PA нейлоновый Стекловолоконный двойной винтовой гранулирующий экструдер для машины по производству

- Категории: Plastic Granulators >>>

- Поставщик: Nanjing,Gs-Mach,Extrusion,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

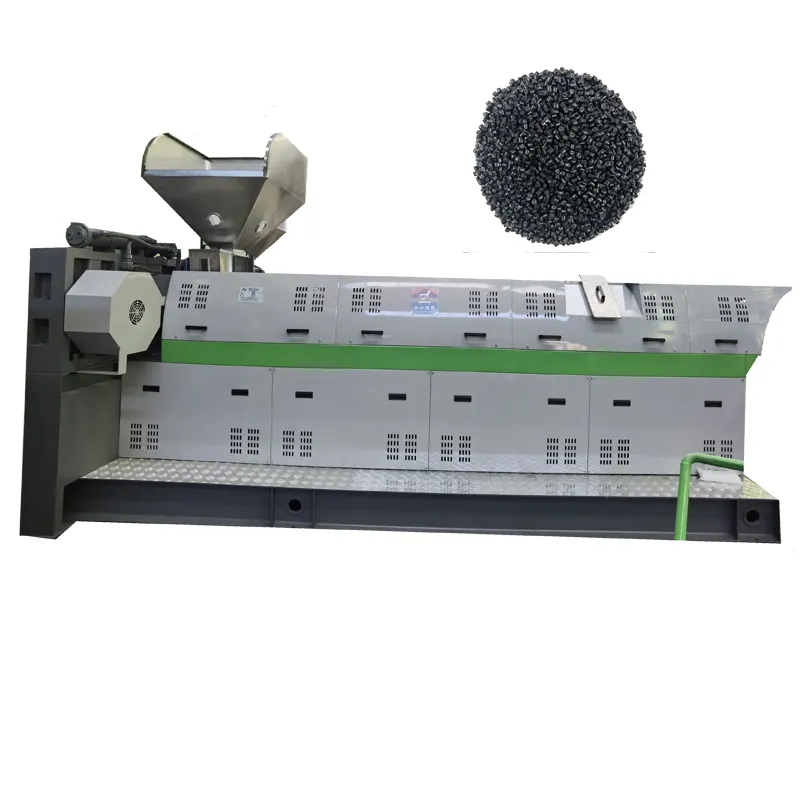

PA Nylon Glass Fiber Twin Screw Pelletizing Extruder for Plastic Granules Making Machine

Detailed Images

Model | Machine | Quantity |

1. | High Speed Mixer | 1 Set |

2. | Spiral Load Feeder | 1 Set |

3. | Twin Screw Extruder Machine | 1 Set |

4. | Electrical Control System | 1 Set |

5. | Pelletizing System | 1 Set |

Water Strand

Underwater

Air Cooling Strand

Water Ring

1.coupling can effectively protect the reduction gearbox from extrusion unit overload dangers.

2.water-cooling system and lubrication systems are all real-time online monitoring.

3.drive ead pressure and melt temperature are all equipped with alarm systems.

Application Area

1.Fiber reinforcement: glass fiber, carbon fiber reinforced PP, PA, PBT, ABS, AS, PC, POM, PPS, PET, PPO, PSF, LCP, etc.

2.Ploymer blending: bleding of PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+SBS, etc.

3.Incorporation of fillers: CaCO3, Tale, TiO2, carbon black filled PE, PP, or EVA etc.

4.Cable Compounds: cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, MDPE; radiation-crosslinkable compounds, optical fiber protection compounds, heat-shrinkable polymer compounds.

5.Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes ,tobacco filter compounds, etc

6.High Concentration Color Masterbatches: PE, ABS, PS, EVA, PET, PP etc. With high concentration of pigments and other procrssing aids.

7.Masterbatches with Flame Retardants:PP, PA, ABS, EVA, PBT etc.with flame retardants and other additives.

8.Special Functional Masterbatches :Masterbatches with anti-static, anti-abcteria, or other special functional fillers.

9.Masterbatches for Degradable Polymers: PP, PE, PS etc. Blended with high concentration of starch and other processing aids.

Company Profile

FAQ

A:Are you a manufacturer, can we visit at your factory?

We are a manufacturer, our factory is at maanshan city, glad to invite you have a visit at our factory.

We are a manufacturer, our factory is at maanshan city, glad to invite you have a visit at our factory.

B:Why choose us?

(1)We have complete system of designing of extrusion equipment

(2)We can provide perfect extrusion management solutions and extrusion equipment

(3)We could make you in a leading position in the industry

(1)We have complete system of designing of extrusion equipment

(2)We can provide perfect extrusion management solutions and extrusion equipment

(3)We could make you in a leading position in the industry

C:What's the payment method?

T/T, L/C, Western union

T/T, L/C, Western union

D:Can I see your machine operating in your factory?

Yes, you can bring some materials to our factory test-run the equipment, we can also send other customers' operating videos for your reference

Yes, you can bring some materials to our factory test-run the equipment, we can also send other customers' operating videos for your reference

E:How long of the warranty time?

Our warranty period is 1 year

Our warranty period is 1 year

F:After-sales service:

Field installation, commissioning and training ;

Field maintenance and repair service ;

Video/Online technical support.

Field installation, commissioning and training ;

Field maintenance and repair service ;

Video/Online technical support.

Mobile/Whatsapp/Wechat: +8618151621522

Email: sales2@njgsmach.com