STA высококачественный кремниевый Карбид SiSiC/SIC балки/ролик из карбида

- Категории: Refractory >>>

- Поставщик: Sta,Refractory,(zhengzhou),Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

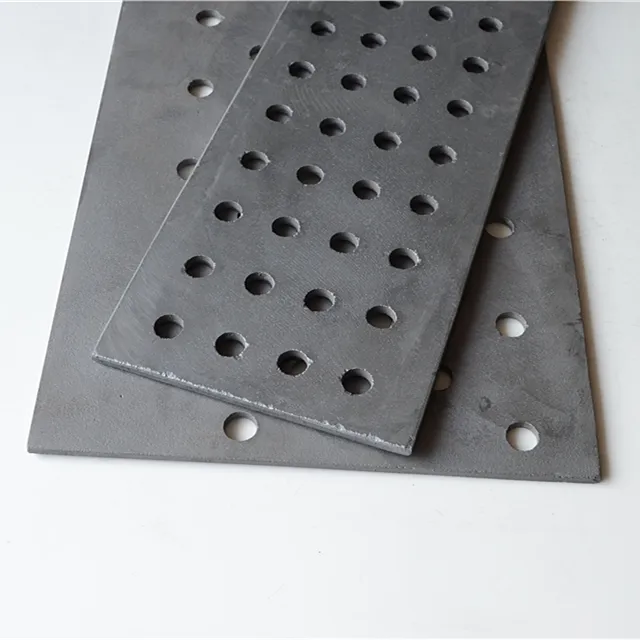

STA SiSiC Reaction boned Silicon Carbide Beams Used in Kiln Furnaces for industry of consumer porcelain, sanitary ceramics, building ceramics and magnetic materials. STA also provide silicon carbide batt, plate, tube, roller, etc.

Benefits:

Superior Oxidation Resistance

Improved Performance

Lowered Cost Burden

Longer Life Between Replacement / Rebuilds

Allows Lower Weight

Very High Thermal Conductivity

STA Silicon carbide beams are widely used in industrial production

Automobile Industry

Boiler Industry

Chemical Industry

Crystallite Glass Industry

Magnetic Materials Industry

Metallurgy

Metallurgy Industry

Paper Industry

Petroleum Industry

Life is several times than others.

Material: All kinds of kilns

Technical Parameters of silicon carbide beams

item | unit | data |

temperature of application | C | 1380 |

density | g/cm3 | >=3.02 |

open porosity | % | <0.1 |

bending strength | Mpa | 250(20C) |

Mpa | 280(1200C) | |

modulus of elasticity | Gpa | 330(20C) |

Gpa | 300(1200C) | |

thermal conductivity | W/m.k | 45(1200C) |

coefficient of thermal expansion | K-1*10-6 | 4.5 |

rigidity |

| 13 |

acid-proof alkaline |

| Excellent |

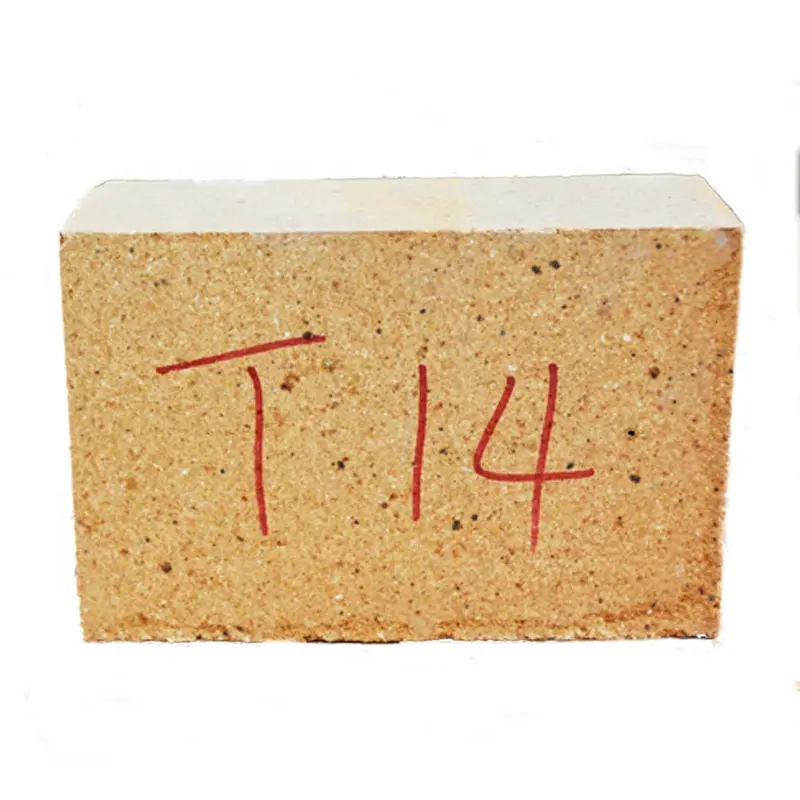

STA is able of customizing kiln shelves,beam,batts, sagger,etc,according to customer requirements, such as furnace temperature, use of time, frequency of use, etc.,These products can be made into Mullite, clay bonded compound, oxide bonded compound, recrystallized silicon carbide,Si3N4 bonded compound,or refractory sintering,to satisfy technical requirements of clients.

STA takes a system approach to manage so that a consistent product is delivered according to customer’s requirement:

STA will review the requirements related to the product. Then ensures the requirements are defined and we have the ability to meet the defined requirements.

During production, we control carefully and keep communication with the clients.

After production we discuss the feedback from productive department and the clients.

Then, we file the customer information including the order requirement so that we improve in the future.

After the ordered has been confirmed, Service Process Diagram is as follows:

To confirm the requirement

To allocate production tasks

To supervise productive process

To deliver the goods and settle accounts

To discuss the feedback from productive department and clients

To file the customer information including order requirement, production process

To make Improvement plan

In order to ensure better quality, we carry out five processes test below:

1. Material inspection and sample test

2. Semi-manufactured goods inspection

3. Process control and inspection

4. Finished products inspection

5. Shipment inspection

Our goal is provide the highest quality products with best service and good delivery time that meet customer requirements; provide continuous improvements in methods and processes and products; work according to an environmentally friendly way of recycling products in all phases of manufacture and use.

High puriy material make sure high max working temperature,

Tight tolerance make sure the right installation.

Large quantity Crucibles in stock ensured fast delivery

Large capacity reduce crucible prices

Why choose mission

High puriy material make sure high max working temperature,

Tight tolerance make sure the right installation.

Large quantity products in stock ensured fast delivery

Large capacity reduce the prices

1.What's your advantage to other suppliers?

We have our own factory which has more than 15years experience in producing and exporting silicon carbide ceramic products,

we also have good business relations with some other factories.

Our goods’quality is high and price is reasonable and delivery is fast.

2.Can you produce as our drawing?

Yes,we have skilled technical engineer who can make products according to your photos or drawings.

3.After-Sale service:

1) 24 hours service for customers.

2) quality issue, we accept reworking if quality is not reach your requirements.

3) sample available for free

4) CE service acceptable. welcome your artwork.