Высокоточный мини-лазерный сварочный аппарат для ювелирных изделий золота серебра меди и

- Категории: Laser Welders >>>

- Поставщик: Jinan,GoodCut,CNC,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

High Accuracy Mini Laser Welding Machine for Jewelry Gold Silver Copper and Teeth Braces

Max. laser power | 200W | |||

Laser wave-length | 1064nm | |||

Single pulse energy | 90J /110J | |||

Pulse width | 0.3 - 20ms | |||

Welding frequency | 0.5 - 100Hz | |||

Laser Spot Dia: | 0.2-3.0mm | |||

Control system | micro-computer | |||

Power consumed | 6KW | |||

Electrical source | 220V10%/60Hz or 50Hz/30A | |||

Cooling system | Wind Cooling Or Water Cooling | |||

This hot sale 100w 200w spot laser welding machine jewelry portable laser soldering machine for gold and silver adopts imported ceramic and metal reflecting cavity, pulse xenon lamp pumped to output 1064nm laser, mainly for welding jewelry thin materials, precision parts, can realize spot welding, butt welding, lap welding, sealing welding, high depth width ratio of weld width, Small heat influence area, low distortion, welding speed, welding seam smooth, beautiful welding gap, after welding the appearance is without processing or simply processing, welding quality is high, pore-free, can be controlled accurately, the focal spot size is small, high positioning accuracy.

01. Energy, pulse width, frequency and faculae can be adjusted within a wide range to achieve different welding effects.

02. The parameters are adjusted by the control rod in the sealed cavity, simple and efficient .

03. Ceramic focusing cavity imported from the U.K. is employed, corrosion resistant, high temperature resistant, efficient in optical/electrical conversion.

04. The focusing cavity's service lifespan is 8 to 10 years, and the service lifespan of the Xenon lamp is over 8 million times.

05. World-leading automatic light shielding system is employed to remove stimulation of light on eyes during operation.

06. 24-hour continuous operation, with stable operating performance and maintenance-free within 10,000 hours. Personalized design in compliance with ergonomics principles.

Welding Material

Platinum, Karat Gold, Silver, Titanium, Stainless Steel, Cooper, Aluminum, other metal and alloy.

Application Area

Widely applicable to all kinds of micro parts of precision welding, such as: Jewelry, electronics, Dental,watches, military.

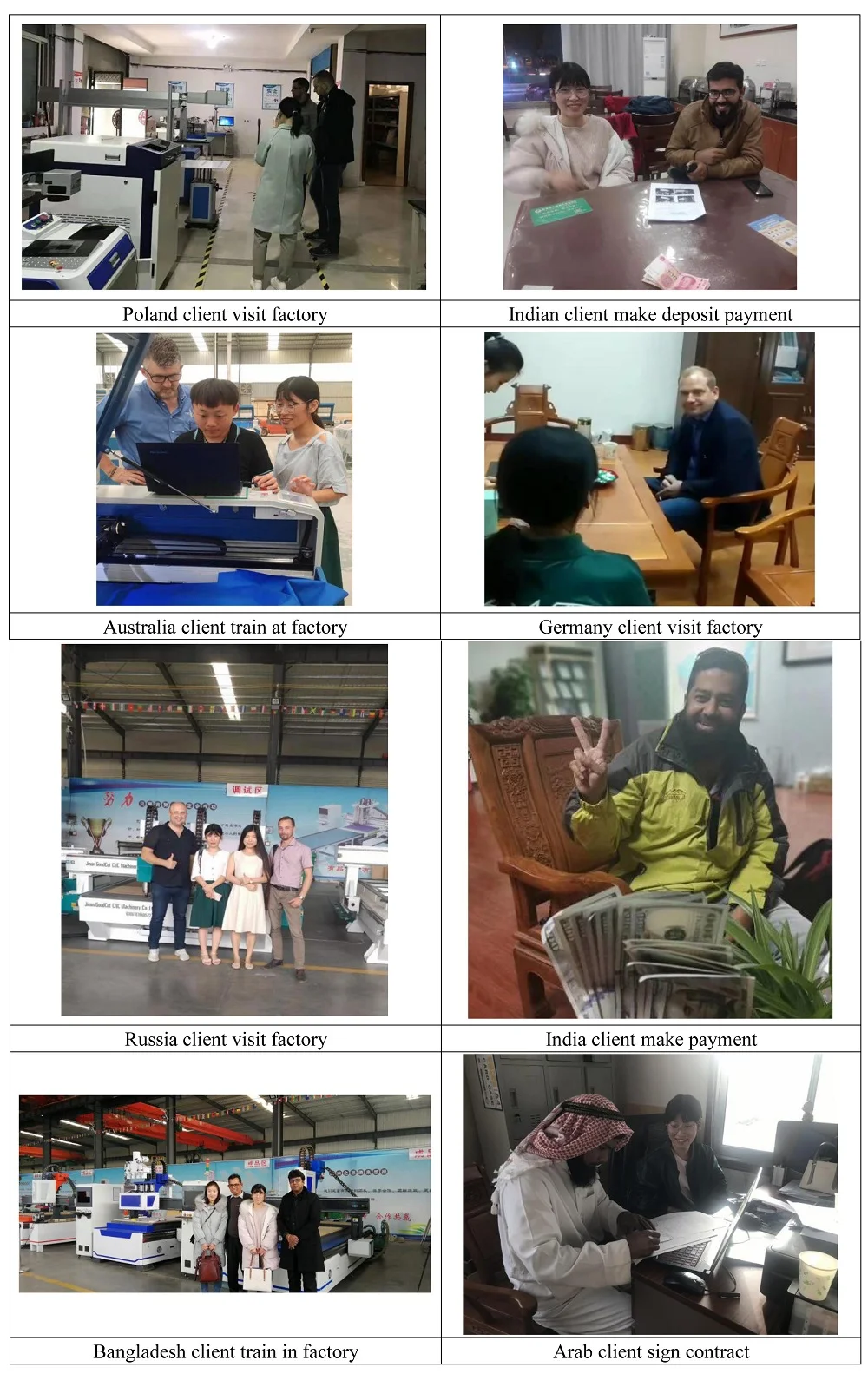

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2. Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 500 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching to eliminate customer worries.

Jinan GoodCut CNC Machinery Co.,Ltd. GoodCut has Purchasing department, The design department, The production department, Quality inspection department, packaging and transportation department, The sales department, After sales service department. We can offer highest quality machine, and competitive price.

Mainly manufacture and sale cnc router, laser engraving, marking, cutting machine, wood lathe machine, fiber cutting machine, plasma cutting machine, 3D scanner etc.