840-900 мм Двухслойный стальной лист кровельный гофрированный профилирующий

- Категории: Машины для производства плитки >>>

- Поставщик: Cangzhou,Dixin,Roll,Forming,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

840-900mm Double Layer Steel Sheet Roofing Corrugated Roll Forming Machinery

for this double layer metal sheets roofing machine, you can choose corrugated and trapezoid type, also can choose IBR and wave type,by this design, can save space and cost, but kindly note one thing: both layers cannot run at same time

1.Panel drawing for your reference

2.

Technique parameters

1.Processing material | aluzinc/galvanized steel/colored steel coil |

2.Material thickness | 0.3-0.8mm |

3.Feeding width: | 1000mm or customer request |

4.Effective width | 900-840mm or customer request |

5.Main motor power | 4kw |

6.Pump station power | 4kw |

7. Shaft diameter | 75mm |

8.Forming steps | 13steps |

9.Main frame | 300H steel frame |

10. Side plate thickness | 16mm |

11.Roller material | 45# forged steel, with hard chrome plating |

12.Control systerm | (Taiwan brand)Delta PLC control system with touch screen |

13.Cutting blade material | Cr12 |

14.Working speed | Glazed tile 2-4m/min,another two design About 8-12m/min |

15. Transmission way | 1 inch chain drive |

16. Machine size (mm) | About 7000*1500*1500mm |

17. Machine weight | About 4.5t |

18.Power supply | 380v,3phase,50hz or accodring to customer request |

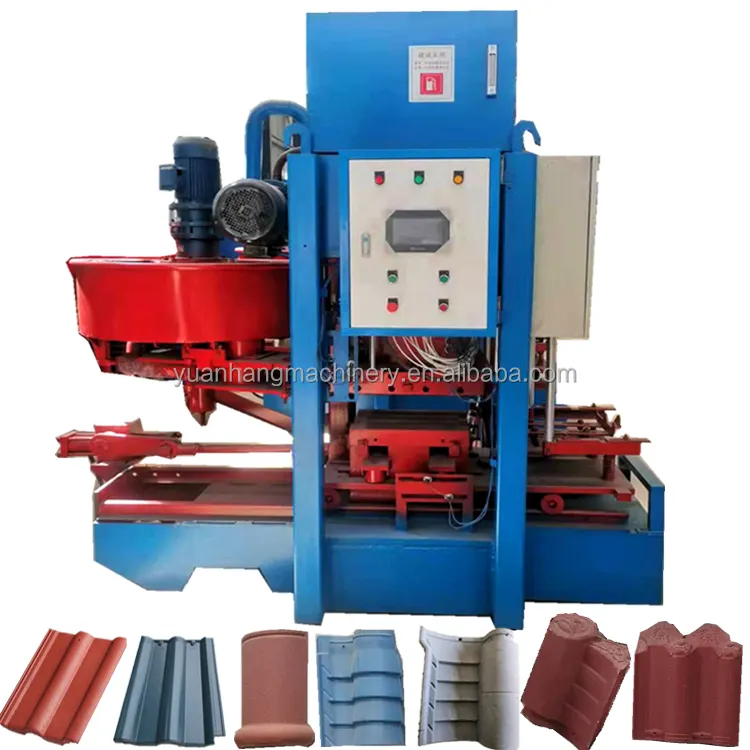

3.Some machine pictures for your reference .

Cangzhou Dixin Roll Forming Machine Co.,ltd is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. We specialize in the automated production line of sheet cold roll forming machines. We are able to provide an integral resolution schema of cold roll forming system through a combination of advanced system design and equipment. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely.

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,shutter door machine, floor decking machine and other associated equipment. Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

Our company has been adhering to the quality first, reputation first business philosophy, our company production and operation of various cold bending molding equipment for more than 10 years, our company has the most advanced technical team and rich production experience, can according to your needs to produce machines.

Our customer from all over the world,welcome you visit our factory!Please feel free contact Bella Tel/what'sapp:0086 18231723279

Cangzhou dixin roll forming machine co.ltd has exported its equipment and machines to more than 80 countries over the world, such as Russia, India, Australia, Malaysia, Nigeria, Romania, Rwanda,Tanzania,Kenya,Philippines, Indonesia,South Africa,Mauritius,Mexico,etc. It has received excellent reputation. In the future, we are committed to better equipment and sales service and meeting customers’ requirements when and where they need.

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

3.What about your warrenty?

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost .