410L различные виды горячей продажи интенсивный силиконовый резиновый смеситель внутренний Банбери с тангенциальным

- Категории: Internal Mixers >>>

- Поставщик: Zhangjiagang,Lanhang,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Why Choose Intermeshing 410L Banbury Mixer Products from Lanhang

1. We're founded in 1992, with more than 20 years' professional experience

2. Fourtune global 500 companies' supplier, such as Dow Corning, Shin Etsu, Blue Star, Wacke, Momentive, etc.

3. Overseas service center available (in Europe, Japan, Dubai, etc.)

4. International CE, SGS, IAF, CNAS certification

5. National high-tech enterprise / products

6. We own various National Patent for Inventions for rubber & plastic machinery

7. ISO9001:2008 management

Main Parameters of Our Intermeshing 410L Banbury Mixer

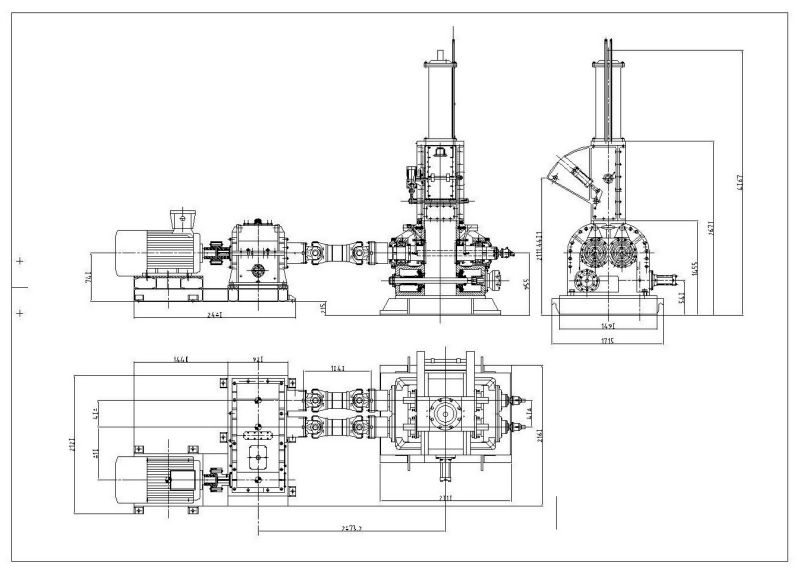

Model | LX-75L | LX-100L | LX-120L | LX-160L | LX-255L | LX-270L | LX-410L |

Chamber Volume (L) | 75 | 100 | 120 | 160 | 255 | 270 | 410 |

Filling Coefficient | 0.75 | ||||||

Rotor Type | Tangential | ||||||

Rotor Speed (r/min) | 40 | 40 | 40 | 40 | 4-40 6-60 | 4-40 | 6-60 |

Rotor Speed Ratio | 1:1.17 | ||||||

Max. Capacity (T/H) | 1.25 | 1.6 | 1.95 | 2.64 | 4.6 | 4.6 | 7.4 |

Motor Power (Kw) | 160 | 220 | 310 | 355 | 900 1500 | 1250 | 2x1250 |

Dimension (m) | 5.8x2.6x4.2 | 6.6x2.8x4.4 | 7.0x3.0x4.9 | 8.0x3.3x5.3 | 8.2x3.9x5.6 | 8.7x4.3x6.1 | 10.8x4.9x7.0 |

Weight (T) | 20 | 24 | 26 | 28 | 55 | 55 | 76 |

Application of Our 410L Banbury Mixer

This intensive mixer has a wide range of applications, including in mixing and refining Raw materials, such as raw rubber, synthetic rubber, resin, asphalt, cellulose, PVC or EVA into even mixed stock. The body and structure of this machine are strong and durable, making it suitable for heavy-duty Rubber & Plastic mixing and refining operations.

Features of 410L Banbury Mixer

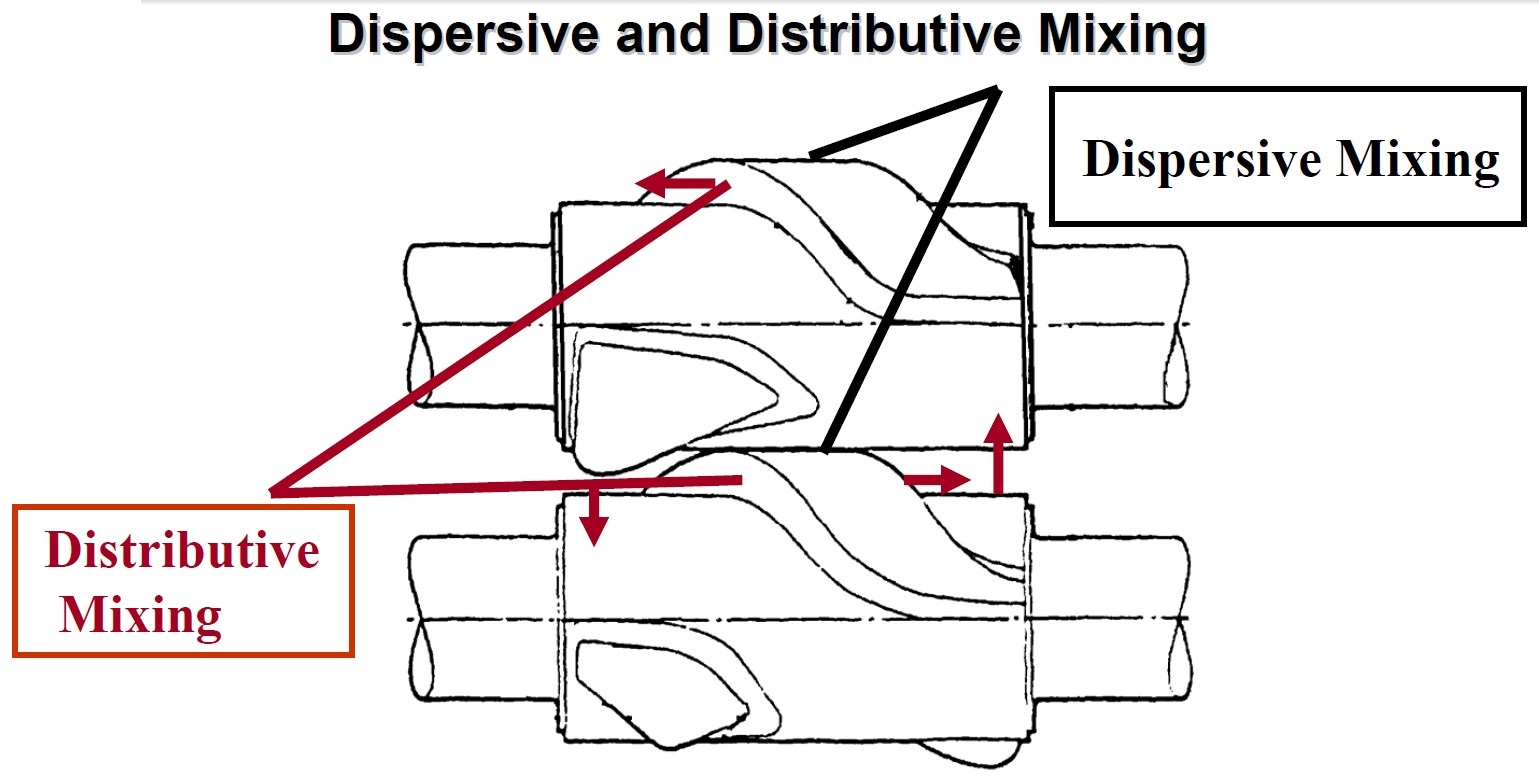

1. Intermeshing or tangential rotor

2. Rotors, mixing chamber, harmmer and parts which contacts with the material are overlayed with 5mm wear-resistant alloy (up to 50HRC)

3. Pneumatic or hydraulic type top mounted ram is optional

4. Falling type floating weight which is driven by gear and hydraulic oil tank with good sealing performance.

5. Inverted AC motor or variable speed DC motor is optional

6. Drop / side door discharging

7. Copper-ring and hydraulic sealing

8. 2-wing, 4-wing, 6-wing are available

9. Excellent dispersing effect

10. Best mixing rotor and chamber to guarantee 100% mixing effect

11. LG brand electrical parts, Mitsubishi brand PLC, ABB motor

12. Low noise, safe mixing

13. Maintenance friendly and long-life service

Description of 410L Banbury Mixer

The Banbury Mixer, which is invented by Fernley H. Banbury, was introduced to the rubber manufacturing industry in 1917. The machine is called a compounder, mixer, or blender. It mixes components together that do not readily blend but require a lot of energy to become homogeneous. The mixer is a batch operation and is used to blend rubber and plastics or many different materials with additives.

Working Principle of 410L Banbury Mixer

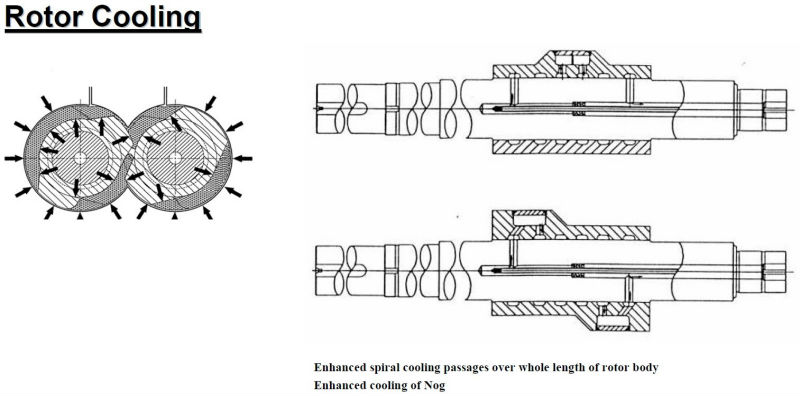

The materials to be blended are introduced through a hopper. A ram pushes the materials into the mixing chamber. Two counter-rotating rotors provide the mixing action, much like double dough hooks. The blended batch is discharged through an opening in the bottom of the mixing chamber to the next processing step. Improvements made over the years include many design changes to enable easier operation and maintenance.

Heat transfer is closely controlled in the modern Banbury Mixer. The rotors generate a lot of friction with the material, so mixing is generally an exothermic process, giving off heat to the environment. Some mixes absorb heat and become cooler, however. In many processing operations, heat may be added to the system.

Internal pressure is also controllable, and many mixing operations occur under increased pressures and temperatures. This capability is necessary for the mixer to act as a reactor chamber in the manufacture of many polymers. Compounding of rubbers or rubber recycling is often spoken of as mastication and softening. While those terms imply the first steps of human digestion, the rubber is usually not chemically changed.

Our Certificates for 400L Banbury Mixer

Wood Pallet & Film Wrap ( 410L Banbury Mixer )

400L Banbury Mixer

1. One year warranty

2. Engineers available to service machinery overseas (installation, debugging, commissioning and maintenance.)

3. Overseas service center available (in Europe, Japan, Dubai, etc.)

4. Life-long technical support