | 1300-2200 | 350-380 | 150.6 | 6210*4013*4716 |

PEX-150*750 | 150*750 | 120 | 8-25 | 15 | 3.8 | 1200*1530*1060 |

PEX-250*750 | 250*750 | 210 | 13-35 | 22 | 5.5 | 1380*1750*1540 |

PEX-250*1000 | 250*1000 | 210 | 16-52 | 30 | 7 | 1560*1950*1390 |

PEX-250*1200 | 250*1200 | 210 | 20-61 | 37 | 9.7 | 2140*1660*1500 |

PEX-300*1300 | 300*1300 | 250 | 16-105 | 55 | 15.6 | 2720*1950*1600 |

Main Features of mobile diesel used stone jaw crusher plant for sale

1. Low noise, less dust.

2. The high crushing ratio, uniform product granularity.

3. Simple structure, reliable work, low operating costs.

4. The lubrication system is safe and reliable, easy to replace parts, and the equipment maintenance is simple.

5. Crushing cavity is deep and there is no dead zone, so as to improve the feed capacity and output.

Crushing ratio of mobile diesel used stone jaw crusher plant for sale

The crushing ratio is an important index to evaluate the jaw crusher. The crushing ratio of jaw crusher is the ratio of raw material granularity and the product precision after crushing. It indicates the degree of reduction of raw material after crushing. When the ore is broken, the granularity becomes smaller, and the ratio of the granularity of the ore before crushing and that of the ore after crushing is known as the crushing ratio, which indicates the decreased numerical value of the granularity after the ore crushing.

Raw material of mobile diesel used stone jaw crusher plant for sale

Raw material of mobile diesel used stone jaw crusher plant for sale: gravel, granite, basalt, iron ore, limestone, quartz rock, diabase, gold, cooper and so on.

Packing of Jaw Crusher Machine: container

Delivery of Jaw Crusher Machine: within 20 working days after receiving your deposit

We offer 5 different main varieties products which include charcoal machine, garbage disposal equipment, mineral processing equipment, wood processing equipment, grain and oil equipment to numerous overseas customers. In the meanwhile, favorable and complete service is our obvious advantage which compare with other companies in our industry. We support site inspect our products, and Engineers are available at any time as well. As a result of our high quality products ans outstanding customer service, Mingxin has gained a global sales network reaching to South Africa, Pakistan, Vietnam and other countries.

1. 24 hours all day service

2. Can be customized according to customer needs.

3. Check again before we send the goods.

4. Send the goods on time.

5.One year warranty from the date of receiving.

6. We can test the machine before we send it if the client need.

7. The more you need, the cheaper the unit price is.

Our machine in South Africa