XHH C89 5S лгс Cad вес 7.5kw 300 МПа рамка машина для изготовления легких стальных тонкостенных конструкции дома сборный дом из элементов

- Категории: Steel Frame & Purlin Machines >>>

- Поставщик: Xiamen,Xinhonghua,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

XHH C89 5S Lgs Cad Weight 7.5kw 300 MPA Frame Light Gauge Steel Framing Machine For Prefabricated House

Main Technical Data

Size | C89 |

Dimension | 4200*800*1100mm |

Main Servo Motor Power | 7.5KW |

Hydraulic Motor | 7.5kw |

Forming Steps | 9Steps |

Forming Speed | 4-5tons/8hours |

Voltage | 380V/50HZ/3PH |

Effective Width | 89mm |

Material Width | 174mm |

Flange Height | 38mm |

Lip | 9mm |

Material Thickness | 0.6-1.2mm |

Tolerance for cutting and punching | ±0.5mm |

Tolerance for forming | ±0.75mm |

Control System | IPC Computer Controlling System |

Design Software | Vertex Software |

Material for All Roller | SKD-11 steel with heat treatment, plate hard chrome on the surface of rollers |

Material for Shaft | SKD-11 |

Material for Puncher | SKD-11 |

Material for Cutter | SKD-11 |

Features

l Post Punching Mould

XHH LGS Machine all with post punching and post cutting, which make more high precision performance on position & dimension

l Seamless end cut connection

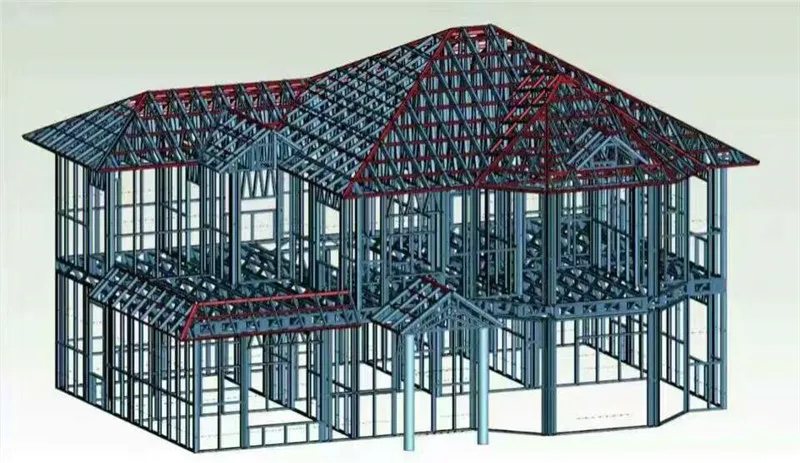

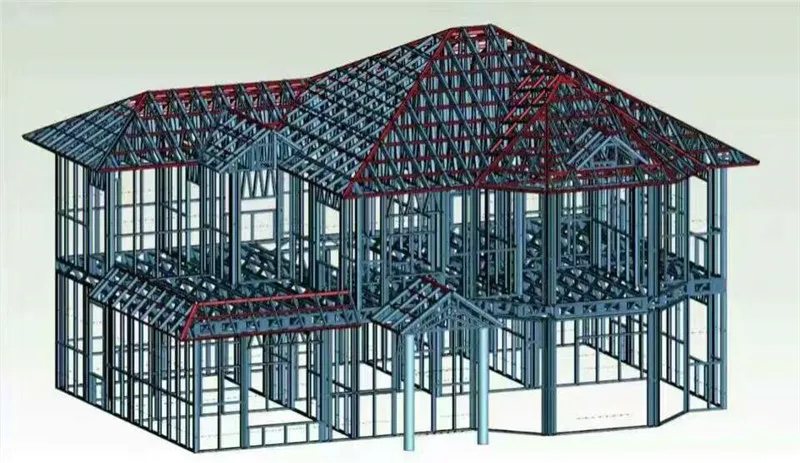

Seamless end-cut connection is a patent design of XHH LGS ROLL FORMER. The two ends of the vertical frame can seamlessly connect to the web of the bottom and top horizontal frames. So the weight of the house can be directly loaded and passed by the vertical frame, which makes the house safer.

l Continuous web notch punching without extruding material

The strength of raw material will be greatly reduced when continuous web & lip notches are made, thus material in the pre-punching machine may be easily extruded and then cause machine jam during roll forming process.XHH LGS Machine with post punching system,which we can do more continuous web notch even in 0.55mm thin thickness without extruding material.

l Lower material wasting

Short distance between punching & cutting die able to limit the start-up material waste length at 0.2m, and end material waste length within 1 meter.

l Save Cost

XHH Machine steel strip width is: 170-174mm width, 10mm less than the most other machines in the market. For a 200sqm house, the total frame is around 7000m,can save 439.6-659.4kg material

Material Thickness | 0.8mm | 1.0mm | 1.2mm |

Material Saved Per House | 439.6kg | 549.5kg | 659.4kg |

The length of each start-up waste of the XHH post-punching & cutting machine is about 1M; most machines on the market are pre-punching & post-cutting (other supplier), their waste material is about 8m on each start-up

Start-Up/Change Steel Coil | 8.11-12.13 Kg |

5 Steel Coils/Day | 40.55-60.65 Kg |

Material Saved/Year | 12.17-18.2 T |

Main Accessories

1) Main Forming Machine |

2) 3 Tons Electric Uncoiler |

3) Servo Motor System |

4) IPC Computer Controlling System (Lenovo Laptop) |

5) Production Software (1set) |

6) Design Software-Vertex,forever using license |

7) Hydraulic Automatic Punching Device (Web/Lip Notch,Swage,Service Hole,Chamfer,Dimple,Bolt Hole) |

8) Hydraulic Post-cutting Device (Material:SKD-11) |

9) Automatic Printing Device |

10) Run Out Table (4m) |

11) Operation Manual |

Project

Related Products

XHH LGS Roll Former Series:

XHH-75 Model

XHH-89-5S Model

XHH-89-JC Model

XHH-140 Model

XHH-160 Model

XHH-310 Model