Высокопрозрачные гранулы из полиэтилена

- Категории: LDPE >>>

- Поставщик: Shanghai,Qishen,Plastic,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

LDPE LD165BW1 | |||||

Physical Properties | Test Standard | Typical Values | Units | ||

Density | ASTM D1505 | 0.922 | g/cm³ | ||

Melt Index 190℃2.16kg | ASTM D1238 | 0.33 | g/10min | ||

Mechanical behavior | Test Standard | Typical Values | Units | ||

Tensile Strength Flow Yield | ASTM D882 | 13 | MPa | ||

Tensile Strength xFlow Yield | ASTM D882 | 12 | MPa | ||

Tensile Strength Flow Break | ASTM D882 | 20 | MPa | ||

Tensile Strength xFlow Break | ASTM D882 | 18 | MPa | ||

Elongation Flow Break | ASTM D882 | 280 | % | ||

Elongation xFlow Break | ASTM D882 | 540 | % | ||

Falling Weight lmpact Strength | ASTM D1709 | 490 | g | ||

Elmendorf Tear Strength Flow | ASTM D1922 | 260 | g | ||

Elmendorf Tear Strength xFlow | ASTM D1922 | 460 | g | ||

Secant Modulus 1% Flow | ASTM D882 | 230 | MPa | ||

Secant Modulus 1% xFlow | ASTM D882 | 280 | MPa | ||

Optical performance | Test Standard | Typical Values | Units | ||

Gloss 45° | ASTM D2457 | 45 | |||

Haze | ASTM D1003 | 15 | % | ||

Thremal Properties | Test Standard | Typical Values | Units | ||

Melting Temperature Peak | INTERNAL METHOD | 109 | ℃ | ||

LDPE (Low-Density Polyethylene) is a thermoplastic polymer known for its unique characteristics. It is flexible, lightweight, and exhibits good chemical resistance.

LDPE is easily processed and has excellent transparency. It is widely used in packaging, films, and various applications requiring flexibility and chemical resistance.

LDPE LD165BW1

Features:

Non slip agent

High strength

Product Application

Foam

Heavy-duty bags

Agricultural film

Application:

1. Construction Applications

2. Heavy-duty bags

3. Agricultural film

3. Agricultural film

4. Foam

5. Shrink wrap

5. Shrink wrap

6. Film

7. Profiles

Film

Factory video

Company Profile

Founded in July 2007, Shanghai Qishen Plastic Industry Co.,Ltd is a manufacture of high-performance modified plastics. focusing on the R&D. Our factory occupies an area of 8181 square meter with 10 twin-screw extruders which can extrude different modified polymers that are widely being used in home appliances. Automotive industries, electronics, office equipment etc with more than 60 employees.

These polymers mainly includes PP, PC, ABS, PBT, Masterbatch etc. Meanwhile we have established a reliable quality management system based on the multi-function laboratory tests. we will continue to devote in providing the most suitable product solutions for our customers in the future.

These polymers mainly includes PP, PC, ABS, PBT, Masterbatch etc. Meanwhile we have established a reliable quality management system based on the multi-function laboratory tests. we will continue to devote in providing the most suitable product solutions for our customers in the future.

Exhibition

Product packaging

Certifications

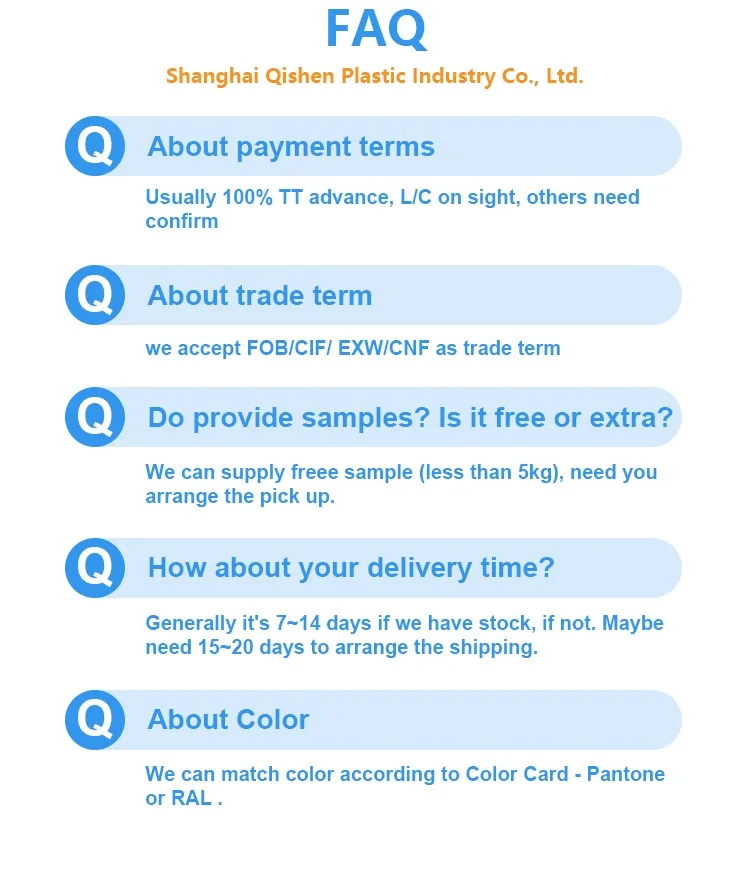

FAQ

Contact Information

Похожие товары

Гранулы ПНД, пластиковое сырье, гранулы ПНД-пленки

US $650.00-$1100

Прозрачная пленка LDPE/перерабатываемый Пластиковый лом LDPE/пленка LDPE

US $65.00-$100.00

Ldpe Смола ldpe цены на сырье для общего пластикового сырья HDPE/LDPE/LLDPE

US $513.00-$764.00