Сертифицированный 9001 ISO 20 лет изготовленный на заказ металлический корпус шкафа из

- Категории: Computer Hardware & Software >>>

- Поставщик: Shenzhen,Jialongfu,Technology,Co.,Ltd.Shenzhen,Ltd.

Поделиться:

Описание и отзывы

Характеристики

15 years experience manufacturer---OEM/ODM and design service!!!

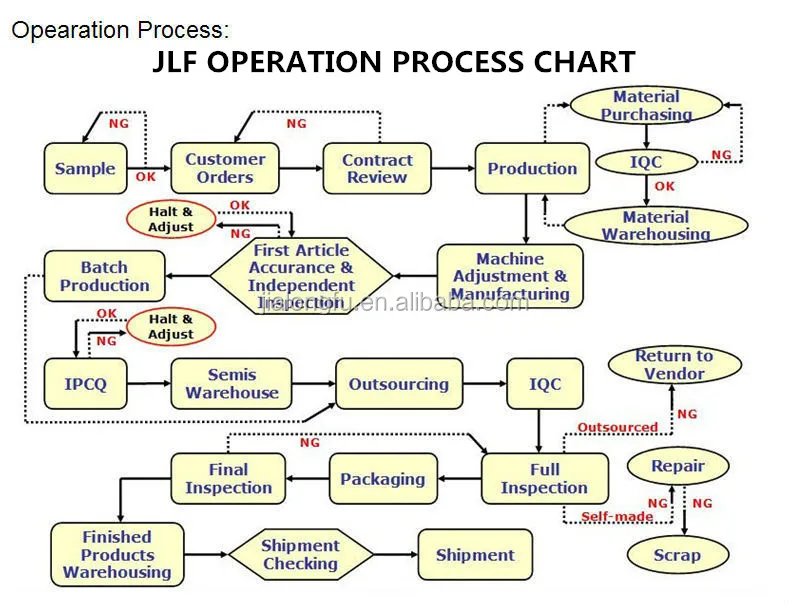

-One-stop service from raw material supply, sheet metal profiling, steel structure fabrication, surface

treatment, warehousing to logistics;

-Qualified workers and experienced management team; 3,000sqm workshops

Products Photos:

Our Machine:

What We Do:

Customized metal products made from steel sheet, steel tube and steel wire, as well as stainless steel and aluminium, mainly by processes of cutting, bending, stamping and welding. We have very wide metal products range, such as cloth display rack, display stand, metal stairs, metal decoration fixtures, metal case, various metal parts, etc.

Step to Samples:

Step1: provide your drawing and requirements to us.

Step2: we make quotation.

Step3: negotiation and confirm product details.

Step4: confirm sample cost, freight and delivery.

Note:

Sample unit cost will be 3 times based on the final quotation.

Because samples are customized, it takes us more labor costs than mass production.

Usually sample delivery time is around 10 to 20days.(up to the products)

Step5: provide PI to you, you make payment accordingly.

Step6: we start production, and keep you informed updated news.

Step7: send you details and photos when qualified sample is finished.

Step8: make shipment after above information is confirmed.

Trade & Service:

DELIVERY TIME & SHIPMENT:

Delivery time: 20 to 40 days (up to products and order qty.)

Shipment: According to your needs, we can arrange shipment by sea, air and courier to your ports. Also we can deliver goods to other cities of China.

PRICE TERM AND PAYMENTMETHOD:

EXW, FOB, CNF, CIF

T/T, L/C at sight

Note: 30% deposit is required before production, because we do customized products for clients, we unable to sell them to others, have to reduce our risk. Hope you can understand.

AFTER SERVICE:

Provide technical support during your assembling, installing and reprocessing.

Refund and rework policy for quality problem.

About JLF:

JLF Technology Limited is a Hongkong owned enterprise which is located in Ban’an District, Shenzhen, China, Covers an area of totally 2919 square meters, and our new workshops will be finished soon in the end of this year which will be 6000 square meters.

Our factory is specialized in custom manufacturing various kinds of machinery parts with more than 15 years experience, and our main business areas are :

1.) Die Casting Parts

2.) CNC Machining Parts

3.) Sheet metal fabrication

4.) Welding parts

In Shenzhen and Hongkong, we respectively have a research and development team, sales team and production team, with many customers around the global.

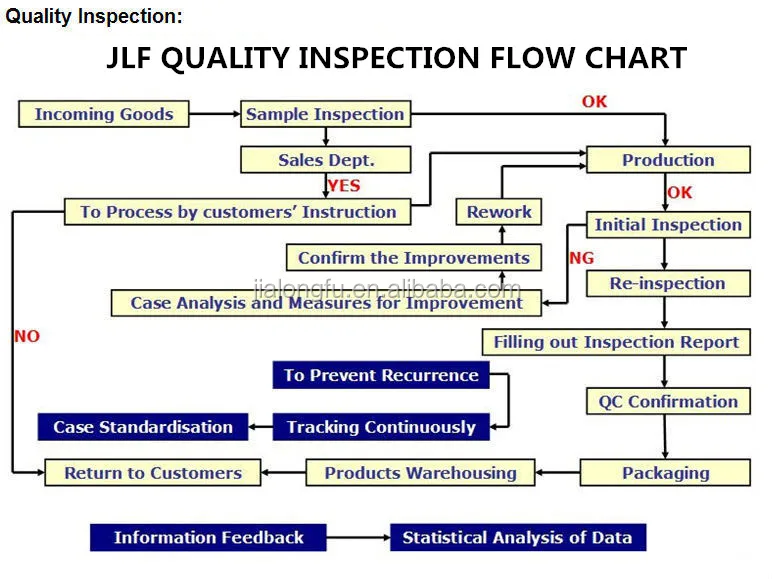

Our factory is well equipped to fit your outsourcing needs, with wide range, rich experience and high work sense of our QC , we can reduce every unnecessary cost for you.

Our success is determined by the satisfaction and confidence of our customers in what we do and how well we do it.

PICTURE SHOW!!!

Universal Joint, Whipstock

1: Specialized in various metal part and mould part producing, CNC Machining, and Metal Stamping, Forging and Casting

2: All international standard materials can be available, carbon steel, alloy steel, stainless steel, brass, aluminum and plastic etc

3: All kinds of finish treatments can be available, like power coating, hard anodizing, zinc plated, plating, oxidation, blasting, painting, anodizing, heat treatment etc

4: We have good cooperation companies, we make good use of outsourcing some factories and equipment, like heat treatment, large boring machine etc, so we can digest large order

5: Sample is ok for confirmation before mass production

6: Firstly, check the raw material before massive production

Strict Tolerance Control !!!

7: During production, technicians self-check and Engineer spot check to assure the good quality.

8: QC inspect after products finished

9: Before package, we will choose the best way to avoid the unnecessary damages during transportation

10: Salesmen who are trained the technical know-how spot check before shipping

11: Main equipment: CNC lathe, automatic lathe, hand lathe grinder, thread rolling machine, tapping drilling machine, boring machine and CNC machining center etc

12: Advanced measuring & testing equipment: Projecting apparatus, roughness tester, hardness tester, concentricity tester etc

13: We offer the total solution to customers’ idea with in-house production/assembly & outsourcing program

14: We offer the engineer consultation to your design for production improvement and cost saving

15: Inspection report and material test certificates are available upon request.

16: IPQC inspect each during every step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate measuring machine(CMM), etc.

17: Can meet DIN, JIS, ASTM, AISI, BS, GB standard

18: We insist Honesty is Time, Conscience is Quality

CNC CUSTOM PRECISION MACHINING PARTS

Advanced Manufacturing Facilities