Oem/odm изготовленные на заказ трубы для сварки cnc детали металла услуги

- Категории: Sheet Metal Fabrication >>>

- Поставщик: Zhongshan,Yishang,Metal,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Company Profile

\t\t\t\t\t\t\t\t\tProduct Details \t\t\t\t\t\t\t

Yishang specializes in manufacturing and customizing all kinds of display products, including light box, indicator, letter sign, display stand, display cabinet and so on.

For custom display products, Yishang has the following advantages:

1. We can provide the free 3D sketch and rendering within 24 hours.

2. 24 hours online service.

3. Capabilities of telephone and email communication, complete the design and quotation within 24 hours.

4. For face-to-face communication, the salesman, technician and price officer cooperate with each other, complete the design and quotation within 2 hours.

5. The delivery time of simple display products are within 10 days, complex display products are within 20 days.

For custom display products, Yishang has the following advantages:

1. We can provide the free 3D sketch and rendering within 24 hours.

2. 24 hours online service.

3. Capabilities of telephone and email communication, complete the design and quotation within 24 hours.

4. For face-to-face communication, the salesman, technician and price officer cooperate with each other, complete the design and quotation within 2 hours.

5. The delivery time of simple display products are within 10 days, complex display products are within 20 days.

Product Name | China oem/odm custom sheet weld parts metal welding services metal fabrication | |||

Technology | Metal welding metal fabrication services | |||

Service | Custom OEM ODM sheet metal fabrication parts/enclosure services | |||

Cutting: use laser cutting machine to cut 60*60* 4.0mm iron tube and 4mm thick cold rolled steel plate.

Weld the flat spread bead along the length of the low carbon steel plate, with the gap between the bead and the bead being 20-30 mm. Check the weld quality after each weld. The weld surface should be clear and evenly corrugated.

The protection of the tungsten extreme head is complete, the loss of the tungsten electrode is less, and the tungsten inclusion defect will not occur when the arc is started.

The protection of the tungsten extreme head is complete, the loss of the tungsten electrode is less, and the tungsten inclusion defect will not occur when the arc is started.

Welding: 4mm thick low carbon steel plate and 60 *60 *4 mm iron pipe for welding, we use the arc initiation tungsten argon arc welding process.

Advantages of argon tungsten arc welding: the tungsten electrode can directly ignite the arc on the welding spot

without contact with the welding piece by keeping a certain distance between the tungsten electrode and the welding piece.

Advantages of argon tungsten arc welding: the tungsten electrode can directly ignite the arc on the welding spot

without contact with the welding piece by keeping a certain distance between the tungsten electrode and the welding piece.

Product quality inspection:

We strictly follow the quality control requirements, from the raw materials, production process, surface treatment and finished products and other processes for quality control.

(1) raw materials inspection, to ensure the use of materials and customer requirements.

(2) In each production process spot check, to ensure that each product from the material, forming, welding, can meet the customer's requirements.

(3) product surface treatment detection, to ensure that can provide high quality, smooth surface effect.

(4) Our professional quality inspectors will test the finished products according to the requirements of different items of the product to ensure that the products 100% meet the requirements of customers. Can ensure that the supplied products meet customer standards, can greatly reduce customer concerns about product quality.

We strictly follow the quality control requirements, from the raw materials, production process, surface treatment and finished products and other processes for quality control.

(1) raw materials inspection, to ensure the use of materials and customer requirements.

(2) In each production process spot check, to ensure that each product from the material, forming, welding, can meet the customer's requirements.

(3) product surface treatment detection, to ensure that can provide high quality, smooth surface effect.

(4) Our professional quality inspectors will test the finished products according to the requirements of different items of the product to ensure that the products 100% meet the requirements of customers. Can ensure that the supplied products meet customer standards, can greatly reduce customer concerns about product quality.

What other customized tube fabrication products we can make?

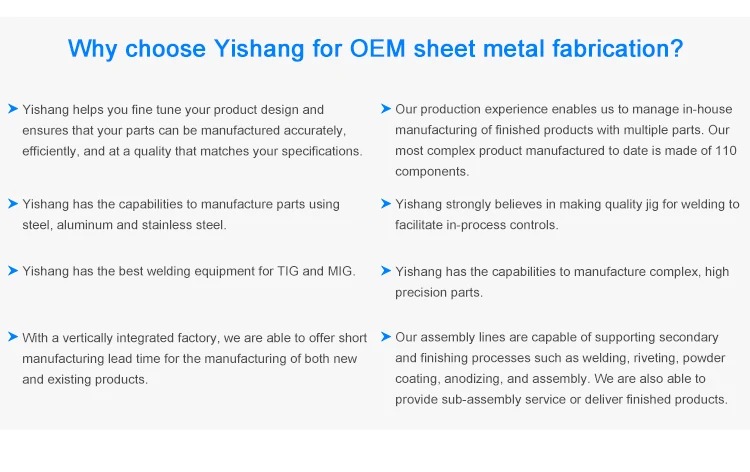

Why Choose Us

Packing and Shipping