Машина для изготовления оцинкованной проволоки/Производственная

- Категории: Other Metal & Metallurgy Machinery >>>

- Поставщик: Hebei,Greens,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

galvanized wire making machine/production line

Process:

1.Steel wire drawing machine

Application:

kinds varioushis device is uesd to draw various kinds of steel wire, welding wire and other metal wire materials.

Specification:

Times of drawing | Drum dia | Max inlet dia | Min outlet dia | Speed | Single power | Input strength |

2-11 | 300mm | 2.8mm | 0.5mm | 25m/s | 7.5-18.5KW | ≤1250MPA |

2-11 | 350mm | 3.5mm | 0.6mm | 20m/s | 11-12 KW | |

2-11 | 400mm | 4.2mm | 0.75mm | 20m/s | 11-30 KW | |

2-12 | 450mm | 5mm | 1mm | 16m/s | 15-37 KW | |

2-12 | 500mm | 5.5mm | 1.2mm | 15m/s | 22-45 KW | |

2-12 | 560mm | 6.5mm | 1.4mm | 15m/s | 22-55KW | |

2-12 | 600mm | 8mm | 1.6mm | 12m/s | 30-75KW | |

2-9 | 700mm | 10mm | 2.2mm | 12m/s | 45-90KW | |

2-9 | 800mm | 12.7mm | 2.6mm | 8m/s | 55-110KW |

Structure:

The equipment consists of main reduction box,die casing,wheel frame,sash brace and

electrical control system.The spinning drawing blocks are driven by JZT series motor,with gear coupling runs changeful gears to reduce speed. The drawing blocks are verticaly fixed in sealed box body.The gear pair are lubricated with oil.

2.Annealing furnace

Features:

This kind of furnace work periodically,and it is suitable for quenching,tempering,annealing of the steel parts,especially used for iron wire recrystallization annealing.

The advantage of an enery-saving resistance furnace lie in that the furnace lining is made of tufted fiber blanket,so it is of small heat absorption.And the thermoelectric components are hung in the hearth,which is fullexposed and directly irradiated,therefore its heat efficiency is high,and can save more than 30% of the energy than the traditional furnace.

Specification:

| power | 18-480kw |

| max working temperature | 900 |

| max diameter | 3500mm |

3.Galvanizing line

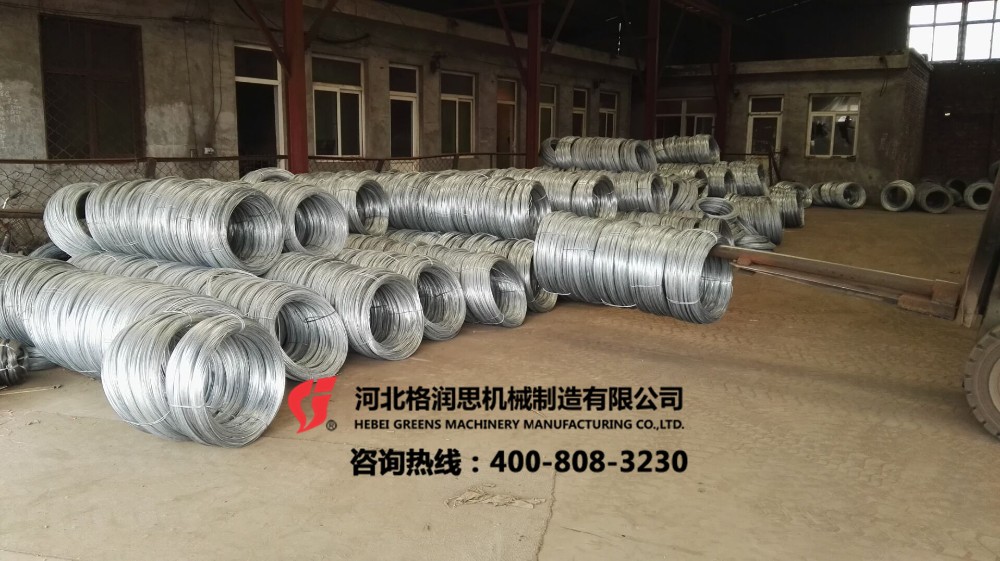

4.Final product

Contact information