XHH C305-310mm система пластин для холодной компонент формы легкая просторная шпренгельная конструкция стальная рама машины дома сборный дом из элементов

- Категории: Обрешечивающие машины и машины для стальной рамы >>>

- Поставщик: Xiamen,Xinhonghua,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

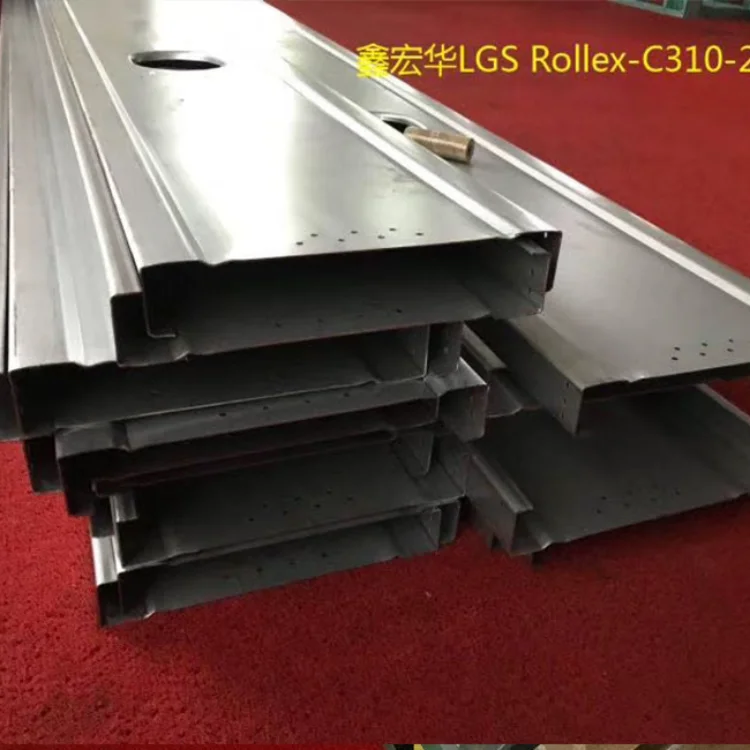

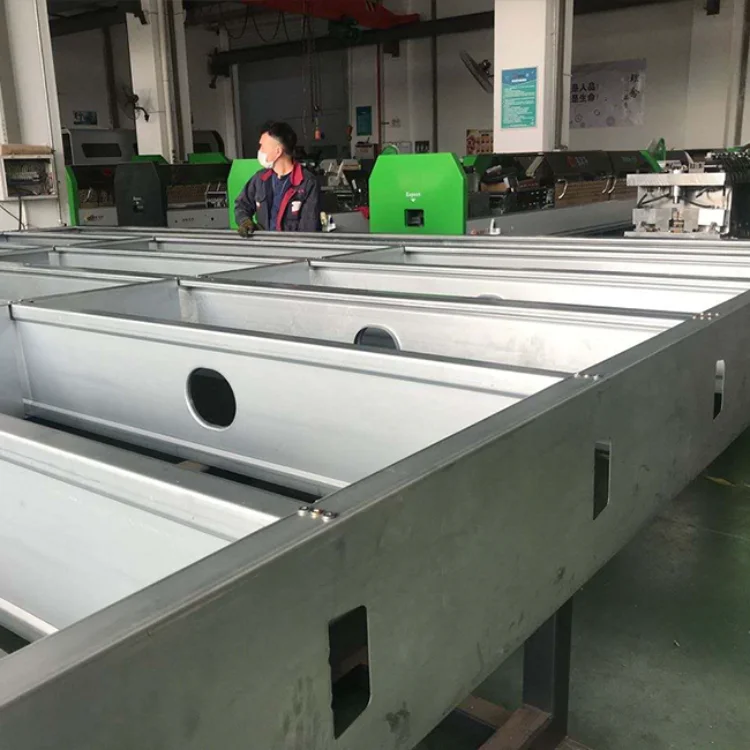

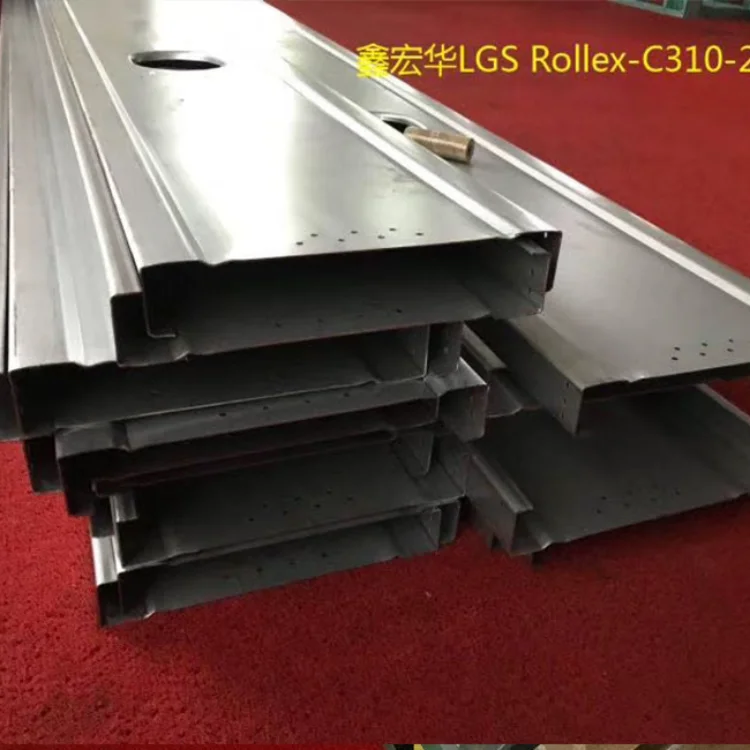

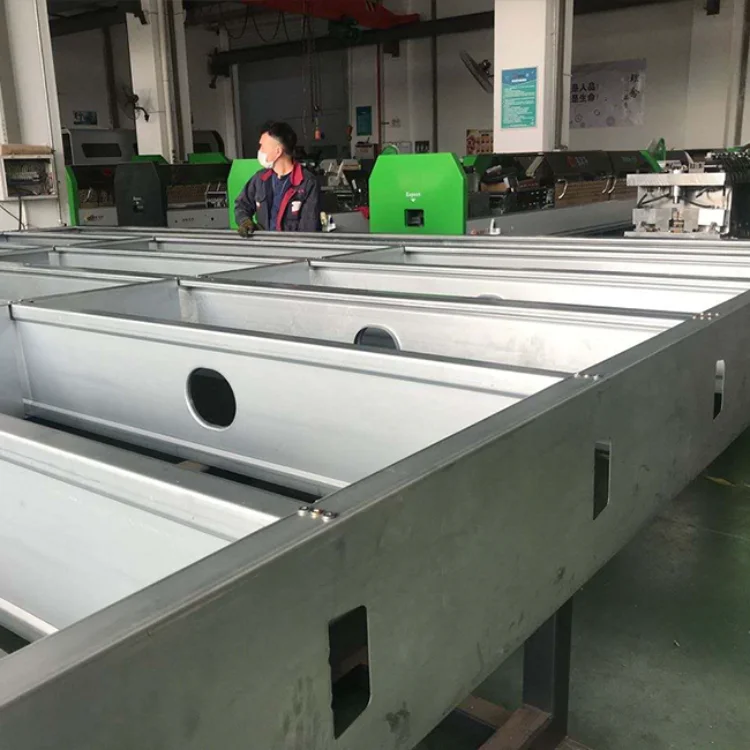

XHH C305-310mm Plate System Cold Form Component Light Gauge Steel Frame Machine For Prefabricated House

Main Technical Data

Size | C305/310 |

Dimension | 7600x1500x1700mm |

Main Servo Motor Power | 22KW |

Hydraulic Motor | 11kw |

Forming Steps | 12Steps |

Forming Speed | 15tons/8hours |

Voltage | 380V/50HZ/3PH |

Effective Width | 305mm,310mm |

Material Width | 425mm |

Flange Height | 50mm |

Lip | 12mm |

Material Thickness | G300-G450:0.95-2.5mm G550:0.95-2.0mm |

Tolerance for cutting and punching | ±1mm |

Tolerance for forming | ±1mm |

Control System | IPC Computer Controlling System |

Design Software | Vertex Software |

Material for All Roller | SKD-11 steel with heat treatment, plate hard chrome on the surface of rollers |

Material for Shaft | SKD-11 |

Material for Puncher | SKD-11 |

Material for Cutter | SKD-11 |

Features

l Post Punching Mould

XHH LGS Machine all with post punching and post cutting, which make more high precision performance on position & dimension

l Lower material wasting

Short distance between punching & cutting die able to limit the start-up material waste length at 0.2m, and end material waste length within 1 meter.

l Save Cost

The length of each start-up waste of the XHH post-punching & cutting machine is about 1M; most machines on the market are pre-punching & post-cutting (other supplier), their waste material is about 8m on each start-up

Start-Up/Change Steel Coil | 8.11-12.13 Kg |

5 Steel Coils/Day | 40.55-60.65 Kg |

Material Saved/Year | 12.17-18.2 T |

Main Accessories

1) Main Forming Machine |

2) 3 Tons Electric Uncoiler |

3) Servo Motor System |

4) IPC Computer Controlling System (Lenovo Laptop) |

5) Production Software (1set) |

6) Design Software-Vertex,forever using license |

7) Hydraulic Automatic Punching Device (Web/Lip Notch,Swage,Service Hole,Chamfer,Dimple,Bolt Hole) |

8) Hydraulic Post-cutting Device (Material:SKD-11) |

9) Automatic Printing Device |

10) Run Out Table (4m) |

11) Operation Manual |

Project

Related Products

XHH LGS Roll Former Series:

XHH-75 Model

XHH-89-5S Model

XHH-89-JC Model

XHH-140 Model

XHH-160 Model

XHH-310 Model