1000 пакетов в час роботизированная машина для укладки

- Категории: Tobacco Processing Machinery >>>

- Поставщик: Zaozhuang,Fuliang,Packaging,Machinery,Co.,Ltd.,[Shandong,China]Zaozhuang

Поделиться:

Описание и отзывы

Характеристики

|

PACKING CAPACITY |

600-1200 bags/hour (depending upon the material) |

|

|

FILL MODE |

1-2 time/1 bag filled (Customized) |

|

|

PACKING MATERIALS |

Granule/Flakes/Powders/Lumps/Pellet |

|

|

BAG TYPE |

Kraft Paper bags |

|

|

PP Woven bags |

||

|

Plastic bags (thickness 0.2mm) |

||

|

BAG SIZE |

LONG (mm) |

750-950(Customized) |

|

WIDTH (mm) |

400-520(Customized) |

|

|

BOTTOM WIDTH (mm) |

0-75(Customized) |

|

|

MATERIAL FILLING DEVICE |

Net weighing. Double type. Dosing system |

|

|

ACCURACY |

±0.2% (It changes with physical properties of materials and its capacities) |

|

|

SEALING MODE |

Paper bags: Stitching/Hear seal tape/Crepe tape |

|

|

Woven bags: Folding/Stitch |

||

|

Plastic bags: Heat |

||

|

AIR CONSUMPTION |

2,000 NL/min |

|

|

RATED POWER |

8.9 kVA |

|

|

WEIGHT |

3,000 kg (Referance) |

|

|

DIMENSIONS |

(Customized) |

|

Applications:

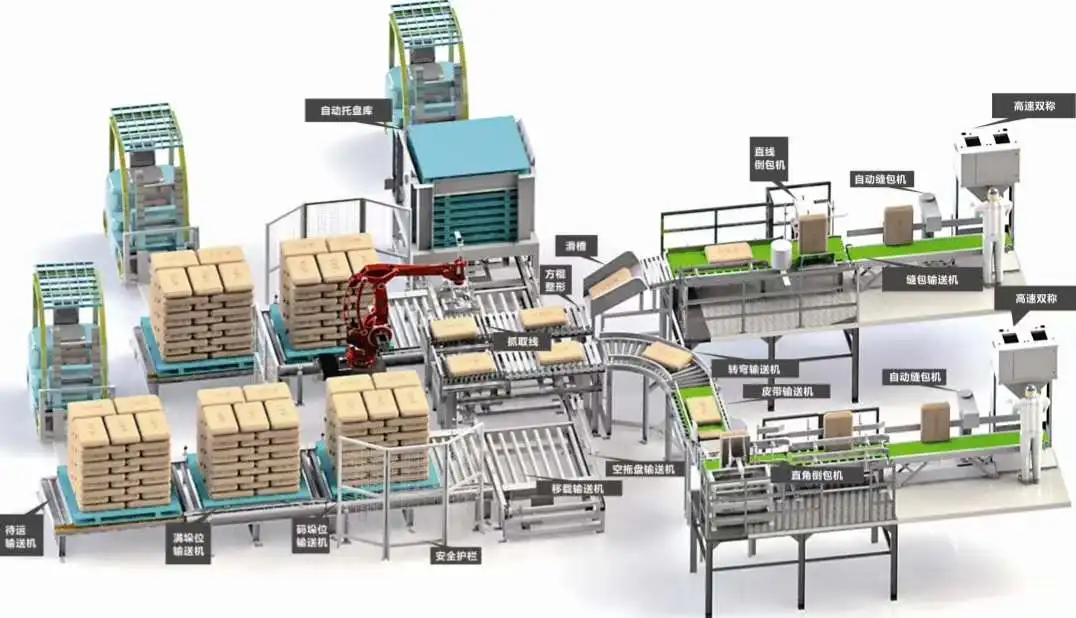

It is Fully automatic protein powder Bagging system with robot Palletizer quantitative in industries such as chemistry, fertilizer, grain, food, feed, medicine, construction materials industry, etc.

LCS-MZDP Series is a fully automatic packing machine for open-mouth bags with high degree. It can be used for packaging of bags with various materials, particularly for woven bags with plastic coating. The packaging lines have been well received in Thailand SIAM Company, one of the largest rice processing factories in the world. The packaging line is composed if automatic weighing packaging machine, automatic packaging machine, mesh-belt conveyor, bag feeding machine, reversing bag flattener and control system, etc.

A whole set of processing procedures including materials transmission, weighing, filling, packaging, bag flattening, sealing , sewing and conveying can be finished by the machines. Our machines can be made to order and designed according to customer’s requirement.

Display:

Main Components:

1. Automatic quantity-fixed balance

2.Automatic bag-supply section

3. Optional section such as air compressor

4.Automatic bag-clamped section

5. Automatic belt conveyor

6.Automatic sewing / sealing machine

7. Automatic bag-backwards section

8.Electrical instrument control cabinet

Characteristics:

Picking bag, feeding bag, filling material, weighing in , sewing / sealing bag, bag-backwards and bag transmission are finished completely automatically.

Adopting PLC to guarantee the reliability of control

Adopting high-precision transducer and intelligent instrument to guarantee the accuracy and speed of weight

Adopting touch screen with trouble display and help system for easy operation.

Adopting imported pneumatic components features compact structure, reliable performance and convenient maintenance.

The sewing / sealing machine is an imported machine.

Package:package:

contact me

contact me

Q1: How could I choose the right packing machine?

A: We have various item of packing machine to suit for pack different materials(products), just let me know your

product and requirement, we will choose the suitable item and make a drawing for you to confirm. Also your customize design are availbale, we have more than 10 person engineers team and R&D team.

Q2: What is your terms of delivery?

A: EXW, FOB, CFR, CIF

Q3: How about your delivery time?

A: Generally, it will take 30 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q5: How do you make our business long-term and good relationship?

A: 1, We keep good quality and competitive price to ensure our customers benefit

2, We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.