Dispersion Kneader / Rubber

- Категории: Internal Mixers >>>

- Поставщик: Qingdao,Eenor,Science&Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

STRUCTURAL FEATURES:

The internal mixers of this series adopt elliptical tangential rotors. The wings and working surfaces of the rotors, the internal surfaces of the mixing chamber, and the working surfaces of the pressing ram device and the discharge device are all coated on with wearable hard alloy by built-up welding method, which are durable and corrosion proof and have a long service life.

The rotors, the mixing chamber and the discharging door are all structured with circulating channels to realize the circulation of heat transmission mediums. According to different processing requirements, the mixing materials may be heated by hot steam or cooled by cold water.

The mixing chamber is a combined configuration, which is convenient for assembling, disassembling and maintaining. The drop-door discharge device is driven by two reciprocating oil cylinders which directly pull the locking plate to lock the discharge door. The device provides fast discharging and reliable airproof.

The rotors are supported by rolling bearings, which are easy to maintain and have a long service life.

The transmission system adopts a hard facing gear reducer, which has a compacted structure with higher transmission efficiency, lower noise and longer service life.

The pressing ram device may be driven by pneumatic cylinder or oil cylinder to press onto the mixing materials to force them equally mixed so as to increase productive efficiency. Mated with the electric controller, the pressing ram device can automatically add pressure, release pressure or just keep floating.

Both manual and automatic modes are arranged to operate PLC electric control system. It is easy to exchange the modes and reliable to operate the controller.

Main Technical Parameter:

Item | X(S)N-10X32 | X(S)N-20X34 | X(S)N-35X30 | X(S)N-55X30 | X(S)N-75X30 | X(S)N-110X30 | ||

Total volume of mixing chamber | L | 25 | 45 | 75 | 125 | 180 | 250 | |

Working volume of mixing chamber | L | 10 | 20 | 35 | 55 | 75 | 110 | |

Driving motor power | KW | 15 | 22 | 55 45 | 75 55 | 110 95 | 185 | |

Tilting motor power | KW | 1.1 | 1.5 | 2.2 | 2.2 | 4 | 4 | |

Tilting angle | ° | 140 | 140 | 140 | 140 | 140 | 140 | |

Rotational speed of the rotor(front/rear) | r/min | 32/23.5 | 34/28 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | |

Pressure of compressed air | MPa | 0.5∼0.8 | 0.5~0.8 | 0.5∼0.8 | 0.6∼0.8 | 0.6∼0.8 | 0.6∼0.8 | |

Capacity of compressed air | M3/min | ≥0.5 | ≥0.7 | ≥0.9 | ≥1.0 | ≥1.0 | ≥1.5 | |

Pressure of cooling water(rubber mixing) | MPa | 0.2∼0.4 | 0.2∼0.4 | 0.3∼0.4 | 0.3∼0.4 | 0.3∼0.4 | 0.3∼0.4 | |

Pressure of heating steam(plastics mixing) | MPa | 0.5∼0.8 | 0.5∼0.8 | 0.5∼0.8 | 0.5∼0.8 | 0.5∼0.8 | 0.5∼0.8 | |

| L | mm | 2580 | 2630 | 3200 | 3280 | 3330 | 3930 |

Overall dimensions | W | mm | 1300 | 1520 | 1900 | 1930 | 2620 | 3000 |

| H | mm | 2280 | 2550 | 2950 | 3070 | 3340 | 3660 |

Weight | Kg | 3300 | 4500 | 6500 | 7500 | 10500 | 14500 | |

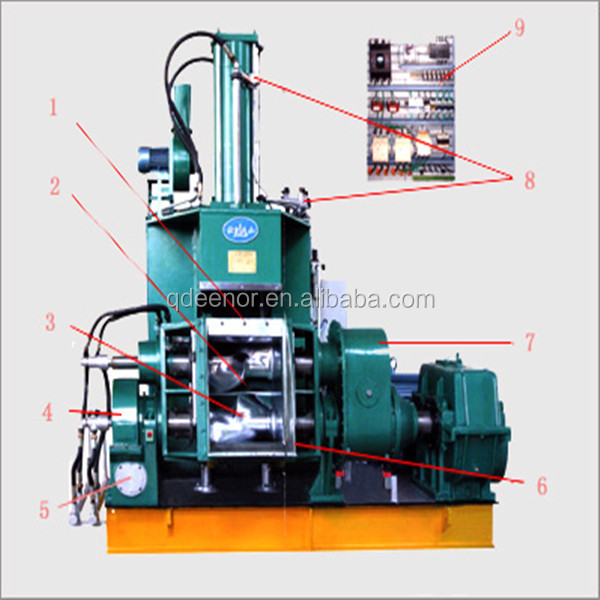

Regarding the details of kneader machine,kindly check the picture as above

1.Mixing chamber

From high quality steel plate welded into a W-shaped body and two side panels. Jacketed structure for cooling or heating. The inner surface of hard chrome plating.

2,Thermal resistance

Inserted in the middle of the bottom of the mixing chamber is equipped with thermal resistance, and electric control system phase, monitoring, control the mixing temperature.

3,Rotor

The primary class wrapped rotor. The rotor shaft center hole and ledge interior chamber, a cooling, heating channel. Edge peak and the end surfacing wear carbide, polished, hard chrome plated polished.

4,Heating cooling system

Adopt a common piping system to allow cooling water or heating steam into the rotor through the ribs in three columns, mixing chamber, and the ram cavity, the material for circulating cooling or heating.

5,Turnover mechanism

The brake motor, cycloid reducer peace enveloping worm gear, etc., and drive around the front rotors turning the mixing chamber 140 °.

6,Dust-proof sealing device

Mixing chamber catchy cantilever rack interface board slot using arc labyrinth structure, good dustproof effect; rotor shaft using the contact spring tension without lubrication structure, reliable sealing.

7,Main transmission system

By the main motor, reducer, and the composition ratio gear box, easy to achieve two opposite differential rotation of the rotor. transmission system

8,Porosity system

Controlled by the PLC instruction, two-way lift cylinder to drive the ram. When mixing overload, the ram automatically go up, you can protect the motor. When necessary, you can manually force the ram pressure rises.

9.Electronic control system

Imported PLC devices, electronic control components are all imported products or the introduction of technology to improve the system reliability.

Certification:

Customers visiting:

(1)Train how to operate and maintain the equipment, we can also offer a house call to install and debugging.

(2)Provide the formers of many specifications, and we can make according to your demand.

(3)Guarantee to keep the machine in good repair.

1.Q:Are you a factory or trading company?

A:We are factory,passed CE,BV certification.

2.Q:Where is your factory?How can i visit ?

A:Our factory located in qingdao city.You can fly to qingdao liuting airport,then we can pick you up to our facotry to visit.Warm welcome visit us.

3.Q:How does your factory control the quality of machines and after sales service?

A:Our machines passed CE,BV,ISO,SGS certification,pls confirm the quality.All our machines have 1 year guarantee, will provide lifetime maintenance.