Высокотемпературный 1260 модуль керамического волокна огнеупорный высокоглиноземный 1360

- Категории: Ceramic Fiber Module >>>

- Поставщик: Zhengzhou,Rongsheng,Refractory,Co.,Limited

Поделиться:

Описание и отзывы

Характеристики

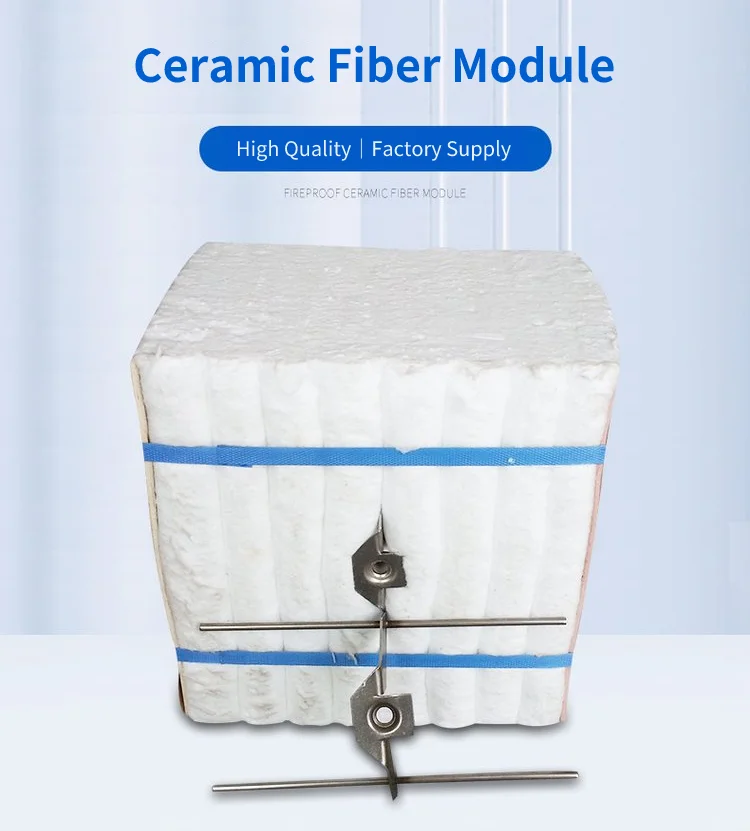

Ceramic Fiber Module Descriptions

Ceramic fiber module are made from compressed ceramic fiber blanket.Ceramic fiber module is produced by various anchoring systems, white color, regular size, good refractory heat insulation effect, classified temperature 1050-1400 °C, used in various kiln lining insulation and various thermal equipment lining.

Characteristics

Low bulk density,low thermal conductivity.

Resistance to heat-shock, ability to resist the scouring of airflow.

Excellent mechanical strength ,Good safety with anchor inside

Easy to install. after installing the lining form a seamless space, good insulation effect.

Technical Index

Ceramic fiber modules can be divided into the following types based on temperature grade

1050℃ Ordinary ceramic fiber module

1260℃ Standard ceramic fiber module

1260℃ High purity ceramic fiber module

1350℃ High aluminum ceramic fiber module

1430℃ Zirconium type ceramic fiber module

1600℃ ceramic fiber module

| Ceramic Fiber Module | RS1050 | RS1260ST | RS1260HP | RS1350 HA | RS1430 Zr | RS1600 PMF | |

| Classification Temperature | 1050 | 1260 | 1260 | 1350 | 1430 | 1600 | |

| 192kg/m3/at()℃/24h Linear Shrinkage Rate | ≤2.0 (850℃) | ≤2.0 (1000℃) | ≤2.0 (1050℃) | ≤2.0 (1100℃) | ≤2.5 (1200℃) | ≤1.5 (1450℃) | |

| Density (KG/M3) | 172-240 | 172-240 | 172-240 | 172-240 | 172-240 | 172-240 | |

| Thermal Conductivity Rate(W/m.k) | 400℃ | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | - |

| 600℃ | 0.15 | 0.15 | 0.15 | 0.12 | 0.12 | 0.12 | |

| 800℃ | 0.22 | 0.20 | 0.19 | 0.18 | 0.16 | 0.15 | |

| 1000℃ | - | - | 0.22 | 0.12 | 0.19 | 0.18 | |

| Chemical Composition(%) | Al2O3 | 42-44 | 45-46 | 47-49 | 52-55 | 34-36 | 72-75 |

| Al2O3+SiO2 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | |

| ZrO3 | - | - | - | - | 15-17 | - | |

| Other | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | |

Standard Size and Package

(300-600)*300*(150-300)mm,(Other specifications according to customer's inquires).

Density:172KG/M3,192KG/M3,220KG/M3,240KG/M3

Package:Carton+Pallet.

Installation:RONGSHENG also provide professional construction guidance and installation services.

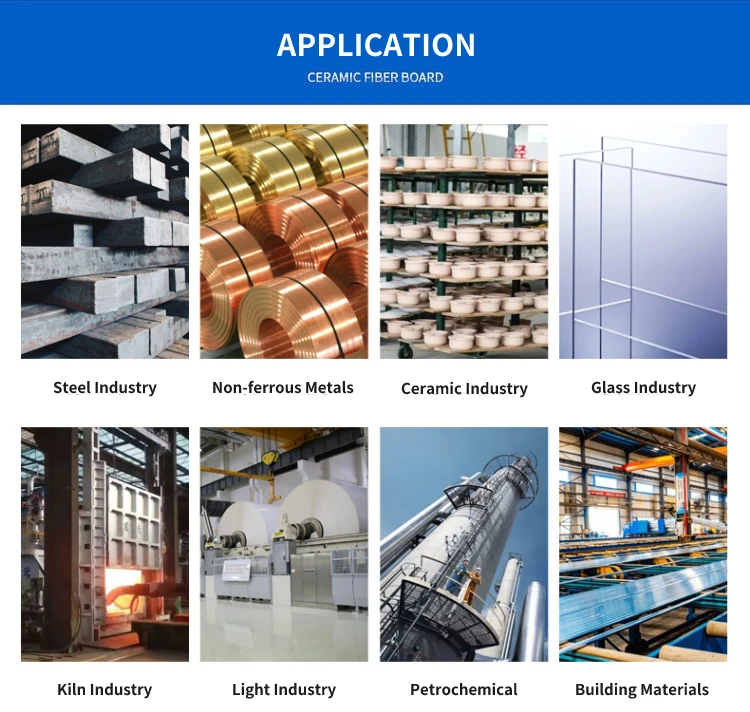

Application of Ceramic Fiber Module

1.Steel Industry: Heat treatment furnaces Ladle cover, annealing furnace,rotary furnace,bell furnace,walking beam furnace,hot air and flue pipes etc.

2.Ceramic Industry:Tunnel kiln, shuttle kiln, end-fired furnaces, roller kiln.

3.Petrochemical Industry: Atmospheric furnace, transforming furnace, coking furnace, cracking furnace, flue etc.

4.Heat-treatment industry: Annealing furnaces, normalizing furnaces, drawing furnaces, pit furnaces, kiln cars.

5.High- temperature equipment: For example, pot furnaces, electricity resistance furnaces and other kinds of industrial furnaces.

6.Green energy industry:Waste incinerators, RTO exhaust treatment furnace, SCR environmental catalytic stove etc.

Zhengzhou Rongsheng Refractory Material Co., Ltd.

Established in the early 90s of twenty century, with continuous innovation and development, now we are a comprehensive enterprise in refractory material industry, covering metallurgy, building materials, electric power, chemical industry,etc.

Our main products: refractory material for industrial furnaces, such as high-alumina brick, clay brick, silicon brick, high-strength diatomite brick, light weight insulation brick, low iron mullite brick, etc.; anti-stripping alumina brick, alkali proof brick, phosphate brick for cement industry; For the industrial furnace and power boiler, we can provide abrasive brick, corundum brick, mullite brick, wear resistant castable, corundum castable, high strength low cement castable, impervious material, plastic refractory, graphite electrode etc.

Our main export markets : North America, Western Europe, Eastern Europe, South America, Southeast Asia, Eastern Asia, Mid East, Oceania, Africa

We have own workshop , advanced production line , experienced workman and stricted check out flow .

We always pursue the objective of "Honesty, Courtesy, Innovation, Dedication", the cornerstone of "Super Quality & Competitive Price", and the strategic goal of building Rongsheng brand, to serve the clients in a timely and effective way.