Профессиональная плоская вулканизирующая машина для ремня и

- Категории: Другое оборудование для обработки резины >>>

- Поставщик: Dongguan,Lixian,Instrument,Scientific,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Professional Flat Vulcanizing Machine for Belt and Tire

Equipment Description:

This series of flat vulcanizing machine is the main equipment that can be used in pressing all kinds of rubber model product and non-model product. In addition, it also can be used in pressing all kinds of thermosetting plastic and foaming rubber and plastic product. With independent actuating unit and electric system, apply button centralized control. Within certain limits, working pressure and heating temperature can be adjusted. This kind of model, can be classified manual operate and semi-automatic operate. The flat vulcanizing machine with the function of a high degree of automation, easy operation,energy conservation and environment protection, and also superior performance.

Technical parameter:

| Model | HZ-7014 |

| Capacity | 10, 20, 30, 50, 80T |

| Temperature range | Normal temperature~300°C |

| Temperature precision | ±2°C |

| Temperature controller | LED button type control mode and PLC touch-screen programmed control mode |

| The method of temperature control | LED button type control temperature or PLC touch-screen programmed control temperature |

| The way of heating | Electric heating |

| Heating up time | Normal temperature~160℃ about 20min |

| Timer | LED display or PLC touch-screen displayer |

| Heating plate size | 350x350mm,500x500mm,1m*1m |

| The number of heating plate layers | Single-layer |

The max.distance between up and lower heating plate | 300,500mm,800mm |

The min.distance between up and lower heating plate | 50mm |

| Exhaust function | Low pressure automatically exhaust 3~10 times per minute (Adjustable) |

| Cylinder stroke | Max 250mm |

| Cylinder speed | 11mm/s |

| Pressure gauge | 0~200kg/sq.cm |

| Dimension | 2*1.5*2.5 (m) |

| Weight | 2.5T |

| Motor power | 4KW |

| Pressure | 380V/60HZ (or 50HZ) |

Main Features:

1. Controlled by PC or manual, performance reliable, high degree of automation. Can automatically identify the wrong command,so avoid the accidence which caused by wrong operation.

2. The preprogrammed process can be locked, the operator can not change without authorization, so that guarantee the quality of pressed product.

3. With the function of timing open mold, automatically exhaust and reinforcing pressure,etc.

4. Optional: Manual operating or Automatic operating mode

5. Electrical heating pressing machine apply digital display (or pointed type) to control temperature, and control and display the heating plate temperature.

Application:

It mainly used in producing vulcanizing parallel adhesive type, such as conveyor belt,driving belt, and pressing rubber products, foamed plastic,thermosetting plastic(bakelite) and other plastic products. It also suitable for O ring,the key products such as cell phone, keyboard,remote-control,sealing washer such as pressure cooker, electric cooker, mechanical accessories for household, food, health and medical treatment. At the same time,this machine alsocan be used in complex silicone and rubber fittings production and process, such as nipple,medical supplies, health product, artware, toy seal, electroconductive rubber, automotive rubber parts, industrial rubber parts,medical silicone product, sport equipment, all kinds of vessels, multilayer product and so on.

Dongguan Lixian Instrument Scientific Co. is one of the leading manufacturers of advanced testing instruments, founded on 2000, located in Dongguan, Guangdong province in China. Lixian Instrument located in Dongguan city, covers an area of 6000 square meters, take the lead in introducing the CNC processing center and NC lathe and other advanced equipment in 2010. Carried on several listed company lab, quality institutions, Tsinghua University, Aeronautics University's project. We have 30000+ buyers in domestic market, succeed in establishing the branch companies and maintenance department in Dongguan, Shanghai, Beijing, Jinjiang, Wuhan, Chongqing, Shenyang, Changsha with showroom. Our products owned CE/ISO/ASTM/ROSH/UL certification, and have exported to more than 70 countries like the USA, Germany, South Korea, Greece, India, Singapore, Brazil, Iraq, Saudi Arabia and so on.

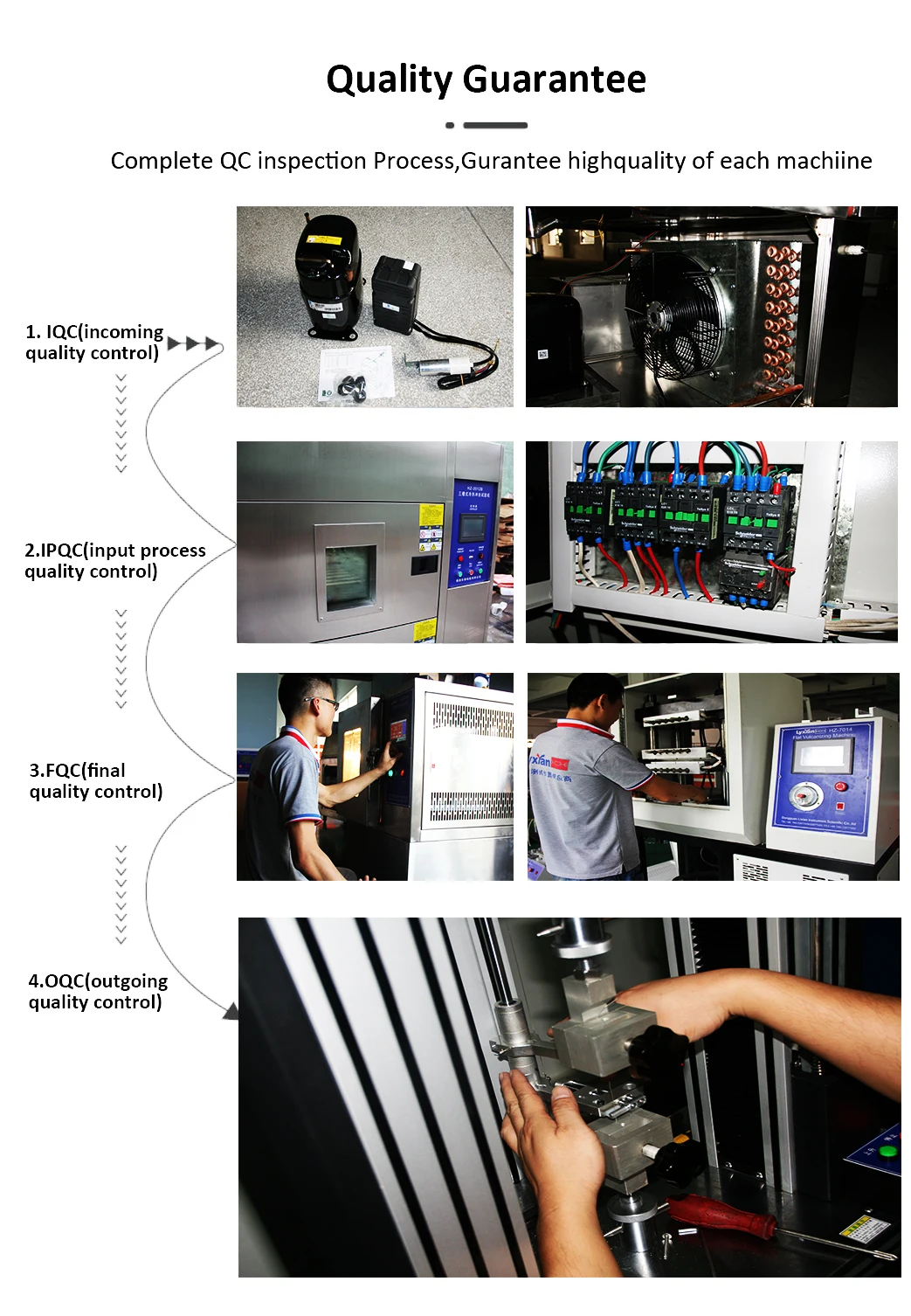

Lixian Instrument owned CE/ISO/ASTM/ROSH/UL certification, and have exported to more than 70 countries like the USA, Germany, South Korea, Greece, India, Singapore, Brazil, Iraq, Saudi Arabia and so on. Lixian Instrument have a professional R & D team and a reliable quality management system, which introduced the CNC processing center and CNC lathe and other advanced equipment in 2010, successfully obtained the CMC measurement certificate and passed ISO 9001 system authentication.

Q1: What is your warranty ?

A: 12 months product warranty, but lifetime for services. Free Non-consumable components will be provided if any performance failure occurs within 12 months, caused by non-human damage.

Q2: How-to video provided ?

A: Yes. If required, our engineers will record a specialized how-to video for you.

Q3: Are your company a trading one or a factory?

A: Yes, we are a manufactured factory & trade (integration).15 years focusing on test instruments field. Six years exporting experience, warmly welcome to visit our plant (factory), we also support OEM and ODM.

Q4: After an order is placed, when to deliver?

A: Generally about 15 days. If we have inventory, we can arrange shipment within 7 days. Please be aware that our production lead times depend on specific items and item quantities.

Q5: What about the after-sales service and product’s quality?

A: 12 months warranty. After the warranty, the professional after-sale service team will provide perfect technical support. And help the customer solve problems encountered while using our product, handles problems and complaints professionally and timely. Each of the instruments must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to install & operate. Engineers would be to go abroad for training and repairing.

Q6: What about the packing of equipment?

A: Covered with air bubble film before put the machine into the standard exporting wooden case, which not only has good shock absorption, impact resistance, heat SSO has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.