2 5 тонн мощность охлаждения цифровое управление портативный кондиционер пятна Бесплатная установка

- Категории: Air Conditioners >>>

- Поставщик: Hangzhou,Qida,Electric,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

APPLICATION SITE AND INSTALLATION OF INDUSTRIAL AIR CONDITIONERS

In the current manufacturing industry, due to continuous production and processing, it is easy to cause the ambient temperature in the production workshop to rise. In addition, under the sultry weather conditions, it is very easy to endanger the health of employees and reduce the manufacturing capacity of the factory. These special circumstances,

Industrial air conditioners must be used.

Comparing industrial air conditioners with central air conditioners, industrial air conditioners do not need to be professionally installed, but they also need to be installed in a suitable application site. It is best to install outdoors. The circulation system can be used to send air to the room while also blowing outdoors. Some of the fresh air to achieve a high-quality indoor air circulation system, both cooling and ensuring the fresh air in the room, if the installation standard allows, it is best to be installed in some fresh air position.

Industrial air-conditioners do not need outdoor air conditioners. 1. It can be assembled outdoors, 2. It can be installed on the wall, 3. It can also be installed on the roof of the factory, all of which can ensure the normal operation of the machine. At the same time, attention must be paid to the assembly and application of parts. 1. The ventilation duct must not be too long. 2. When the ventilation duct is in use, avoid excessive bends in order to ensure that the equipment can be naturally ventilated and ventilated. , Realize the circulation system of indoor air quality.

In short, the use of industrial air-conditioners is an overall design plan. Only when the equipment is installed reasonably can the industrial mobile air-conditioners achieve their maximum efficiency in industrial production.

Industrial air conditioners must be used.

Comparing industrial air conditioners with central air conditioners, industrial air conditioners do not need to be professionally installed, but they also need to be installed in a suitable application site. It is best to install outdoors. The circulation system can be used to send air to the room while also blowing outdoors. Some of the fresh air to achieve a high-quality indoor air circulation system, both cooling and ensuring the fresh air in the room, if the installation standard allows, it is best to be installed in some fresh air position.

Industrial air-conditioners do not need outdoor air conditioners. 1. It can be assembled outdoors, 2. It can be installed on the wall, 3. It can also be installed on the roof of the factory, all of which can ensure the normal operation of the machine. At the same time, attention must be paid to the assembly and application of parts. 1. The ventilation duct must not be too long. 2. When the ventilation duct is in use, avoid excessive bends in order to ensure that the equipment can be naturally ventilated and ventilated. , Realize the circulation system of indoor air quality.

In short, the use of industrial air-conditioners is an overall design plan. Only when the equipment is installed reasonably can the industrial mobile air-conditioners achieve their maximum efficiency in industrial production.

Products Description

7CORE ADVANTAGES:

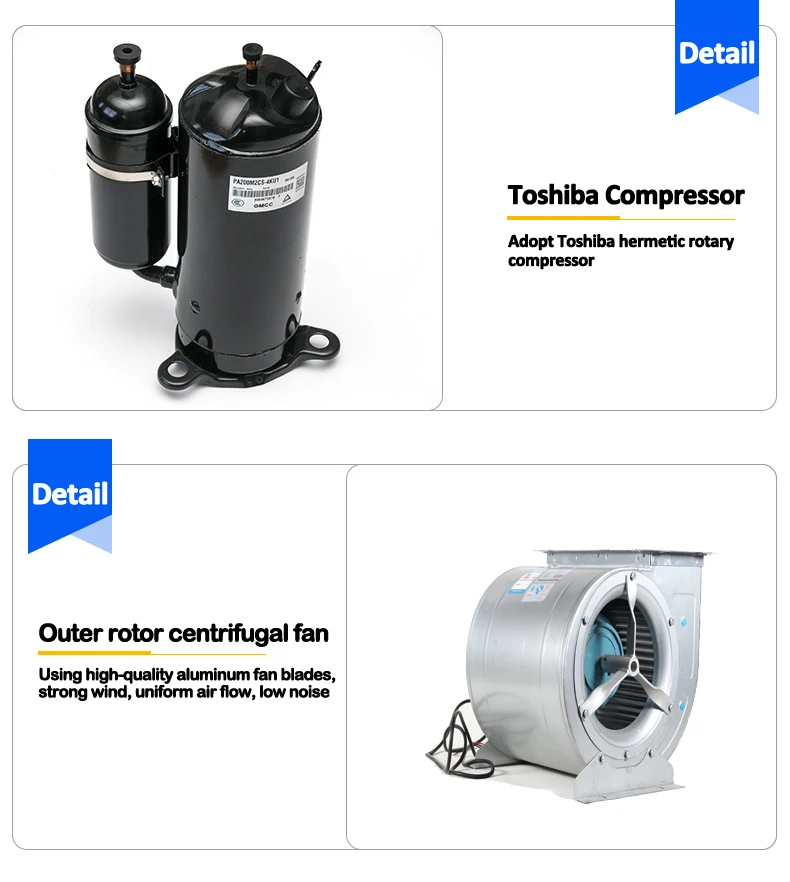

1. Toshiba compressor has stable performance and low failure rate;

2. High-efficiency evaporator and condenser;

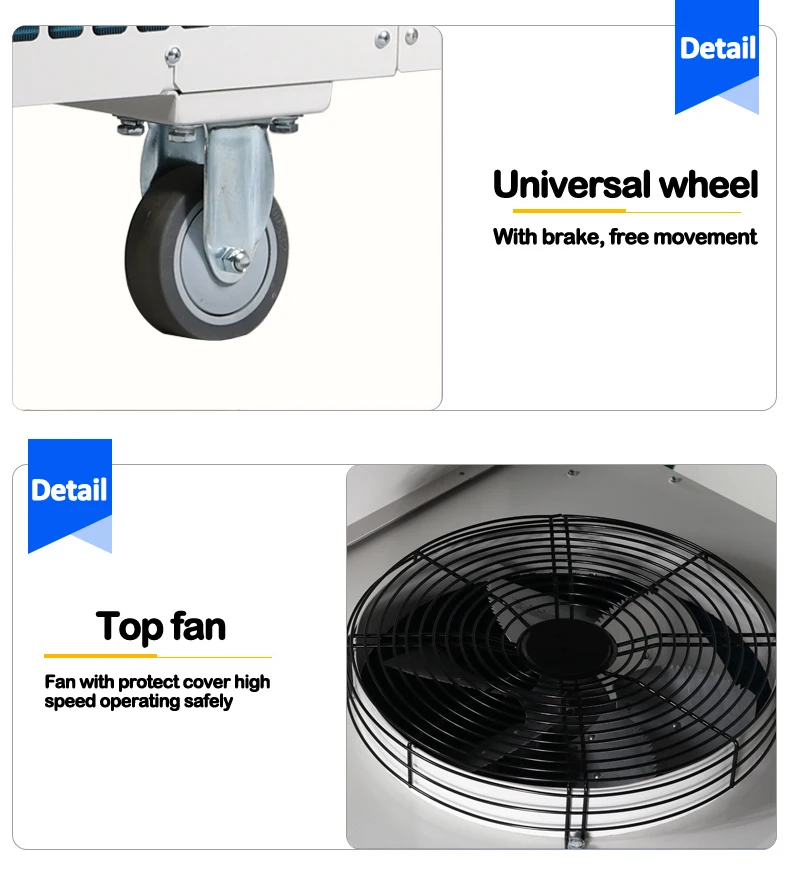

3. Lightweight, flexible, easy to use, and free to move;

4. No need to install, plug and play;

5. Integrated body design, cooling + dehumidification function;

6. High quality, uniform air flow and low noise;

7. Fully automatic control, adjustable humidity

2. High-efficiency evaporator and condenser;

3. Lightweight, flexible, easy to use, and free to move;

4. No need to install, plug and play;

5. Integrated body design, cooling + dehumidification function;

6. High quality, uniform air flow and low noise;

7. Fully automatic control, adjustable humidity

Product Paramenters

MOBLE | QD-85t | |

1 | Power supple | 380VAC/50HZ |

2 | Cooling capacity | 8500W/28900BTU |

3 | Air volume selection | Strong |

4 | Cold air discharge | 1550m3/h |

5 | Warm air discharge | 3900m3/h |

6 | Rated current | 6.5A |

7 | Maximum current | 7.0A |

8 | Power comsamption | 2750W |

9 | Maximum power consumption | 3150W |

10 | Compressor | Fully enclosed rotany |

11 | Condensate treatment method | Ecternal water pipe |

12 | Refrigerant | R22/R410A |

13 | Refrigerant jnjection | 2000g |

14 | Exhaust pressure | 1.8MPa |

15 | Suction pressure | 0.6MPa |

16 | Operating pressure | 2.3MPa |

17 | Use environment | 18℃~45℃ |

18 | Dimensions | 810mm*1050mm*1000mm |

19 | N.W(kg) | 120 |

PRODUCT INTRODUCTION

Spot Coolers are equipped with thermostatic controls, cleanable filters, condensate buckets, cold supply air discharge nozzles and rollers for ease of movement within the facility. For longer term projects, we can provide a condensate pump in place of the condensate bucket.

Meanwhile, spot air cooler system includes everything needed for a single point cooling station that offers a low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. With the turn of a knob , you can select a precise and comfortable temperature in the room. simply roll it in, plug it in, turn it on and set the desired temperature. That’s it !

Meanwhile, spot air cooler system includes everything needed for a single point cooling station that offers a low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. With the turn of a knob , you can select a precise and comfortable temperature in the room. simply roll it in, plug it in, turn it on and set the desired temperature. That’s it !

Case Show

REFRIGERATION AND DEHUMIDIFICATION

Drying technology for swift and sure moisture removal.

Powerful blower creates forceful drying action across the room.

Useful for eliminating odors — and for preventing growth or spread of mold and mildew.

Can be configured for cooling along with drying.

Optional condensate pump lets you send water to the drain.

Simple installation — quick results.

Roll it in, plug it in — attach the duct and turn it on.

High-volume warm air extracts moisture faster than fans or dehumidifiers alone.

Saves time to reduce restoration costs.

Powerful blower creates forceful drying action across the room.

Useful for eliminating odors — and for preventing growth or spread of mold and mildew.

Can be configured for cooling along with drying.

Optional condensate pump lets you send water to the drain.

Simple installation — quick results.

Roll it in, plug it in — attach the duct and turn it on.

High-volume warm air extracts moisture faster than fans or dehumidifiers alone.

Saves time to reduce restoration costs.

Transport

Certifications

FAQ

Q1: Are you manufacturer or trading company?

A1: We are manufacturing factory + trade integration with more than 15years production experience in this field and 5 years exporting experience.

Q2: Can I get samples?

A2:Yes we can provide samples, client need pay the sample fees and express charge.

Q3: Is it possible to make our logo on the product?

A3: OEM and ODM is available, including special design,color, logo, packing etc.

Q4: Can I get any discount?

A4: The price is negotiable, we can offer you discount according to your order quantity.

Q5: What is the process of an order?

A5: Making artwork and design drawing---making samples---samples test---mass production---finished product inspection---packing

Q6: What is your delivery period?

A6: Generally around 10-25days. If we have inventory, we can arrange shipment within 3days.(Only need time to change the plug and do the pre-shipment test) Also, production lead time depends on specific items and quantity.

Q7: What about the warranty-after sales service?

A7: We offer 1 year warranty for our machines.We have after-sales department for 24hours consultation service.

A1: We are manufacturing factory + trade integration with more than 15years production experience in this field and 5 years exporting experience.

Q2: Can I get samples?

A2:Yes we can provide samples, client need pay the sample fees and express charge.

Q3: Is it possible to make our logo on the product?

A3: OEM and ODM is available, including special design,color, logo, packing etc.

Q4: Can I get any discount?

A4: The price is negotiable, we can offer you discount according to your order quantity.

Q5: What is the process of an order?

A5: Making artwork and design drawing---making samples---samples test---mass production---finished product inspection---packing

Q6: What is your delivery period?

A6: Generally around 10-25days. If we have inventory, we can arrange shipment within 3days.(Only need time to change the plug and do the pre-shipment test) Also, production lead time depends on specific items and quantity.

Q7: What about the warranty-after sales service?

A7: We offer 1 year warranty for our machines.We have after-sales department for 24hours consultation service.