Цветной тестер твердости Leeb DTEC DH380 встроенный цветной экран большое функциональное программное обеспечение CE ASTM 600 хранение

- Категории: Physical Measuring Instruments >>>

- Поставщик: Deity,Testing,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

DH380 Portable Hardness Tester is a kind of high-tech grade portable hardness testing instrument,adopting low-power design idea,long life span chargeable NI-MH battery and intelligent USB interface, Which is widely used in various metal material;it equips with built-in mini-printer, which can easily print out testing result on-site; moreover, Large colorful LCD digital screen with 128×64 dot matrix enables it to display not only figure, but also character. Customers who are in need of directly printing data out on-site, and enjoying a digital as well as high-tech testing feel, this is the best choice.

Working Principle:

When the impact body,with a certain weight,impacts against the specimen surface under the action of spring force,leeb hardness comes from the ratio of the impacting velocity(VA) and the rebounding velocity(VB) of the impact body by the moment the spherical testing tip is located at 1mm point from specimen surface.

With principle of electromagnetism,the permanent magnet in the coil of impact device produced an induced voltage, which is in proportion to the impact body velocity.

The leeb hardness values are calculated by the following formula:

HL=1000X(Vb/Va)

Main Application:

- Die cavity of molds

- large colorful true OLED disply,wonderfully show the datas

- Bearings and other parts

- Failure analysis of pressure vessel, steam generator and other equipment

- Heavy work piece

- The installed machinery and permanently assembled parts

- Testing surface of a small hollow space

- Material identification in the warehouse of metallic materials

- Rapid testing in large range and multi-measuring areas for large-scale work piece

- 128×64 dot matrix colorful Large Digital screen, displaying not only figures,but also characters;

- 6 Exchangeable hardness scales: HHRB, HRC, HV, HB, HS, HL, 3 types of strength values, Suitable to measure the hardness of all metallic materials;

- 7 impact devices available for special usage, automatically identify the type of impact devices;

- 600 groups storage capacity, including single measured value, average value, testing data, impact direction, impact times, material and hardness scale etc;

- Built-in mini-printer, enable to print testing result on-site;

- Equips with USB port, standard along with multi-functions(query,saving,statistics) data proceeding software, enable to connect to PC and make further data analysis;

- Humanized user calibration function,also support software calibration;

- Freely set limited hardness value,AUTO alarming when over-limited;

- NI-MH rechargeable battery, continuous working time of no less than 250 hours after full charge(EL off and no printing);

- Auto power off set to save energy;

- Excellent after-sale service system for high quality products---1 years’ guarantee and all life maintenance. Easy to buy and convenient to use.

Testing Range | in Steel:HLD(170-960),HRC(20-68.5),HRB(38.4-99.6),HRA(59.1-85.8),HB(127-651),HV(83-976),HS(32.2-99.5). |

| Indication Error | HLD:±5 HRC:±1 HB:±4 |

Testing Direction | 360° |

Hardness Scale | HL,HB,HRB,HRC,HRA,HV,HS. |

Display Mode | 128×64 Dot Matrix LCD |

Data Memory | 600 groups max.(relative to impact times 32~1) |

Printing Paper | Width:(57.5±0.5)mm;Dia.:30mm |

Battery Pack | 6V NI-MH |

Battery Charger | 9V/1000mA |

Continuous Working Hours | about 250 hours(With backlight off, no printing) |

Communication Interface | USB2.0 |

Dimension | 37x30x12cm(LxWxH) |

Packing Weight | 6KG |

No. | Type of impact device | Hardness value of Leeb standard hardness block | Error of displayed value | Repeatability |

1 | D | 760±30HLD 530±40HLD | ±6 HLD ±10 HLD | 6 HLD 10 HLD |

2 | DC | 760±30HLDC 530±40HLDC | ±6 HLDC ±10 HLDC | 6 HLD 10 HLD |

3 | DL | 878±30HLDL 736±40HLDL | ±12 HLDL | 12 HLDL |

4 | D+15 | 766±30HLD+15 544±40HLD+15 | ±12 HLD+15 | 12 HLD+15 |

5 | G | 590±40HLG 500±40HLG | ±12 HLG | 12 HLG |

6 | E | 725±30HLE 508±40HLE | ±12 HLE | 12 HLE |

7 | C | 822±30HLC 590±40HLC | ±12 HLC | 12 HLC |

Testing Range in Different Materials with Different Impact Devices:

Material | Method | Impact device | |||||

D/DC | D+15 | C | G | E | DL | ||

Steel and cast steel | HRC | 20~68.5 | 19.3~67.9 | 20.0~69.5 | 22.4~70.7 | 20.6~68.2 | |

HRB | 38.4~99.6 | 47.7~99.9 | 37.0~99.9 | ||||

HRA | 59.1~85.8 | 61.7~88.0 | |||||

HB | 127~651 | 80~638 | 80~683 | 90~646 | 83~663 | 81~646 | |

HV | 83~976 | 80~937 | 80~996 | 84~1042 | 80~950 | ||

HS | 32.2~99.5 | 33.3~99.3 | 31.8~102.1 | 35.8~102.6 | 30.6~96.8 | ||

Cold work tool steel | HRC | 20.4~67.1 | 19.8~68.2 | 20.7~68.2 | 22.6~70.2 | ||

HV | 80~898 | 80~935 | 100~941 | 82~1009 | |||

Stainless steel | HRB | 46.5~101.7 | |||||

HB | 85~655 | ||||||

HV | 85~802 | ||||||

Grey cast iron | HRC | ||||||

HB | 93~334 | 92~326 | |||||

HV | |||||||

Nodular cast iron | HRC | ||||||

HB | 131~387 | 127~364 | |||||

HV | |||||||

Cast aluminum alloys | HB | 19~164 | 23~210 | 32~168 | |||

HRB | 23.8~84.6 | 22.7~85.0 | 23.8~85.5 | ||||

BRASS(copper-zinc alloys) | HB | 40~173 | |||||

HRB | 13.5~95.3 | ||||||

BRONZE(copper-aluminum/tin alloys) | HB | 60~290 | |||||

Wrought copper alloys | HB | 45~315 | |||||

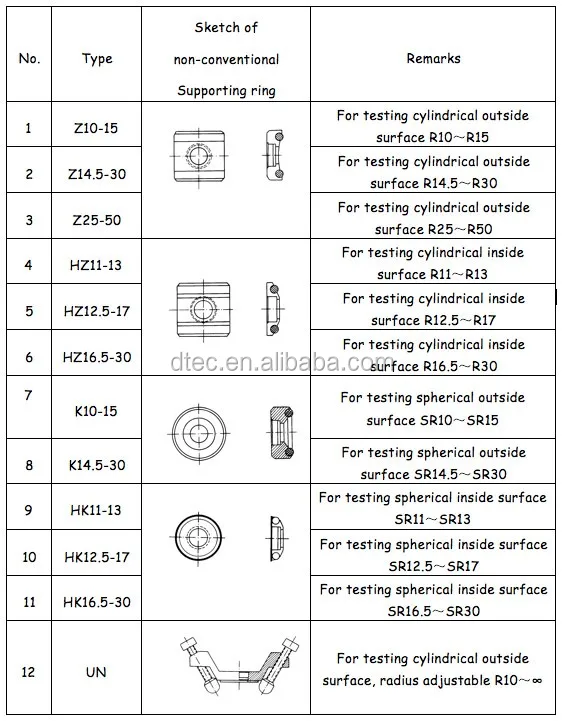

Specification of Supporting Rings:

Standard Packing Accessories:

No. | Items | Qty. | Remarks |

1 | DH380 Main unit with back supporter(stand) | 1 | |

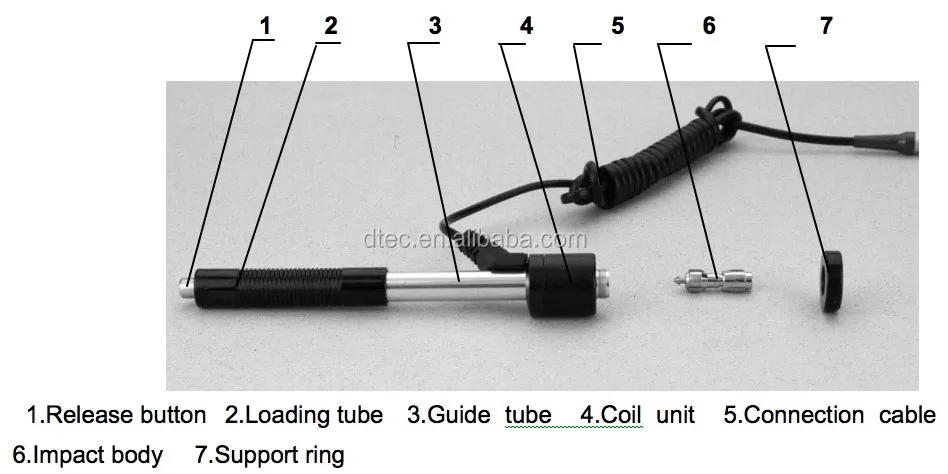

2 | D type impact device | 1 | With cable |

3 | Standard Hardness Block | 1 | |

4 | Cleaning brush (I) | 1 | |

5 | Small support ring | 1 | |

6 | Battery Charger | 1 | 9V 1000mA |

7 | Paper for printing | 1 | |

8 | Manual Book, Warranty Card, Quality Certificate | 1 | |

9 | Data Pro Software | 1 | |

10 | Communication cable | 1 | |

11 | Package Case | 1 |

Optional Accessories:

No. | Items | Notes |

1 | Impact Device | (D/C/G/DC/DL/D+15) |

2 | Impact Body | For all Types: D/C/G/DC/DL/D+15 |

3 | Cable for Impact Device | 1.5M long,3-pin cable |

4 | Supporting Ring | Standard Type and Special Type, 12pcs/set |

5 | Data Processing Software & USB Cable | |

6 | Standard Leeb Hardness Testing Block | 750-850HLD,590-670HLD,490-570HLD,550-630HLG,460-540HLG |

7 | Instrument Case | 35x28x10cm(LxWxH) |

Standard Leeb Hardness Testing Block:

Impact Devices(D/C/DC/DL/D+15/E/G)

Cables for Impact Device(1M in Length):

Impact Body (D/C/DC/DL/D+15/E/G):

Supporting Rings(12 pcs. each set):

Multi-functions(query,saving,statistics,bar graph displaying) data proceeding software.

Every set of our equipement will be carefully tested and double checked steps by steps before being packed and delivery,as we all know that among such fierce international competition,only 100% good quality and stable performance can finally attain the customer's trust.Hence,we will always put the equipment calibraton job in the first place while manufacturing.