Картонная машина для бумажных

- Категории: Paper Product Making Machinery >>>

- Поставщик: Longkou,Fuchang,Packing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

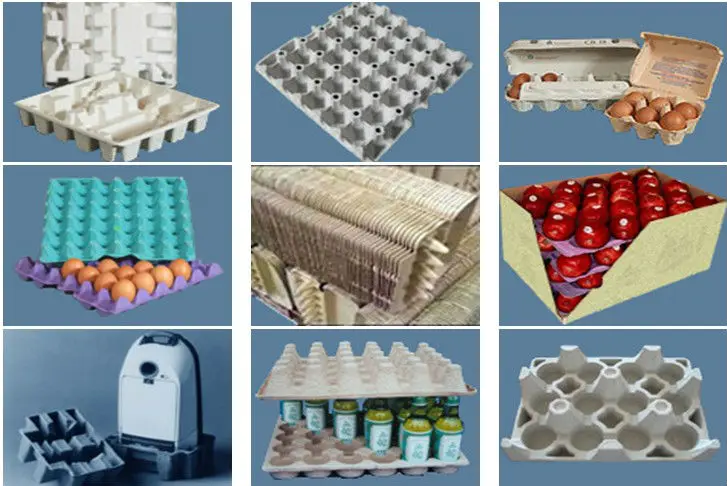

Paper pulp molding-egg tray machine production line

Paper pulp molding/moulding product is a kind of packaging which is made from waste paper and pulp cardboard by appropriative equipment and unique technics. Firstly,paper pulp molding/moulding products are only applied to the transport packaging of farm produce such as egg ,fruit and so on. But gradually,the range of application and research is enlarged to the safeguard packaging of industrial product,such like electronic product, household appliances, apparatus,glassware, crockery, minitype machine etc..

Paper pulp molding/moulding mostly use cheap waste paper as raw material to make not only valuable but also environmentally friendly products.It can greatly cut down the use of plastic,and reduce environmental pollution.What's more,it also discover a new way to recycle waste paper at the same time .

Paper pulp molding/moulding product has good intensity and elasticity ,and also is ventilated,anti static,which can reduce the transport cost .What is more ,it can be recycled ,which is good for environmental protection .So that ,foam packaging is replaced by the paper pulp molding/moulding product at present .And the application range has spreaded to many fields such as :egg tray ,egg carton ,fruit tray and industrial packaging of glassware , apparatus ,tool , electrical appliances , accessory , vegetable portion trays, fruit portion trays, strawberry punnets , kidney trays, wine packs, can trays, seed cubes,coffee tray,bottle tray,seeds tray,paper shoe tree or paper shoe filler and so on . The paper pulp molding/moulding product factory belongs to our company can produce all kinds of packaging product according to the demand of the customer.

Model | Capacity | Forming machine | Drying system | Workshop | Rated power |

FC-ZMW-2 | 750 pcs/hour | Reciprocating | Automatic | 30*1.8*2.45m | 50/85KW |

FC-ZMW-3 | 1000pcs/hour | Reciprocating | Automatic | 30*1.8*2.45m | 60/90KW |

FC-ZMW-4 | 1300pcs/hour | Reciprocating | Automatic | 30*1.8*2.45m | 70/105KW |

Model | Capacity | Forming machine | Drying system | Workshop | Rated power |

FC-ZMG3-12 | 2000-2500 | Rotary | Single layer Multi-layer | 10*2.2*2.45m 40*2.2*2.45m | 80/120kw |

FC-ZMG4-16 | 3000 | Rotary | Single layer Multi-layer | 10*2.2*2.45m 40*2.2*2.45m | 90/130KW |

FC-ZMG4-32 | 4000 | Rotary | Single layer Multi-layer | 10*2.2*2.45m 40*2.2*2.45m | 110/175KW |

FC-ZMG5-40 | 5000 | Rotary | Single layer Multi-layer | 10*2.2*2.45m 40*2.2*2.45m | 120/180KW |

FC-ZMG6-48 | 6000 | Rotary | Single layer Multi-layer | 10*2.2*2.45m 40*2.2*2.45m | 130/200KW |

1.Automatic or Semi-Automatic ?

Fully automatic production line,Only putting material and packing manually,other processes pulping,forming,drying,hot pressing and stacking automatically.

2. Output of the machine?

Maximun capacity:6000 pcs/hr.(product size:300*290mm,weight:65-75g/pc)

3. How many workers will be required?

4people/shift to operate the whole system.(One for pulping,one for forming ,one for stacting and one for moving.)

4.What size of the workshop area?

60x 24 (m), height>5m.can be adjusted according to customer's requirement

5. How about the installation?

Supplier should appoint 1-2 engineers to instruct buyer in installstion,test-run and training

6.How about the guarantee and Warranty ?

Life-long service, sustainable supply and upgrade of parts and components,One-year

warranty( three-year warranty for machanical parts and main structure)

7. Leading Time

The leading time is 45 working days.