Описание и отзывы

Характеристики

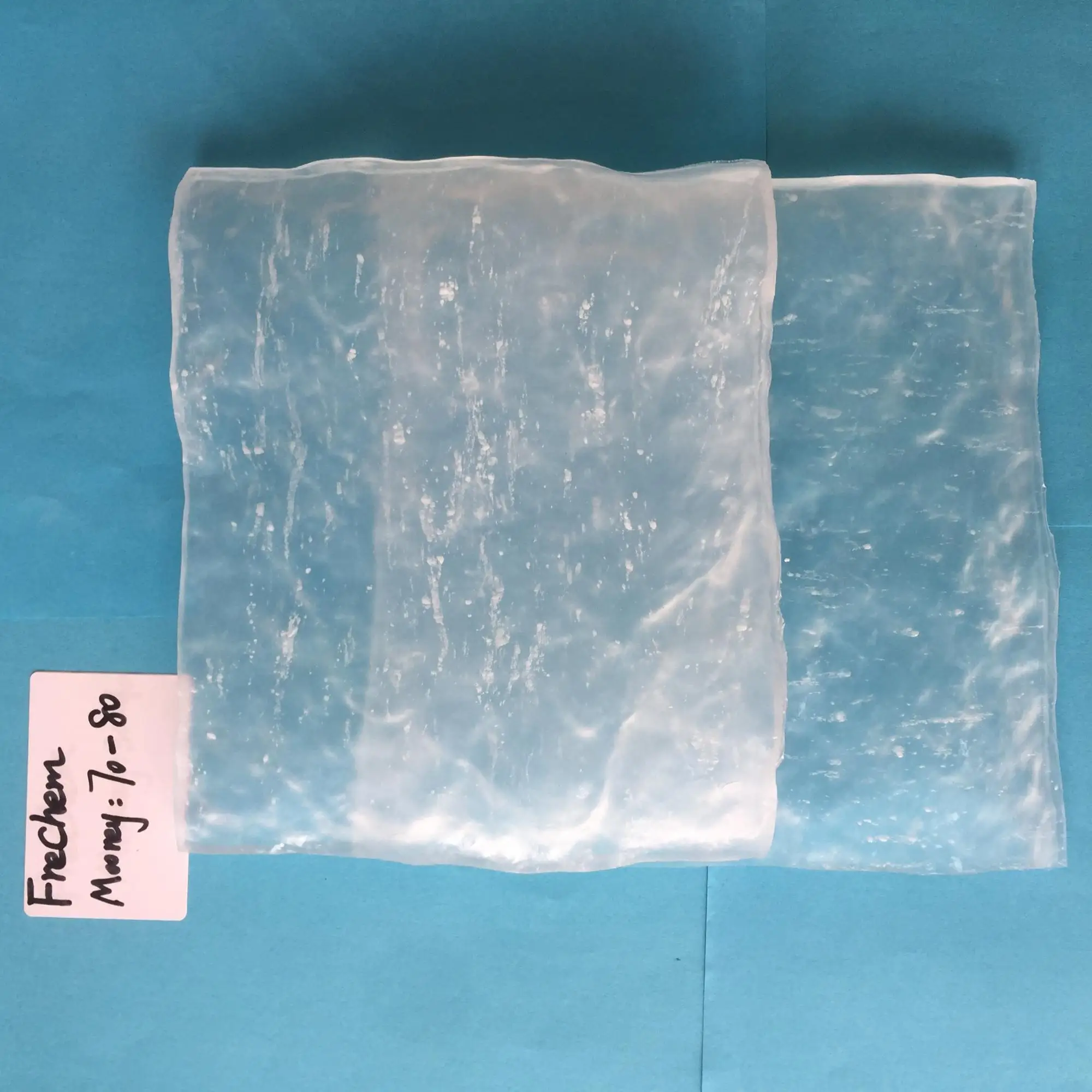

FreChem FKM fluoroelastomer gum raw FKM rubber

TDS of FreChem FKM raw gum

Fluoroelastomer was introduced in 1957 to meet the needs of the aerospace industry for a high performance seal elastomer.

Since then, the use of fluoroelastomer has expanded to many other industries, especially in the automotive, fluid power, appliance, and chemical fields.

With over half a century of proven performance, fluoroelastomer has developed a reputation for outstanding performance in high temperature and extremely corrosive environments.

| FreChem FKM raw gum Copolymer | ||||||

| Technical indexes | ||||||

| Items | C20 | C30 | C40 | C50 | C70 | C120 |

| Appearance | White or light-yellow sheet, no visible impurities | |||||

| Density (g/cm3) 23 °C | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 |

| Mooney viscosity(ML(1+10)121°C) | 25+5 | 35+5 | 45+5 | 45+5 | 75+5 | 120-140 |

| Tensile strength after press cure(MPa) 1770C,10min≥ | 8 | 8 | 9 | 9 | 9 | 9 |

| Tensile strength after post cure(Mpa) 2300C,24H≥ | 10 | 10 | 11 | 13 | 11 | 12 |

| Elongation at break after press cure ( Mpa) 1770C,10min≥ | 180 | 180 | 180 | 180 | 180 | 180 |

| Elongation at break after post cure ( Mpa) 2300C,24H≥ | 160 | 160 | 160 | 160 | 160 | 160 |

| 200°C 70H Compressibility20% Compression set (%)≤ | 20 | 20 | 20 | 20 | 20 | 12 |

| 200℃,in No.3 jet fuel, weight increase after 24H (%)≤ | 5 | 5 | 5 | 5 | 5 | 5 |

| Water content (%)≤ | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.1 |

| Rubber compounds recipe: | FKM: 100g | AF: 2.0g | BBP:0.5g | MgO:3.0g | Ca(OH)2:6.0g | N990:30g |

Press Cure 177℃@10min;;Post Cure 230℃@24hour

Rubber compounds recipe:FKM:100;AF:2.0;BPP:0.5;MgO:3.0;Ca(OH)2:6.0;N990:30.0

| FKM | Fluoroelastomer | FKM material | Fluorous rubber | Fluorine carbon rubber |

| Viton | Fluororubber | FPM | viton raw gum | FKM elastomer |

Other name

TDS of FreChem Fluoroelastomer raw gum Terpolymer

| FreChem FKM raw gum Terpolymer | ||||||

| Technical indexes | ||||||

| Items | T20 | T30 | T40 | T70 | T100 | |

| Appearance | White or light-yellow sheet, no visible impurities | |||||

| Density (g/cm3)23 °C | 1.84-1.88 | 1.84-1.88 | 1.84-1.88 | 1.84-1.88 | 1.84-1.88 | |

| Mooney viscosity(ML(1+10)121°C) | 20-30 | 30-40 | 40-50 | 60-90 | 90-120 | |

| Tensile strength after press cure(MPa) 1770C,10min≥ | 9 | 9 | 9 | 9 | 10 | |

| Tensile strength after post cure(Mpa)2300C,24H≥ | 10 | 11 | 11 | 11 | 12 | |

| Elongation at break after press cure ( Mpa) 1770C,10min≥ | 180 | 180 | 180 | 180 | 180 | |

| Elongation at break after post cure ( Mpa) 2300C,24H≥ | 160 | 160 | 160 | 160 | 160 | |

| 200°C 70H Compressibility20% Compression set (%)≤ | 30 | 30 | 30 | 30 | 30 | |

| Oil resistivity | 180℃×24h 4109 bisphenol oil resistivity (%)≤ | 6 | 6 | 6 | 6 | 6 |

| (200℃×24h) RP-3 oil resistivity (%) ≤ | 7 | 7 | 7 | 7 | 7 | |

| Water content (%)≤ | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| Rubber compounds recipe: | FKM: 100g | AF: 2.0g | BBP:0.5g | MgO:3.0g | Ca(OH)2:6.0g | N990:30g |

| Technical date sheet,Press Cure 177℃@10min;Post Cure 230℃@24hour | ||||||

| FKM | fluoroelastomer | FKM material |

| Viton | fluororubber | viton raw gum |

Other name

Jiangsu FreChem Co., Ltd

FreChem is a professional research & development,manufacturer of high performance rubber compounds, special additives and fluorochemicals.

Starting from 2007, FreChem has now become one of the leading manufacturers of FKM rubber compounds and fluoropolymers in China.

Thanks to our research & development capabilities, FreChem is able to provide highly qualified fluoroleastomer and fluoropolymers to global customers : Fluoroelastomer(FKM), FFKM (perfluoroelastomer), Fluorosilicones(FVMQ),PFA resin ( perfluoroalkoxy copolymer resin ), PVDF resin ( Polyvinylidene Fluoride ), PTFE resin, ETFE resin, PVDC resin and so on.

FreChem expects to offer best solution as well as customization in order to meet customers’ special needs. The equipment and special know- how used in production control guarantee that our compounds respond to the customer requirement and provide high consistency standards.

Our vision is to become an excellent partners with customers and we will improve and focalize our skill on final application to develop compounds with high added value.

A: We are factory.

A: Yes, we could offer the sample for free charge and you only pay the freight of express.

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment.

Contact us

send your message to supplier