Промышленная щековая дробилка фиксированного типа с

- Категории: >>>

- Поставщик: Shenyang,Huayue,Brilliant,Machinery&equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

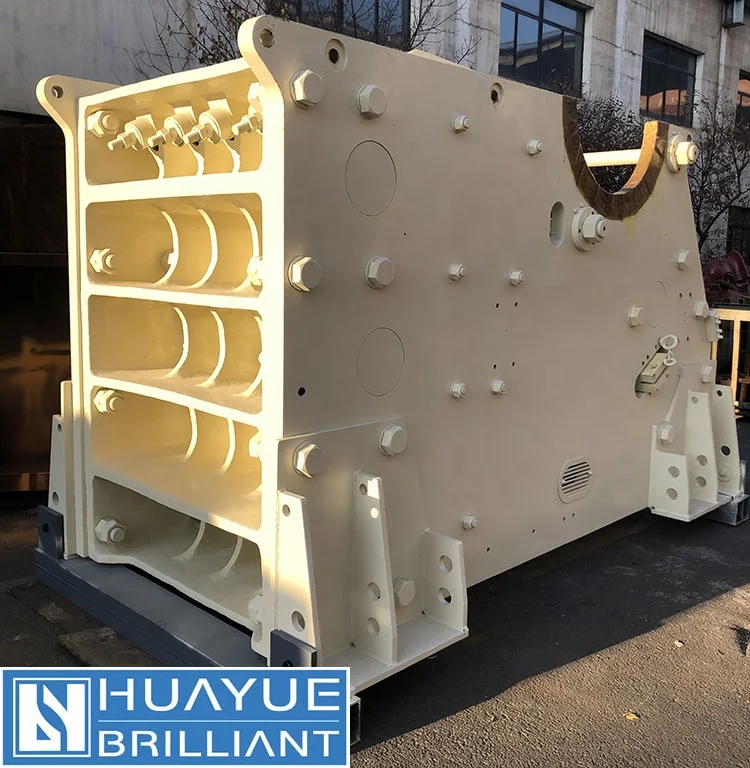

PE Series Jaw crusher commonly known as jaw broken, also known as tiger mouth. The crushing chamber is composed of two jaw plates, moving jaw and static jaw, which simulates the movement of two jaws of animals to complete the crushing operation of materials. Widely used in mining smelting, building materials, road, railway, water conservancy and chemical industries and other ores and large material crushing. The maximum compressive strength of the crushed material is 320Mpa. The upper end of the moving jaw is directly suspended on the eccentric shaft, as the connecting rod of the crank connecting rod

mechanism, driven directly by the eccentricity of the eccentric shaft, and the lower end of the moving jaw is hinged with the thrust plate to support the rear wall of the frame. When the eccentric axis rotates, the trajectory of each point on the moving jaw is from the circular line of the suspension point (the radius is equal to the eccentric distance), gradually downward into an ellipse, the lower the ellipse, the more biased, until the trajectory of the point connecting the lower part and the thrust plate is an arc line. Because this kind of mechanical moving jaw point movement trajectory is more complex, it is called jaw crusher.

mechanism, driven directly by the eccentricity of the eccentric shaft, and the lower end of the moving jaw is hinged with the thrust plate to support the rear wall of the frame. When the eccentric axis rotates, the trajectory of each point on the moving jaw is from the circular line of the suspension point (the radius is equal to the eccentric distance), gradually downward into an ellipse, the lower the ellipse, the more biased, until the trajectory of the point connecting the lower part and the thrust plate is an arc line. Because this kind of mechanical moving jaw point movement trajectory is more complex, it is called jaw crusher.

Specification

Product Name | Factory price river stone crusher equipment type powerful large capacity rock stone jaw crusher |

Application | Widely used in the field of mining, metallurgy, road & railway construction, water conservancy, chemical industry and so on. |

Working Principle:

Powered by electrical motor, movable jaw is set in reciprocate movement at predetermined track through the transmission system of driving wheel, Vee-belt, and eccentric roll-driving shaft. The material is crushed in the cavity composed by fixed jaw plate, movable plate, and side protecting plate, and discharged the end product from the bottom discharge opening.

This series jaw crusher adopts curve-movement compression way to crush the material. Electric motor drives belt and belt wheel to set the movable plate in moving up and down through eccentric shaft. When the movable jaw rises, the angle formed by toggle and movable plate will be wider, and the jaw plate will be pushed approaching the fixed plate. In this way, the materials are crushed through compressing, grinding, and abrading. When the movable plate descends, the angle formed by toggle and movable plate will became narrower. Pulled by rod and spring, the movable plate will move apart from toggle, so the crushed materials can be discharged from the bottom of the crushing cavity. Consecutive movement of motor drives the movable plate in circular crushing and discharge to realize large-quantity production.

Packing & Delivery

To ensure the safety of goods arrived in the designated port in a timely manner,and provide the port of destination14days-21days freezer use.

Company Profile

Shenyang Huayue Brilliant Machinery&Equipment Co.,Ltd is a manufacturer of a wide variety of Mining equipment, which we provide to customers all over the world. Our primary products include: Jaw Crusher, Cone Crusher, Ball Mill, Feeding Equipment, Vibrating Screen, and their related spare parts. As a direct manufacturer and dealer of mining equipment with 10 years of experience in this field, in addition to our professional technology support, HYB is able to offer the most reliable, high-quality mining equipment to our customers. Our premium products are widely used in various fields, such as: the mining, metallurgy, highway, railway, and chemical industries. Our Crushers are widely used for stone crushing in the fields of mining, metallurgy, and building material;Ball Mill are widely used for Gold Mining, Copper Mining and so on. and our Vibrating Screens are sought after for dry and wet screening in the coal, mining, quarry, and other industries. We have a strict quality control system in place throughout the entire production process, so our products are all of the highest quality and reliability. As a result, our mining equipment and other products are popular in markets all over the world. Our goal is to provide minining equipment of excellent quality and reliability, in order to establish a reputation and relationship with our customers which will keep them customers for life. We also offer OEM service upon request. If you have a need for any mining equipment, or related spare parts, please feel free to contact us. We are dedicated to serving each of our customers to their complete satisfaction.

Bauma CHINA 2020 Shanghai International Construction Machinery,Building Materials Machinery,Mining Machinery,Construction Vehicles and Equipment Expo & Myanmar International Mining&Construction Expo

Our Advantages

Feature of PE Series Jaw Crusher:

5. Simple structure, convenient maintenance: Under the basic principle of compound pendulum, the redundant parts are simplified, the overall structure of the equipment is simple, the crushing capacity is strong, the operation and maintenance is convenient, and the operating cost is low.

6. Large discharging adjustment range, multi-purpose of one machine: Gasket type discharging adjustment device, discharging adjustment range is large, increase the flexibility of the equipment when

using, can meet various processing requirements of customers.

7. Low noise and less dust: Equipment according to national standards, low noise, supporting equipment dust, control dust emission.

1.Deep cavity crushing, high yield and energy saving: Optimized deep cavity crushing, no dead zone, feeding and crushing efficiency greatly improved, single machine energy saving about 15%-30%, system energy saving more than double.

2.Strong bearing capacity and high stability: Larger forging billet processing heavy eccentric shaft, high manganese steel jaw plate and high casting steel moving jaw assembly, the equipment has stronger bearing capacity and higher stability.

3.Mature process, long service life: Drawing on the manufacturing process, the digital analysis of the operation of each component, the internal structure is carefully constructed, the service life of equipment is greatly extended.

4.Centralized lubrication system, easy maintenance: Unique design of centralized lubrication system, parts lubrication more quickly, small maintenance workload.

5. Simple structure, convenient maintenance: Under the basic principle of compound pendulum, the redundant parts are simplified, the overall structure of the equipment is simple, the crushing capacity is strong, the operation and maintenance is convenient, and the operating cost is low.

6. Large discharging adjustment range, multi-purpose of one machine: Gasket type discharging adjustment device, discharging adjustment range is large, increase the flexibility of the equipment when

using, can meet various processing requirements of customers.

7. Low noise and less dust: Equipment according to national standards, low noise, supporting equipment dust, control dust emission.

FAQ

Q1: How to choose the suitable model ?

A: Please confirm the following information :

1. what kind of stone do you want to crush ?Such as granite ? limestone ?

2. what's the size of your stone before crush ? how many inch or mm ?

3. what's your requirements of final product size ? how many inch or mm ?

4. what's your requirements of production capacity ? how many ton per hour ?

Q2. How long is the warranty? Does your company supply related spare parts?

A: The crusher equipment is warranted for one year. And we provide spare parts at reasonable price.

Q3: How long is the delivery time?

A: Generally it takes one week if the goods are in stock. Otherwise it needs 15-20 days, and it also depends on the ordered quantity.

Q2. How long is the warranty? Does your company supply related spare parts?

A: The crusher equipment is warranted for one year. And we provide spare parts at reasonable price.

Q3: How long is the delivery time?

A: Generally it takes one week if the goods are in stock. Otherwise it needs 15-20 days, and it also depends on the ordered quantity.

Maybe You Are Interested In

Cone Crusher

Jaw Crusher

Ball Mill

Impact Crusher

Hammer Crusher

HP Series Cone Crusher

Contact Us