Китайские станки для плазменной резки с ЧПУ двумя режущими

- Категории: >>>

- Поставщик: Jinan,Bob,CNC,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product features

1. Frame adopts carbon steel welding structure and overall annealing treatment with high precision

and small inertia .XYZ axis is with high precision processing to prevent deformation.

2. Transmission structure is high precision rack and special reducer, Cable made by the German

materials to ensure running accuracy.

3. The drive system adopts USA chip control, double drive, Panasonic Servo motors. Inovance Servo

motor or precision stepper motor are also available to providing AC power with big torque to ensure

running smoothly under the high speed.

4. Adopts high precision controller, with English and Chinese language. And the machine also equip withAutomatic THC.

5. Optional machine size: A,40120: 4m*12m(6m, 8m, 10m) B,30120: 3m*12m(6m, 8m, 10m)

Technical paramters

Model | FM-300LMX3080HD | |

Cutting method | Plasma | Flame |

Cutting size | 2000*6000mm | |

Machine size | 3000*8000mm | |

Lifting travel | ≤170mm | |

Max travel speed and cutting speed | 10000mm/min 0-15000 mm/min | |

Running accuracy | ≤0.005mm | ≤0.1mm |

Height control | Arc pressure THC | Lifting body |

Cutting thickness | According to the power supply, (less than 20mm is the best) | 6-200mm |

cutting gas | air | Oxygen + ethyne(Propane) |

Gas pressure | 0.4-0.8Mpa for normal plasma power | |

Drive system | Dual drive | |

Stepper motor | Stepper motor and driver | |

X, Y axis | High Quality Rack & Pinion and 18kg linear rail | |

Auto ignition | AR235(Optional) | |

Power | 380V 50HZ | |

No. of cutting torch and nozzle | 1 set of plasma/flame cutting torch, 10 pcs nozzles | |

Software | FASTCAM | |

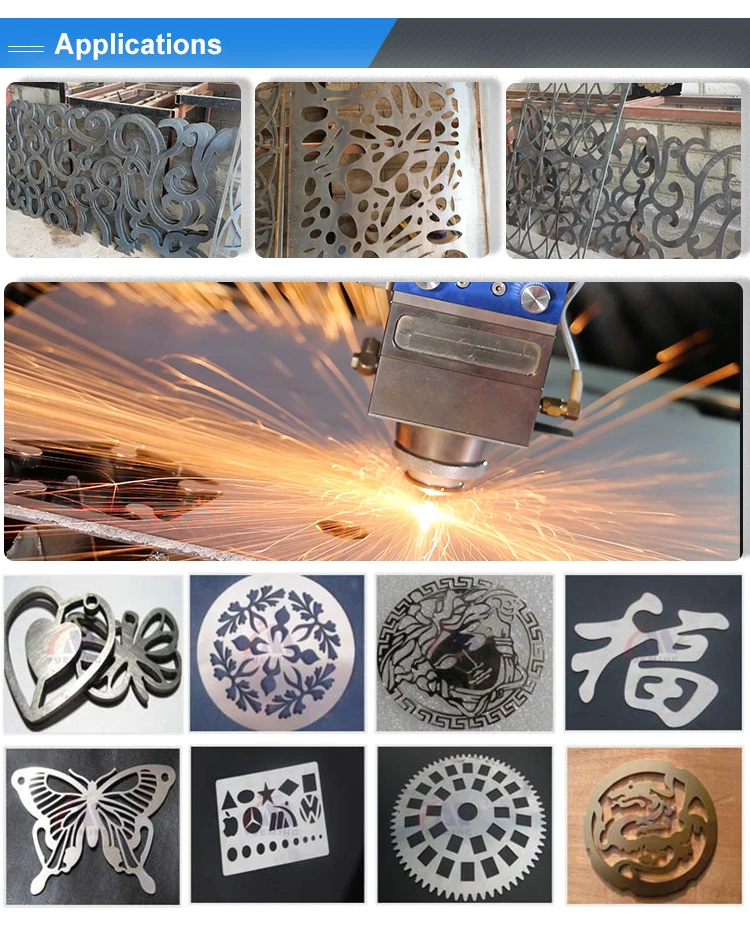

One-stop solutions for cnc cutting machine