Высококачественный наконечник для бака сжиженного углеводородного

- Категории: Chemical Machine Parts >>>

- Поставщик: Henan,Shenzhou,Precision,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

At SHENZHOU, we specialize in the fabrication of conventional tank heads, from carbon, alloy, and low alloy steels, stainless clad,titanium, nickel, Aluminum and SA516 grade 70 carbon steel. Our products are primarily intended for use as pressure vessels, tanks, and boilers, and manufactured to all applicable GB, ASME, DIN, and GOST standards.

Tank heads can be fabricated in configurations such as, dished or flanged only, standard flanged and dished, ASME flanged and dished, or ASME 2:1 semi elliptical. We possess the welding capabilities to accommodate almost any design or applicable standard, our certified welders and advanced welding equipment are prepared to provide stick-electrode, semi-automatic, gas shielded, and submerged arc welding. Manufacturing seamless tank heads from 6" up to 260" in diameter, in thicknesses from 3/19" to 15", with various prepped edges, such as trimmed, untrimmed, beveled, or tapered. We also offer stress relieving and blasting services including post weld heat treating, normalizing, and annealing. A wide array of specialized testing is also available, with full test data reporting.

| DN | Straight edge | Gradient | Tolerance of total depth(height) |

| DN≤2000mm | h=25 | outer:1.5inner:1.0 | (-0.2~+0.6)%DN |

| DN≥2000mm | h=40 | outer:2.5 inner:1.5 | (-0.2~+0.6)%DN |

| Others | outer:6%h &≤5 inner:4%h &≤3 | (-0.2~+0.6)%DN |

The Professional and modernized cold pressing production line

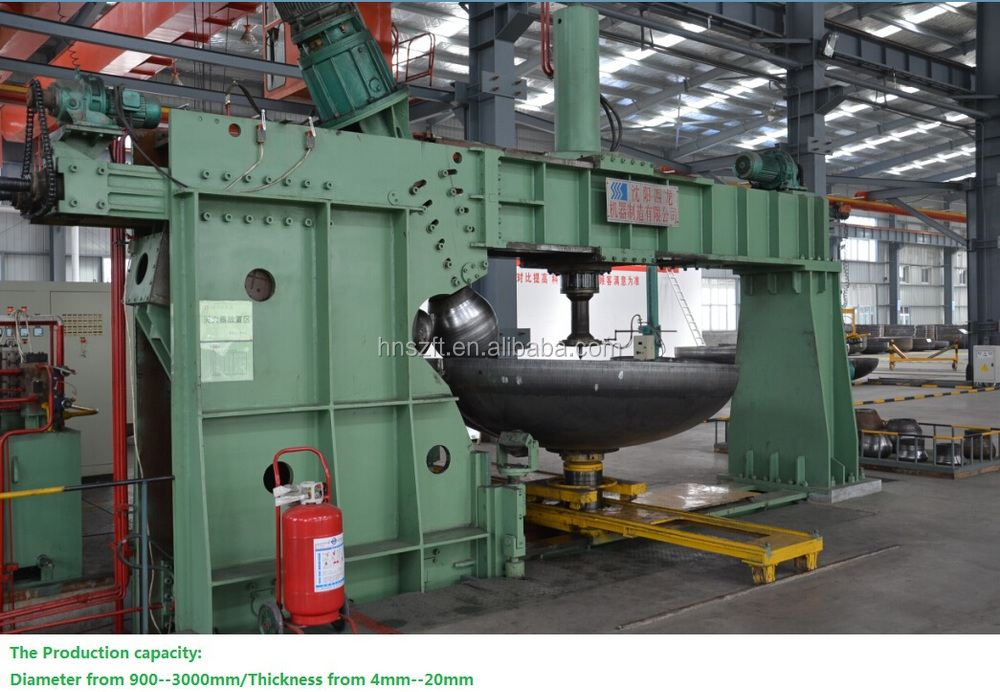

The cold pressing machine

The Edging machine

The Cap press machine

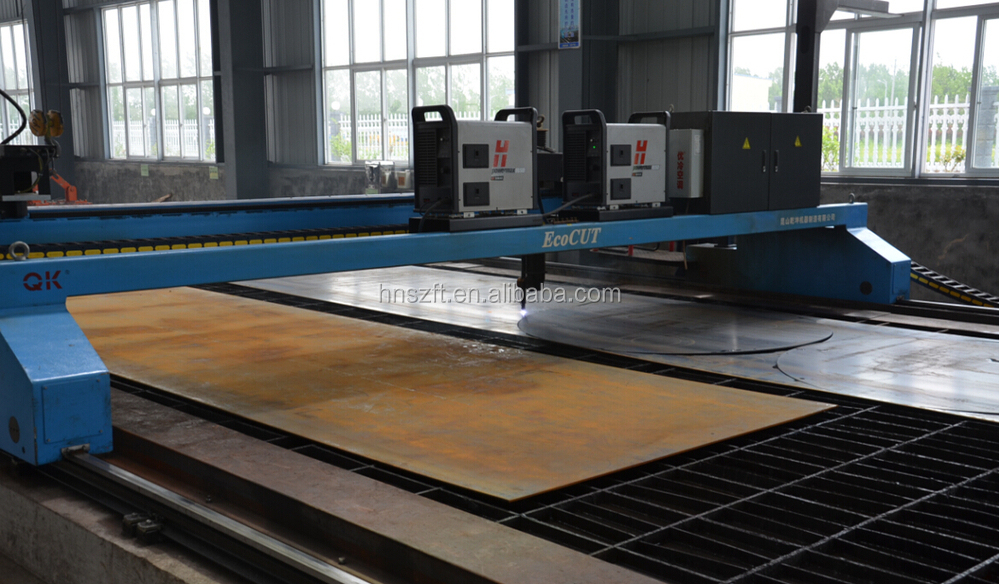

The NC Cutting machine

The Welding fixture

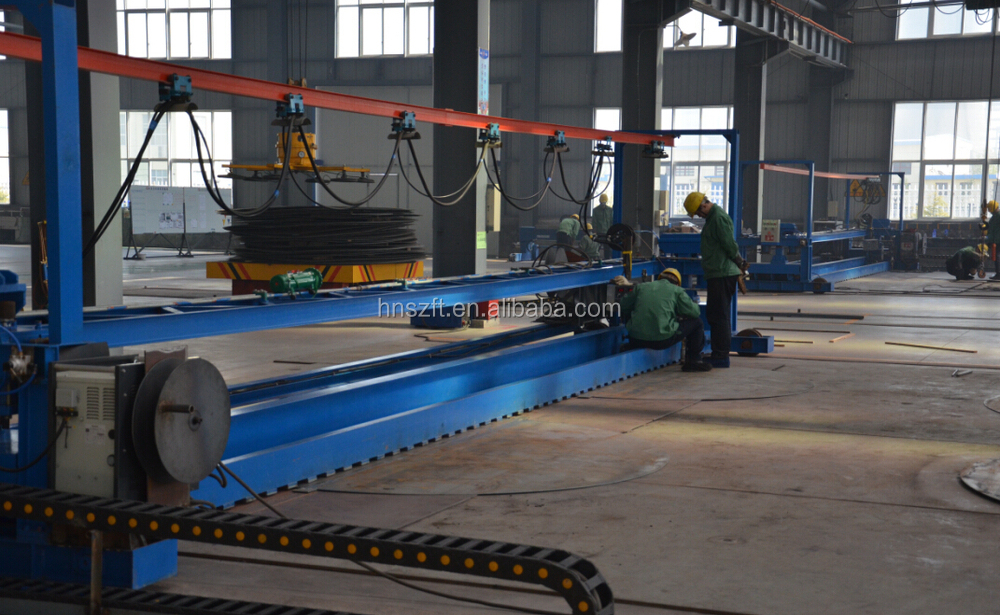

The (P+T) Automatic welding equipmet

![9{XDM[8~C}{]QI$$$O1`_RK.jpg](http://g03.s.alicdn.com/kf/HTB14JWqHXXXXXaqXXXXq6xXFXXXH/201002540/HTB14JWqHXXXXXaqXXXXq6xXFXXXH.jpg)

The Frequency converting control polishing equipment

![TF6MG`O{JW7G{`D9LO}R]L.jpg](http://g02.s.alicdn.com/kf/HTB1E4qqHXXXXXadXXXXq6xXFXXX9/201002540/HTB1E4qqHXXXXXadXXXXq6xXFXXX9.jpg)

The Scrubbing machine

![)J]E_~M[W`HKKGXW3O`DHOL.jpg](http://g02.s.alicdn.com/kf/HTB1c6unHXXXXXXhXpXXq6xXFXXXj/201002540/HTB1c6unHXXXXXXhXpXXq6xXFXXXj.jpg)

The Edge milling machine

The transloading equipment

The Inspection equipments

The Products display