Новый стиль универсальный фрезерный станок

- Категории: Manual Mills >>>

- Поставщик: Zaozhuang,DS,Machine,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

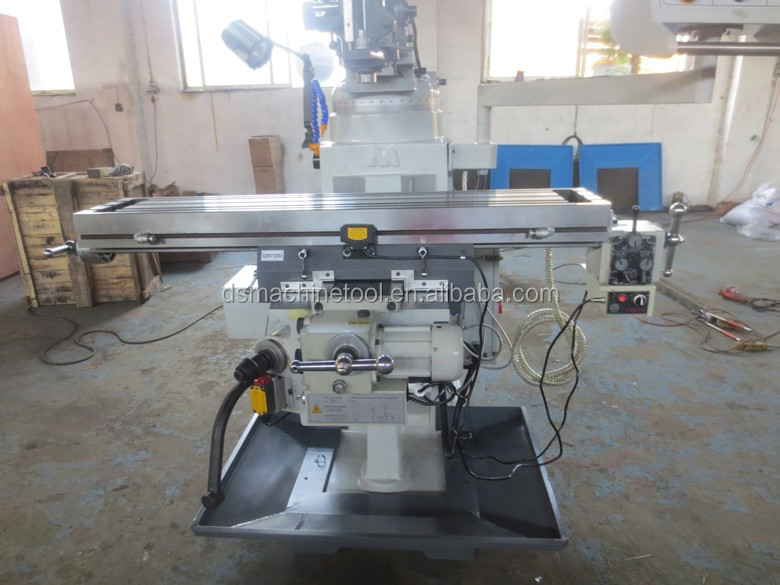

New style Turret Universal milling machine X6325

Features:

1. 2.2kw (3hp) Taiwan high speed milling head

2. Vertical milling spindle automatic feed

3. milling head can tilt :Left / right ±90°; forward / backward ±45°

4..Cost-effective machine

5. High stability

Performance:

1.Multi-purpose milling machines for workshop, single part production, design and training;

2.Universal use;

3.Head swivel through 2 axes, swivel: 90 degree; tilt: 45 degree;

4.More rigid and powerful with (X6325) 2.2KW / (X6330) 3.7KW motor;

5.X6325 Spindle Taper ISO30/R8

X6330 Spindle taper:ISO40/NT40

6.Manual coarse feed for quill, toggles to micro-feed;

7.Infinitely variable speed as optional;

8.Auto quill feed with 3 steps.

9. X6325: rectangular way on Y axis slideway, swallow tail way on Z axis slideway

X6330:rectangular way on Y Z axis slideway.

10. Hardened and ground work table

11. Hardened and ground on XYZ axis slide ways

Specifications | X6325 |

Table size (mm) | 1270*254 or 1370*254 |

Travel(XYZ) (mm) | 750 (max:850)*400*400 |

T-Slot Numbe / width / spacing (mm) | 3 / 16 / 65 |

Max.table load (KG) | 350 |

Ram travel (mm) | 400mm |

Distance from spindle nose totable top (mm) | 0-460 |

Distance from spindle to column (mm) | 155-635 |

Spindle taper | (Standard): R8/ISO30 (Optional): ISO40 |

Spindle travel | 127mm |

Spindle speed range (r.p.m) | 66-4540 (16 steps) |

Milling head tilt (left/right) | 90° |

Milling head tilt ( front / back) | 45° |

Spindle Motor (HP) | 3 |

N.W/G.W (KG) | 1200/1300 |

Packing size (mm) | 1450*1650*2200 |

Accessories: |

1.mill chuck(8pcs) 2.machine vice(160mm) |

3.machine light 4. clamping kit (58pcs) |

5.coolant pump |

6.chip tray |

7.Electrical panel |

8.tool box |

9.bellow cover |

10.Draw bar |

11.Handle oil pump |

12. Operation manual |

As Blow is our X6325 with the optional accessories some pictures:

Mechanical power feed on X and Y axis, Z axis lifting and lowering:

New control panel, easier control, more beautiful

Rust-proof oil + plasticbag + fumigation-free wooden boxes+ wooden pallets/iron pallets;

The packing similar as below pictures

Customized services

We accept customized services around the world

After-sale services

1. Technical support online service provided.

2. Technical files service provided.

3. Spare parts replacement and repair service provided.

4. Questions will be replied within 24 hours

We will supply enough spare parts and accessories with our machine when shipment. Within one year after receiving our machine, If there are any damaged parts or accessoreis, We will supply them to you by air-mail free of charge.

Every month, we will export almost 20 sets different kinds machine in the worldwide.

We think we can give you the most comprehensive support not only service but also techniques.

View more about: www.dsmachinetool.com

1. Delivery Time:

For one set machine, will be within 25-30 days after deposit.

For 5-10 sets same machines, will be within 35-40 days after deposit.

For 5-10 sets different machine, will be within 35-40 days after deposit.

2. MOQ:

1 set machine.

If you need machine with your own: logo, brand, model etc,please negotiate with us.

3. Shipping:

For machine: Usually by sea;

For documents: by international express, such as: DHL,UPS,TNT,EMS,FEDEX

4.Machine color and voltage:

we can according customer requirement.