Refractory Sic tube / silicon carbide beam used in sanitary ware

- Категории: Огнеупорные материалы >>>

- Поставщик: Zibo,Supereal,Industrial,Ceramic,Co.,Ltd.Zibo,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace

1. Technical parameters of reaction bonded silicon carbide RBSIC :

| ITEM | UNIT | DATA |

| Name | Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace | |

| Temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Open Porosity | % | <0.1 |

| Moh's Scale of Hardness | 13 | |

| Bending Strength | MPa | 250 (20℃) |

| MPa | 280 (1200℃) | |

| Modulus of Elasticity | GPa | 330 (20℃) |

| GPa | 300 (1200℃) | |

| Thermal Conductivity | W/m.k | 45 (1200℃) |

| Coefficient of thermal expansion | k-1×10-6 | 4.5 |

| Acid Alkaline -proof | Excellent | |

Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace are used for the loading structure systems of tunnel kilns, shuttle kilns and many other industrial kilns. RBSIC ceramic cross beams have higher strength and there are no deformations even at high emperatures, and also the beams display ver long service life. They are the most suitable kiln furnature for sanitarywear and electrical porcelain applications.Besides, RBSIC beams have excellent thermal conductivity, so it is available to save energy with less weight of the kiln car.

2. Main Specification of Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace

Bearing Capacity of RBSIC ( SiSiC) Beams

| Name | Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace | |||||

| Section Size (mm) | Wall (mm) | Concentrated Loading (kg/m) | Uniformly Distributed (kg/m) | |||

| Width | Height | Thickness | Width | Height | Width | Height |

| 30 | 30 | 5 | 72 | 72 | 144 | 144 |

| 30 | 40 | 5 | 115 | 93 | 130 | 186 |

| 40 | 40 | 6 | 162 | 162 | 324 | 324 |

| 40 | 50 | 6 | 231 | 197 | 462 | 394 |

| 40 | 60 | 6 | 308 | 232 | 616 | 464 |

| 50 | 60 | 7 | 405 | 357 | 810 | 714 |

| 50 | 70 | 8 | 562 | 442 | 1124 | 884 |

| 60 | 90 | 9 | 1039 | 784 | 2078 | 1568 |

| 80 | 100 | 10 | 1643 | 1413 | 3286 | 2826 |

| 120 | 120 | 12 | 3401 | 3401 | 6802 | 6802 |

3.Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace Property:

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

The reaction bonded silicion carbide ceramic ( RBSIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive, coarse particles, classification, concentration, dehydration and other operations. Due to the above properties, the reaction bonded silicon carbide RBSIC wear resistant ceramic tubes can effectively protect the part from high wear so as to prolong the service life of the equipment.

4. Packing of Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace

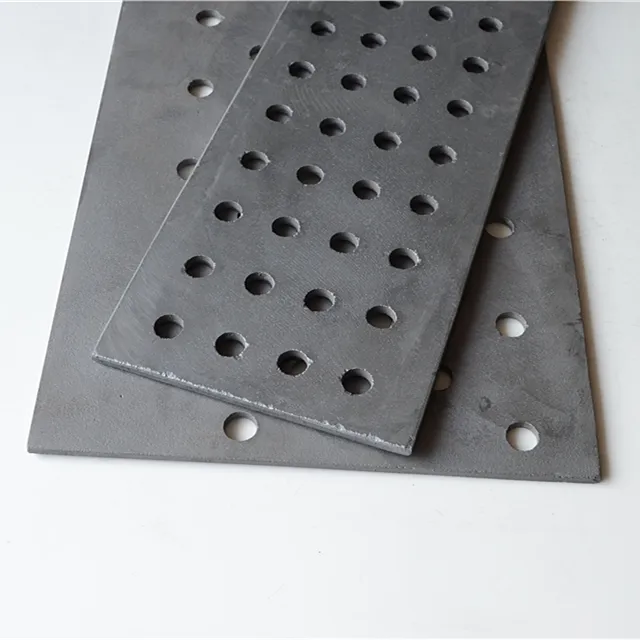

5. Specification of reaction bonded silicion carbide ceramic ( RBSIC)

Thickness available: 6mm - 25mm

Shape available: screw, plain plate, straight pipe, tee pipes, ring, elbow, cone cyclone and so on.

Remark: Other sizes and shape are available upon requests.

Some RBSIC ceramic parts show:

6. Main Application

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

Wear Resistant Linings Supports

The RBSIC ceramic products are widely used in high temperature ceramic kiln,steel quench furnace,large boiler,power plant desulfurization dusting equipment and high-tech military equipment. The industry involves but not limited to daily-use ceramics, sanitary ceramics,porcelain insulator,crystallite glass, metallurgy, magnetic materials, electric power, chemical industry, steel, petroleum, machinery, military industry,etc.

Zibo Supereal Industrial Co., Ltd, located in Zhangdian Economic Development Zone in Zibo city is focusing on silicon carbide ceramic products ( such as RBSIC burner nozzles,desulphurization nozzles,Refractory Sic tube / silicon carbide beam / Sic beam used in sanitary ware furnace ,rollers,thermocouple protection tubes,cooling air pipes,RBSIC cyclone lining tubes/ceramic liners,silicon carbide batts and plates and other special shaped parts) . Here you can realize an one-stop shopping for complete wear and erosion protection solutions in wide range of industries including Power Sector, Mining, Cement, Metallurgy, Coal Washing, Steel& Iron Plant, Railway, Port and so on.

As a professional supplier we can promptly supply tailor-made wear protection solutions according to the actual working conditions and requirements to solve the customer’s common problems or particular problems in bulk materials handling or conveying, including to choose the appropriate wear resistant materials, connection method, reasonable and optimum design, stable hand high quality manufactured and perfect after-sales service, all of which are aimed to help users to improve the operational efficiency and service life of devices or equipments.

Our company has a rigorous quality control system to guarantee stable performance and proven quality, our professional inspection team will carry out full course tracking from raw material selection, batching, production process management to semi and finished products test. Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our products have been approved and accepted by clients and users from Australia, South Korea, India, Russia, South Africa, Turkey, USA, France and etc.

Besides the superior quality, Zibo Supereal Industrial Co., Ltd also earned a good reputation for fast deliveries, competitive pricing and outstanding customer service.

◊ Professional: More than ten years of experience in production, more than 5 years of experience in foreign trade export, we will supply prompt technical support on pre- and after sales.

◊ High Quality:Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our inspection engineers carry out full course tracking in the whole production.

◊ Focus on Details: No matter how small questions or problems shall be replied and help to solve by our members, even for the small orders.

◊ Price &Discount: We can provide competitive price and discount for large quantity.

◊ OEM : Customized designs, sizes and logos are acceptable.