Медицинская маска для лица Полиэтиленовая сумка нетканые ткани meltblow 100% pp Нетканая ткань N95 полипропилен BFE

- Категории: Промышленная ткань >>>

- Поставщик: Ruian,Sanlin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

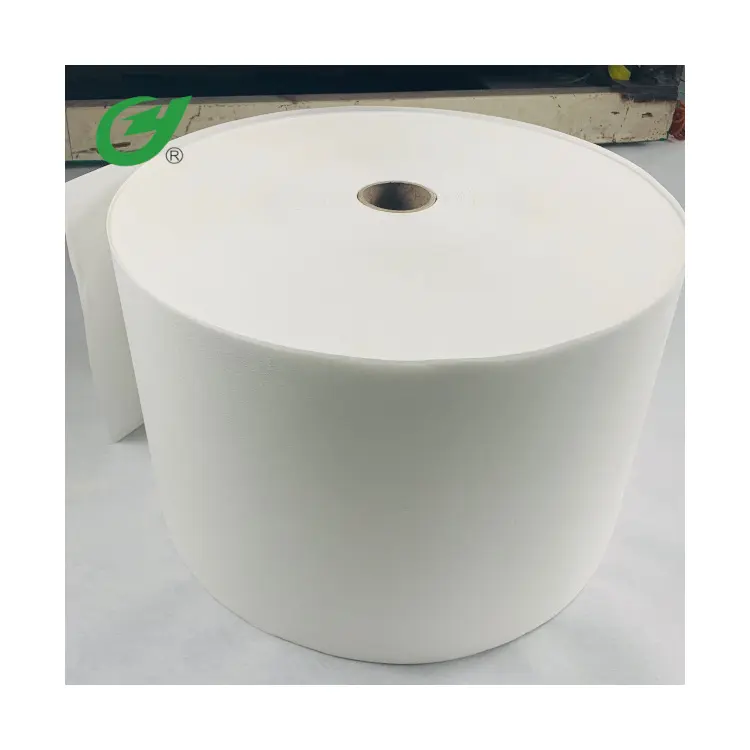

| meltblown 100%pp nonwoven n95 fabric medical face Mask non woven fabrics for face Mask roll |

Melt-blown non-woven fabric is a kind of ultrafine fiber non-woven material made by melt-blown process, raw material is food grade PP, fibre diameter can be 0.5um-2um. The product is treated with special electrostatic, characteristics of high efficiency and low resistance, comfortable and easy to adorn. Can effectively filtration and adsorption of microorganisms, viruses and extremely dust.

Medical grade mask filter can meet with Europe standard EN14638:2003 requirements, the bacterial filtration efficiency(BFE) is over 99%.

Industry grade mask filter can meet with Europe standard EN149:2001 FFP1/FFP2/FFP3 requirements, and USA standard NIOSH 42 CFE-84 requirement such as N95/N99/N100 etc.

Item | BFE95 Melt blown nonwoven fabric |

Material | 100% Polypropylene |

width | 0.15-3.2m |

Color | White |

Weight | 20gsm recommended |

Pattern | Embossed |

Package | 2000m per roll, 5 rolls into polybags and nylon bags |

Melt-blown fabrics have generally the same applications as other nonwoven products. The main uses of melt-blown nonwovens and other innovative approaches are as follows.

1. Filtration

The porous nonwoven melt-blown fabrics can be used in the filtration of gaseous as well as liquid materials. These applications include water treatment, masks, air conditioning filter, etc.

2. Sorbents

Nonwovens are capable to retain liquids several times of their own weight. For instance, polypropylene nonwovens are ideal to recollect oil contaminations.

3. Hygiene products

The high sorption efficiency of melt-blown nonwovens can be exploited in disposable diapers, sanitary napkins and other feminine hygiene products as well.

4. Apparels

The good thermal insulation properties, the barrier behavior against fluids combined with breathability make melt-blown nonwovens a great choice for apparels even in harsh environments.