Жидкость для пескоструйной обработки воды жидкостно-пескоструйной

- Категории: >>>

- Поставщик: Hangzhou,Color,Powder,Coating,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

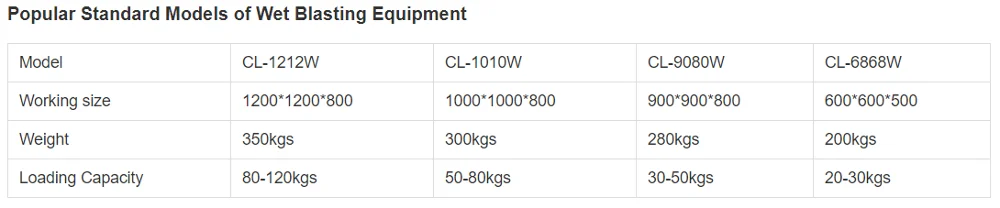

COLO8070W Dustless wet blasting cabinet

![]()

Wet Abrasive Blasting Cabinet, Dust-free Blasting Cabinet

The working principle of Wet blasting cabinet is abrasive mixed with water in a slurry pump. The pump push the mixture to the blasting nozzle, while compressed air power accelerate the mixture to the product surface. The obvious advantages of wet blasting process is:

1. Dust free, The bringing of water reduces the dust, keep a clean working environment

2. Decrease the friction heat to prevent color changes for same special metal workpieces.

3. Eliminate the surface removal of delicated parts, maintain a more precise shape.

4. Any Ultra-fine abrasive can be used while dry blaster can not achieve.

Dustless Wet Blasting Cabinet Features

>Make the product surface more delicate and clean, because of water's cushion and washing.

>Does not cause pollution to the environment and protect the health of operator.

>Compact model, foot controlled working of blast gub, easy to operate, safe and reliable.

>Stainless steel body, anti-rust. The working chamber is equipped with a rubber plate to prevent the jet impact.

>High-class abrasive pumps, blast guns, gun nozzle (with boron carbide material), workbenches(contains wearing-resistant materials - polyurethane), long life to ensure reliable performance.

>Abrasive can be effectively recycled, less consumption, reduce production cost.

>The wet blasting cabinet is Simple structure, requires less maintenance.

Wet Abrasive Blasting Cabinet Application

Wet sandblasting equipment is applied for the products which need surface cleaning or renovating, like forgings, castings, welded parts, electrical parts, stainless steel products, aluminum products, plastic products, crystal glass products, or metal products.

Abrasives use: white corundum, brown aluminum axide, black corundum, plastic abrasive, ceramic sand, etc.

![]()

![]()

![]()