Ldpe инъекционные натуральные гранулы полиэтилена

- Категории: LDPE >>>

- Поставщик: Shandong,Dawn,International,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

plastic raw materials-pe resin granules/hdpe/ldpe/lldpe raw material

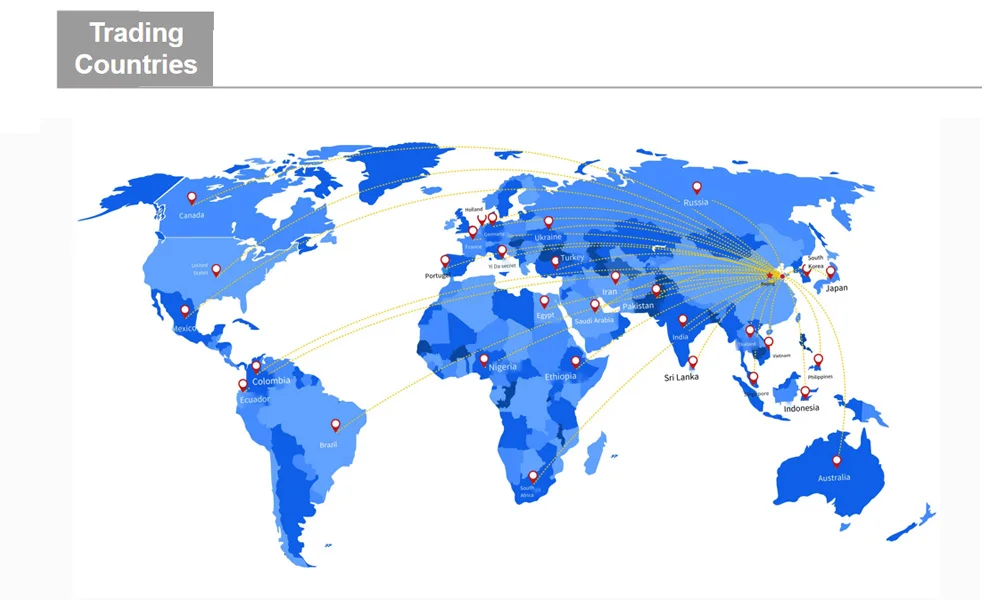

Dawn annual sales of plastic raw materials exceed 4 million tons, with a compound growth rate of over 20% in the past five years. It mainly engages in synthetic resin and rubber products such as general plastics and engineering plastics. Upstream has established deep strategic cooperation with PetroChina, Sinopec, ChinaCoal, Shenhua, Yanchang Oil, Sibul Russia and other major petrochemical companies at home and abroad. It operates more than 3600 trade brands and has won the honors of gold partner and excellent dealer of PetroChina, Sinopec, ChinaCoal and other petrochemical companies for many consecutive years.

Downstream services are provided to customers in the entire field of plastics, with over 30000 users and over 30 branches nationwide, as well as over 200 warehouses, meeting customers' real-time procurement needs.

Polyethylene (polyethylene, PE for short) polyethylene is divided into linear polyethylene and branched polyethylene according to the structure of the polymer chain.

It is usually divided according to density into high density polyethylene (HDPE), medium density polyethylene (MDPE), low density polyethylene (LDPE) and linear low density polyethylene (LLDPE).

.

The main parameters of polyethylene are density and melt index. Density characterizes the tightness between the long main chains of the polymer and the regularity (or crystallinity) of the structure; melt index characterizes the relative molecular weight of the polymer.

It is usually divided according to density into high density polyethylene (HDPE), medium density polyethylene (MDPE), low density polyethylene (LDPE) and linear low density polyethylene (LLDPE).

.

The main parameters of polyethylene are density and melt index. Density characterizes the tightness between the long main chains of the polymer and the regularity (or crystallinity) of the structure; melt index characterizes the relative molecular weight of the polymer.

Specification

High density polyethylene (HDPE), commonly known as low pressure polyethylene, is a copolymer of ethylene and a small amount of alpha-olefin, with a density of 0.941-0.96 and a melting point of 131-137°C. It has high temperature resistance, oil resistance, steam permeability and resistance to environmental stress cracking, excellent electrical insulation, impact resistance and cold resistance, and is mainly used for blow molding, injection molding, extrusion of pipes, films, profiles and rotomolding of large hollow products, etc.

Low density polyethylene (LDPE) is commonly known as high pressure polyethylene, the irregularity of the branched chain structure makes LDPE less crystalline, with a lower density of 0.910-0.925 and a lower melting point of 105-115°C. It has good flexibility, extensibility and transparency and is mainly used for the production of plastic bags, agricultural films, etc.

Linear low density polyethylene (LLDPE), is a copolymer of ethylene and alpha-olefin such as 1-butene (C4), 1-hexene (C6) and 1-octene (C8), copolymer monomer content of 8%-10%, its molecular chain does not exist long branched chain, has a narrower molecular weight distribution, density of 0.910-0.925, melting point 122-124 ℃. LLDPE crystallinity is high. The largest application area for LLDPE is film, producing films with higher puncture resistance and tear resistance than LDPE. It has penetrated most LDPE application areas such as food bags, agricultural films, geomembranes, injection molded closures, various containers, paint cans, rotomoulded drums and other hollow products.

Low density polyethylene (LDPE) is commonly known as high pressure polyethylene, the irregularity of the branched chain structure makes LDPE less crystalline, with a lower density of 0.910-0.925 and a lower melting point of 105-115°C. It has good flexibility, extensibility and transparency and is mainly used for the production of plastic bags, agricultural films, etc.

Linear low density polyethylene (LLDPE), is a copolymer of ethylene and alpha-olefin such as 1-butene (C4), 1-hexene (C6) and 1-octene (C8), copolymer monomer content of 8%-10%, its molecular chain does not exist long branched chain, has a narrower molecular weight distribution, density of 0.910-0.925, melting point 122-124 ℃. LLDPE crystallinity is high. The largest application area for LLDPE is film, producing films with higher puncture resistance and tear resistance than LDPE. It has penetrated most LDPE application areas such as food bags, agricultural films, geomembranes, injection molded closures, various containers, paint cans, rotomoulded drums and other hollow products.

Product Applications

Packing & Delivery

25 kgs/bag

Company Profile

Exhibition

Похожие товары

Гранулы ПНД, пластиковое сырье, гранулы ПНД-пленки

US $650.00-$1100

Прозрачная пленка LDPE/перерабатываемый Пластиковый лом LDPE/пленка LDPE

US $65.00-$100.00

Ldpe Смола ldpe цены на сырье для общего пластикового сырья HDPE/LDPE/LLDPE

US $513.00-$764.00