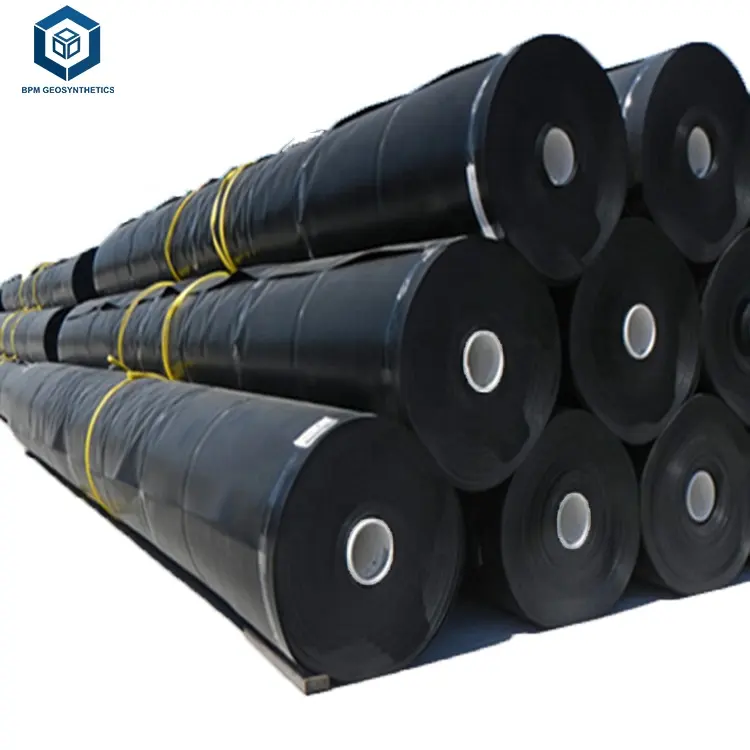

Astm Hdpe Geomembrane Pond Liner Fish Tank 1.5mm

- Категории: Earthwork Products >>>

- Поставщик: Taian,Huasu,Engineering,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

HDPE SMOOTH GEOMEMBRANE sheet 1-2

| Properties | TEST METHOD | UNIT ENGLISH(METRIC) | 20mil HD | 30mil HD | 40mil HD | 50mil HD |

| Thickness | ASTM D 5199 | mil(mm) | 20(0.50mm) | 30(0.750) | 40(1.00) | 50(1.25) |

| Density | ASTM D 1505 | g/cm3 | 0.940 | 0.940 | 0.940 | 0.940 |

| Tensile Properties(Each Direction) | ASTM D 6693,Type IV | |||||

| Strength at break | Dumbell,2 ipm | lb/in-width(N/mm) | 96(17) | 114(20) | 152(27) | 188(33) |

| Strength at yield | lb/in-width(N/mm) | 51(9) | 63(11) | 84(15) | 102(18) | |

| Elongation at Break | G.L.2.0in(50mm) | % | 700 | 700 | 700 | 700 |

| Elongation at Yield | G.L.1.3in(33mm) | % | 12 | 12 | 12 | 12 |

| Tear Resistance | ASTM D 1004 | lb(N) | 18(80) | 21(93) | 28(125) | 35(156) |

| Puncture Resistance | ASTM D 4833 | lb(N) | 45(200) | 54(240) | 72(320) | 90(400) |

| Carbon Black Content | ASTM D 1603*4218 | %(range) | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

| Carbon Black Dispersion | ASTM D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | |

| Notched Constant Tensile Load | ASTM D 5397,Appendix | hr | 300 | 300 | 300 | 300 |

| Oxidative Induction Time | ASTM D 3895,200℃;O2,1atm | mins | >100 | >100 | >100 | >100 |

| TYPICAL ROLL DIMENSIONS | ||||||

| Roll Length | ft(m) | 1,120(341) | 1,120(341) | 870(265) | 720(219) | |

| Roll Width | ft(m) | 22.5(6.86) | 22.5(6.86) | 22.5(6.86) | 22.5(6.86) | |

HDPE SMOOTH GEOMEMBRANE sheet 2-2

| Properties | TEST METHOD | UNIT ENGLISH(METRIC) | 60mil HD | 80mil HD | 100mil HD | 120mil HD |

| Thickness | ASTM D 5199 | mil(mm) | 60(1.50) | 80(2.00) | 100(2.50) | 120(3.00) |

| Density | ASTM D 1505 | g/cm3 | 0.940 | 0.940 | 0.940 | 0.940 |

| Tensile Properties(Each Direction) | ASTM D 6693,Type IV | |||||

| Strength at break | Dumbell,2 ipm | lb/in-width(N/mm) | 228(40) | 304(53) | 380(67) | 457(80) |

| Strength at yield | lb/in-width(N/mm) | 126(22) | 168(29) | 210(37) | 251(44) | |

| Elongation at Break | G.L.2.0in(50mm) | % | 700 | 700 | 700 | 700 |

| Elongation at Yield | G.L.1.3in(33mm) | % | 12 | 12 | 12 | 12 |

| Tear Resistance | ASTM D 1004 | lb(N) | 42(187) | 56(249) | 70(311) | 84(374) |

| Puncture Resistance | ASTM D 4833 | lb(N) | 108(480) | 144(640) | 180(800) | 215(960) |

| Carbon Black Content | ASTM D 1603*4218 | %(range) | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

| Carbon Black Dispersion | ASTM D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | |

| Notched Constant Tensile Load | ASTM D 5397,Appendix | hr | 300 | 300 | 300 | 300 |

| Oxidative Induction Time | ASTM D 3895,200℃;O2,1atm | mins | >100 | >100 | >100 | >100 |

| TYPICAL ROLL DIMENSIONS | ||||||

| Roll Length | ft(m) | 560(171) | 430(131) | 340(104) | 164(50) | |

| Roll Width | ft(m) | 22.5(6.86) | 22.5(6.86) | 22.5(6.86) | 22.5(6.86) | |

| Roll Area | ft2(m2) | 12,600(1,171) | 9,675(899) | 7,650(711) | 3,690(342) | |

MTTVS The HDPE smooth geomembrane is blow-molded by adding a certain proportion of carbon black masterbatch, anti-aging agent, ultraviolet absorber, stabilizer, etc. to high-density polyethylene resin.

Features of MTTVS HDPE smooth geomembrane

- Smaller proportion

- Strong extensibility

- High adaptability to deformation

- preservative

- Low temperature resistance

- Good frost resistance

It is suitable for various reinforced anti-seepage projects such as water conservancy, transportation, tunnels, airports, metallurgical tailings, garbage disposal sites, and roof anti-seepage projects.

Q1:Are you trading company or manufacturer?

A1:We are manufacturer.So wo have a lower price than trading company.and guaranteed quality.

Q2:Where is your company?

A2:Taian shandong province, China. Welcome to our company.

Q3:What is your delivery time?

A3:Generally in stock, the delivery period is within 1-3 days. If customized, the delivery period is 3-10 days according to the order quantity.

Q4:What is your payment method?

A4:T/T, Western Union, L/C,PAYPAL...

Q5:Do you provid samples?Is it free or extra?

A5:Yes, we can offer the PP plastic geogrid sample for free charge but do not pay the cost of freigh.

Q6:What is your terms of payment?

A6:Payment<=1000USD,100% in advance.Payment>=1000USD, 30%T/T in advance, balance before shippment. If you have another question, please to contact me.